At its core, an all-PTFE electrolytic cell is defined by three primary characteristics: extreme chemical inertness, excellent electrical insulation, and a wide operational temperature range. Constructed entirely from polytetrafluoroethylene (PTFE), these cells are specifically designed to operate in harsh electrochemical environments where other materials would quickly corrode, contaminate the experiment, or fail structurally.

The decision to use an all-PTFE electrolytic cell is a strategic choice for uncompromised chemical purity and operational stability. It is the go-to solution when the integrity of the experiment cannot be risked by material degradation or contamination from the cell itself.

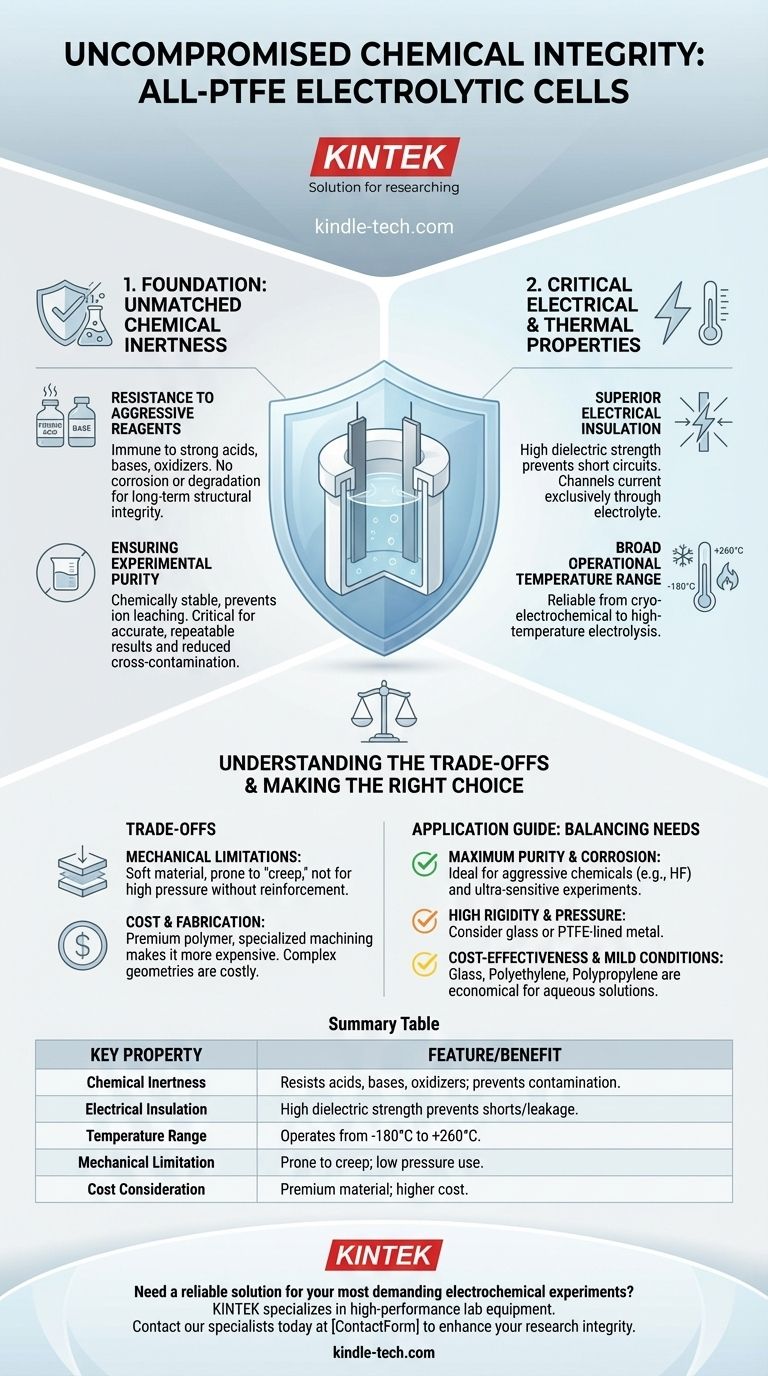

The Foundation: Unmatched Chemical Inertness

The most significant advantage of an all-PTFE cell is its near-universal resistance to chemical attack. This property is fundamental to its role in advanced electrochemistry.

Resistance to Aggressive Reagents

PTFE is virtually immune to attack from the most aggressive chemicals, including strong acids, strong bases, and powerful oxidizing and reducing agents.

