To prevent physical damage during storage, your all-PTFE electrolytic cell must be protected from sustained pressure or weight. Because PTFE is a relatively soft material, placing heavy objects on it or storing it in a cramped space can cause permanent deformation, known as "creep," which can compromise the integrity of its seals and ruin its experimental viability.

The core principle is to treat your all-PTFE cell not as a rugged, indestructible object, but as a precision instrument. Its primary vulnerability is physical deformation, and proper storage is essential to preserving the exact shape required for a reliable seal.

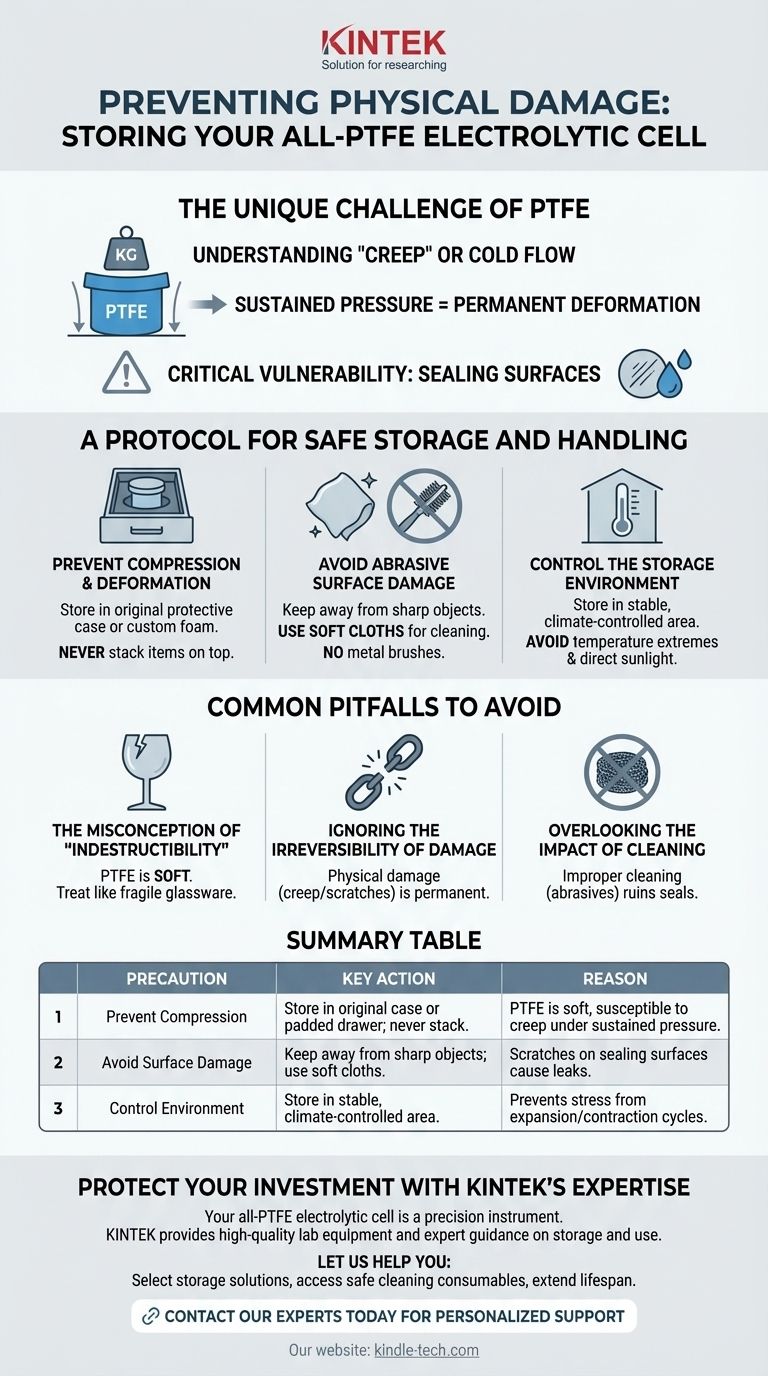

The Unique Challenge of PTFE

Polytetrafluoroethylene (PTFE) is prized for its extreme chemical inertness and temperature resistance. However, these properties come from a molecular structure that also makes the material physically soft and susceptible to certain types of damage that would not affect glass or metal.

Understanding "Creep" or Cold Flow

PTFE exhibits a phenomenon called creep, or cold flow. This means that under sustained pressure, even at room temperature, the material will slowly deform and will not return to its original shape.

This is the single most important factor to consider for storage. A cell body that has warped, even slightly, may no longer seal correctly with its lid or fittings, rendering it useless for controlled experiments.

The Vulnerability of Sealing Surfaces

The most critical parts of your cell are the precision-machined surfaces that form the seals. These surfaces must be perfectly flat and smooth to function.

Scratches, nicks, or warping on these faces create pathways for leaks, compromising the controlled environment essential for electrochemical analysis.

