The proper method for cleaning an all-PTFE electrolytic cell involves a multi-step rinsing process using deionized water and, when necessary, a suitable non-abrasive solvent. The most critical rule is to avoid any abrasive tools, like metal brushes or steel wool, that could scratch the inert PTFE surface and compromise future experiments.

The core principle of cleaning a PTFE cell is to completely remove chemical residues from the previous experiment without altering or damaging the cell's physically inert surface. Scratches create active sites for contamination, undermining the very reason for using PTFE in the first place.

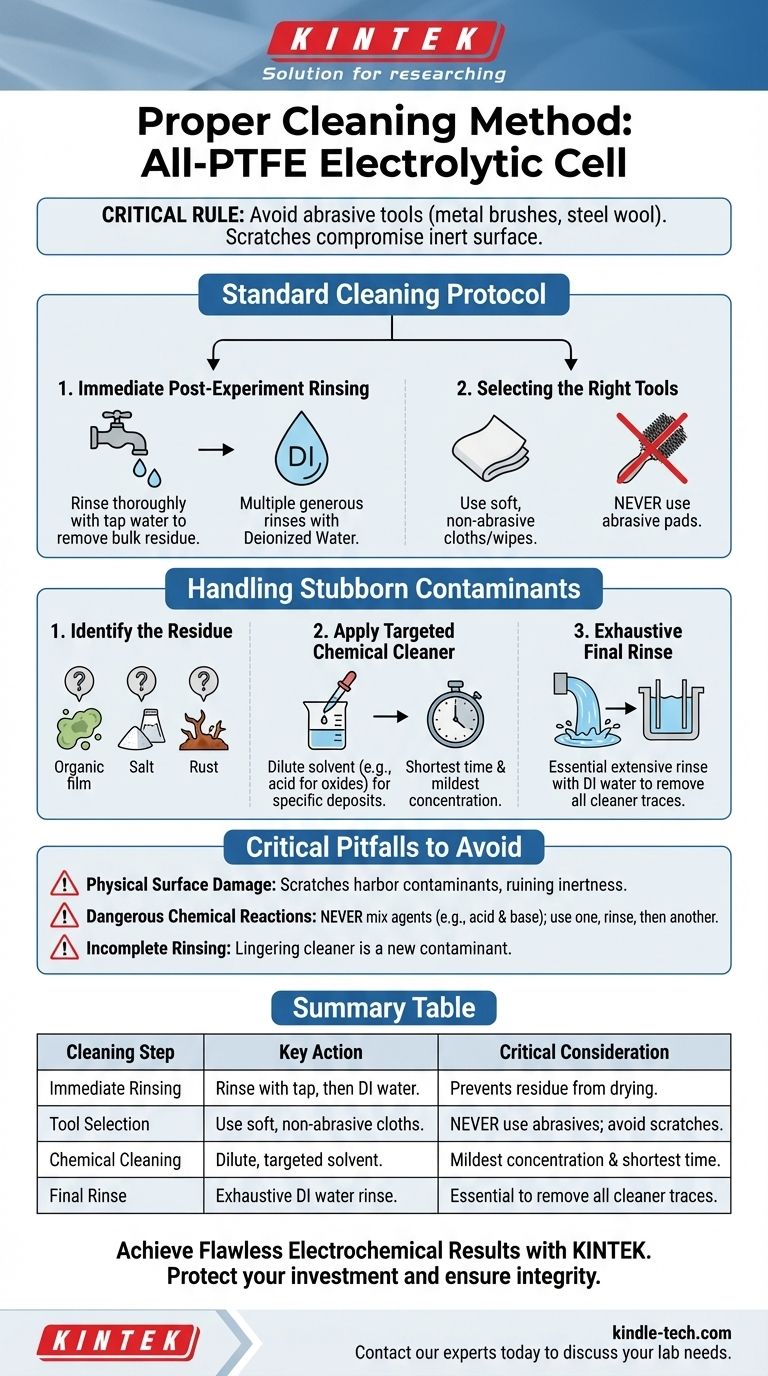

The Standard Cleaning Protocol

Proper maintenance begins immediately after an experiment concludes. Delaying cleaning allows residues to dry and adhere more strongly to the cell walls and electrodes.

Step 1: Immediate Post-Experiment Rinsing

The first and most important step is to prevent buildup.

Rinse all cell components thoroughly with tap water to remove the bulk of the residual electrolyte and reaction products.

Follow this immediately with multiple, generous rinses using deionized (DI) or distilled water. This removes any ions or impurities present in tap water.

Step 2: Selecting the Right Tools

The physical integrity of the PTFE surface is paramount.