Unlike metals or other polymers, it will not corrode or degrade, ensuring the structural integrity of the cell over long-term use in demanding conditions.

Ensuring Experimental Purity

Because PTFE is chemically stable and does not react with the electrolyte, it prevents leaching of ions or organic compounds into the solution.

This inertness is critical for obtaining accurate and repeatable results, as it eliminates the risk of the cell itself becoming a source of contamination. Its non-stick surface also simplifies cleaning and reduces cross-contamination between experiments.

Critical Electrical and Thermal Properties

Beyond chemical stability, PTFE’s physical properties make it uniquely suited for electrolytic applications. These features ensure the cell operates safely and effectively under a wide range of conditions.

Superior Electrical Insulation

PTFE possesses exceptionally high dielectric strength, making it an outstanding electrical insulator. This property is crucial for preventing short circuits between the electrodes within the cell.

Furthermore, its insulating nature prevents electrical leakage to the surrounding environment, ensuring that the applied current is channeled exclusively through the electrolyte for an efficient and controlled reaction.

Broad Operational Temperature Range

An all-PTFE cell can function reliably across an exceptionally wide temperature spectrum, typically from -180°C to +260°C.

This thermal stability allows for its use in both high-temperature electrolysis and cryo-electrochemical studies, applications where most other plastic materials would become brittle or melt.

Understanding the Trade-offs

While its properties are exceptional, choosing an all-PTFE cell involves understanding its inherent limitations. No material is perfect for every scenario.

Mechanical Limitations

PTFE is a relatively soft material with a tendency to "creep" or deform over time, especially under mechanical load and at elevated temperatures. It is not suitable for high-pressure applications without structural reinforcement.

Cost and Fabrication

PTFE is a premium polymer, and the raw material and specialized machining required to fabricate a cell make it more expensive than cells made from glass or other plastics like polypropylene.

Complex geometries can be particularly challenging and costly to produce, which may limit design possibilities compared to more easily molded materials.

Making the Right Choice for Your Application

Selecting the appropriate cell material requires balancing experimental needs with material properties and cost.

- If your primary focus is maximum purity and corrosion resistance: An all-PTFE cell is the definitive choice for working with aggressive chemicals like hydrofluoric acid or when any level of ionic contamination would invalidate your results.

- If your primary focus is high structural rigidity or pressure: You should consider a glass cell or a PTFE-lined metal vessel that provides the necessary mechanical strength while still offering a chemically inert surface.

- If your primary focus is cost-effectiveness in mild conditions: For aqueous solutions and less aggressive electrolytes, cells made from glass, polyethylene, or polypropylene offer a more economical solution.

Ultimately, an all-PTFE electrolytic cell is the standard for when your experiment demands the highest degree of chemical and electrical integrity.

Summary Table:

| Key Property | Feature/Benefit |

|---|---|

| Chemical Inertness | Resists strong acids, bases, and oxidizers; prevents contamination. |

| Electrical Insulation | High dielectric strength prevents short circuits and current leakage. |

| Temperature Range | Operates reliably from -180°C to +260°C. |

| Mechanical Limitation | Prone to creep; not suitable for high-pressure use without reinforcement. |

| Cost Consideration | Premium material; more expensive than glass or polypropylene cells. |

Need a reliable solution for your most demanding electrochemical experiments?

KINTEK specializes in high-performance lab equipment, including electrolytic cells designed for purity and stability. If your work involves aggressive chemicals like hydrofluoric acid or requires uncompromised results free from contamination, our expertise can help you select the right equipment.

Contact our specialists today to discuss how our solutions can enhance the integrity and success of your research.

Visual Guide

Related Products

- PTFE Electrolytic Cell Electrochemical Cell Corrosion-Resistant Sealed and Non-Sealed

- Electrolytic Electrochemical Cell with Five-Port

- Electrolytic Electrochemical Cell for Coating Evaluation

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

People Also Ask

- What inspection steps should be performed on an all-PTFE electrolytic cell before use? Ensure Reliable Results

- What is the precaution regarding temperature when using an all-PTFE electrolytic cell? Essential Thermal Safety Tips

- How should an all-PTFE electrolytic cell be cleaned before use? Expert Protocol for Pure Electrochemical Results

- What are the standard opening specifications for all-PTFE electrolytic cells? A Guide to Sealed vs. Non-Sealed Ports

- How should an all-PTFE electrolytic cell be handled to prevent mechanical damage? Protect Your Investment and Data Integrity