A Protocol for Safe Storage and Handling

A consistent protocol is the best way to ensure the longevity and reliability of your equipment. The goal is to protect the cell from both deformation and surface damage.

Prevent Compression and Deformation

Always store the cell in a way that it supports only its own weight. Never stack other equipment on top of it, no matter how light.

Ideally, store the cell in its original protective case or a dedicated, custom-cut foam insert inside a drawer or cabinet. This prevents accidental pressure from surrounding items.

Avoid Abrasive Surface Damage

While this is most critical during cleaning, the principle applies to storage as well. Ensure the cell is not stored in contact with sharp or hard objects, such as metal tools, clamps, or other labware.

Never use metal brushes or abrasive pads to clean the cell, as any scratches on the sealing surfaces are permanent and can lead to seal failure.

Control the Storage Environment

Although PTFE has a wide operating temperature range, storing it in a stable, climate-controlled environment is best practice.

Avoid storing the cell in areas with extreme temperature fluctuations, such as in direct sunlight or near heating vents. This helps prevent any unnecessary expansion and contraction cycles that could stress the material over time.

Common Pitfalls to Avoid

Understanding common mistakes is as important as knowing the correct procedures. Many cells are damaged due to simple misunderstandings about the material's properties.

The Misconception of "Indestructibility"

Users often mistake PTFE's incredible chemical resistance for physical toughness. It is vital to remember that PTFE is a soft polymer. Handling it with the same care you would use for fragile glassware is a good rule of thumb.

Ignoring the Irreversibility of Damage

Physical damage to PTFE, whether from deformation or deep scratches, is typically irreversible. Unlike glass, it cannot be re-blown, and unlike metal, its surfaces cannot be easily re-polished without specialized machining. A damaged cell is often a lost investment.

Overlooking the Impact of Cleaning

Improper cleaning is a primary source of physical damage. Using a metal spatula to scrape residue or a steel wool pad to scrub a surface can instantly ruin the cell's sealing capability. Stick to soft cloths, polymer-safe solvents, and gentle wiping.

Making the Right Choice for Your Goal

Your storage strategy should align with your lab's priorities.

- If your primary focus is maximum longevity and data integrity: Store the cell disassembled in a dedicated, padded case that prevents any part from bearing weight. This is the gold standard for long-term preservation.

- If your primary focus is frequent use and convenience: Designate a specific, protected shelf or drawer for the cell. Ensure it has enough clearance on all sides so it cannot be bumped, crushed, or have other items placed on it.

- If your primary focus is maintaining experimental consistency: Before each use, perform a quick visual inspection of all sealing surfaces for signs of warping, discoloration, or scratches that could indicate improper storage or handling.

By understanding the unique properties of PTFE, you can easily protect your equipment and ensure it delivers reliable results for years to come.

Summary Table:

| Precaution | Key Action | Reason |

|---|---|---|

| Prevent Compression | Store in original case or padded drawer; never stack items on it. | PTFE is soft and susceptible to permanent deformation (creep) under sustained pressure. |

| Avoid Surface Damage | Keep away from sharp objects; use soft cloths for cleaning. | Scratches on sealing surfaces can cause leaks and ruin experimental integrity. |

| Control Environment | Store in a stable, climate-controlled area away from temperature extremes. | Prevents stress from expansion/contraction cycles that could weaken the material over time. |

Protect your investment and ensure experimental accuracy with KINTEK's expertise.

Your all-PTFE electrolytic cell is a precision instrument requiring specialized care. At KINTEK, we understand the critical importance of maintaining lab equipment for reliable, repeatable results. We specialize in providing high-quality lab equipment and consumables, along with expert guidance on their proper use and storage.

Let us help you:

- Select the right storage solutions to prevent PTFE deformation.

- Access cleaning consumables that are safe for sensitive surfaces.

- Extend the lifespan of your valuable lab equipment.

Don't let improper storage compromise your research. Contact our experts today for personalized support and ensure your lab operates at its best.

Visual Guide

Related Products

- PTFE Electrolytic Cell Electrochemical Cell Corrosion-Resistant Sealed and Non-Sealed

- Electrolytic Electrochemical Cell with Five-Port

- Electrolytic Electrochemical Cell Gas Diffusion Liquid Flow Reaction Cell

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- Electrolytic Electrochemical Cell for Coating Evaluation

People Also Ask

- What are the key material properties and structural features of an all-PTFE electrolytic cell? Achieve Unmatched Purity in Harsh Electrochemical Environments

- How should an all-PTFE electrolytic cell be handled to prevent mechanical damage? Protect Your Investment and Data Integrity

- What inspection steps should be performed on an all-PTFE electrolytic cell before use? Ensure Reliable Results

- What materials are used for the body of a super-sealed electrolytic cell and what are their properties? Select the Right Material for Your Experiment

- How should an all-PTFE electrolytic cell be cleaned before use? Expert Protocol for Pure Electrochemical Results