Never use metal brushes, steel wool, or any abrasive pads for cleaning. These will create micro-scratches that can trap contaminants and affect electrochemical measurements.

Use soft cloths or wipes designed for laboratory use if physical wiping is necessary.

Handling Stubborn Contaminants

Sometimes, simple rinsing isn't enough to remove all deposits, especially after certain electrochemical reactions. This requires a more targeted chemical approach.

Step 1: Identify the Residue

Before choosing a cleaning agent, you must know what you are trying to remove. Is it an organic film, a salt precipitate, or a metal oxide like rust?

The nature of the deposit dictates the appropriate chemical cleaner.

Step 2: Apply a Targeted Chemical Cleaner

For stubborn inorganic deposits like iron oxides, a dilute acid (e.g., hydrochloric acid) can be effective.

It is crucial to control both the concentration of the chemical and the duration of its contact with the cell. Use the mildest effective concentration for the shortest possible time.

Step 3: Perform an Exhaustive Final Rinse

After any chemical cleaning, the cell must be rinsed with a large volume of deionized water.

This final rinse is not optional; it is essential to ensure no residue from the cleaning agent remains, as that would simply replace one contaminant with another.

Critical Pitfalls to Avoid

Mistakes during cleaning can be costly, leading to inaccurate results or a damaged cell. Understanding what not to do is as important as knowing the correct procedure.

Physical Surface Damage

As emphasized, scratching the PTFE surface is the most common and damaging error. A scratched surface is no longer truly inert, as it can harbor ions and molecules that interfere with subsequent experiments.

Dangerous Chemical Reactions

Never mix different cleaning agents, especially acids and bases (like nitric acid and sodium hydroxide). This can trigger a dangerous and uncontrolled exothermic reaction.

Clean with one agent, rinse thoroughly, and then use another if necessary.

Incomplete Rinsing

Failing to completely rinse away a chemical cleaning agent can be worse than leaving the original residue. The lingering cleaner can actively participate in the next experiment, corrupting your data.

A Cleaning Strategy for Your Goal

Your cleaning protocol should adapt to the specific type of contamination you face.

- If your primary focus is routine, post-experiment cleanup: An immediate and thorough rinse with tap water followed by multiple deionized water rinses is sufficient.

- If you are dealing with stubborn organic films: Use an appropriate solvent known to dissolve the residue, followed by an exhaustive deionized water rinse.

- If you must remove inorganic deposits like metal oxides: Use a carefully selected and controlled dilute chemical cleaner, followed by a final, extensive rinse with deionized water to remove all traces.

A meticulously clean cell is the foundation of reliable and reproducible electrochemical data.

Summary Table:

| Cleaning Step | Key Action | Critical Consideration |

|---|---|---|

| Immediate Rinsing | Rinse with tap water, then deionized water. | Prevents residue from drying and adhering. |

| Tool Selection | Use only soft, non-abrasive cloths or wipes. | NEVER use metal brushes or abrasive pads to avoid scratches. |

| Chemical Cleaning | Apply a dilute, targeted solvent (e.g., acid for oxides). | Use mildest concentration for shortest time; identify residue first. |

| Final Rinse | Perform exhaustive rinse with deionized water. | Essential to remove all traces of the cleaning agent itself. |

Achieve Flawless Electrochemical Results with KINTEK

A meticulously clean PTFE electrolytic cell is non-negotiable for reliable data. At KINTEK, we specialize in the high-quality lab equipment and consumables that your research depends on.

We understand your challenges: Contamination and surface damage can compromise months of work. Let us help you protect your investment and ensure the integrity of your experiments.

We provide the solutions: From durable PTFE cells to the right cleaning accessories, KINTEK is your partner for precision and reliability in the laboratory.

Don't let improper cleaning undermine your science. Contact our experts today to discuss your specific lab needs and discover how KINTEK can support your success.

Visual Guide

Related Products

- Electrolytic Electrochemical Cell with Five-Port

- PTFE Electrolytic Cell Electrochemical Cell Corrosion-Resistant Sealed and Non-Sealed

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- Electrolytic Electrochemical Cell for Coating Evaluation

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

People Also Ask

- What material is the five-port water bath electrolytic cell made of? High Borosilicate Glass & PTFE Explained

- How should the five-port water bath electrolytic cell be cleaned for maintenance? A Step-by-Step Guide to Reliable Results

- How can contamination be avoided during experiments with the five-port water bath electrolytic cell? Master the 3-Pillar Protocol

- How can leaks be prevented when using a five-port water bath electrolytic cell? Ensure a Reliable and Safe Electrochemical Setup

- What general precaution should be taken when handling the electrolytic cell? Ensure Safe and Accurate Lab Results