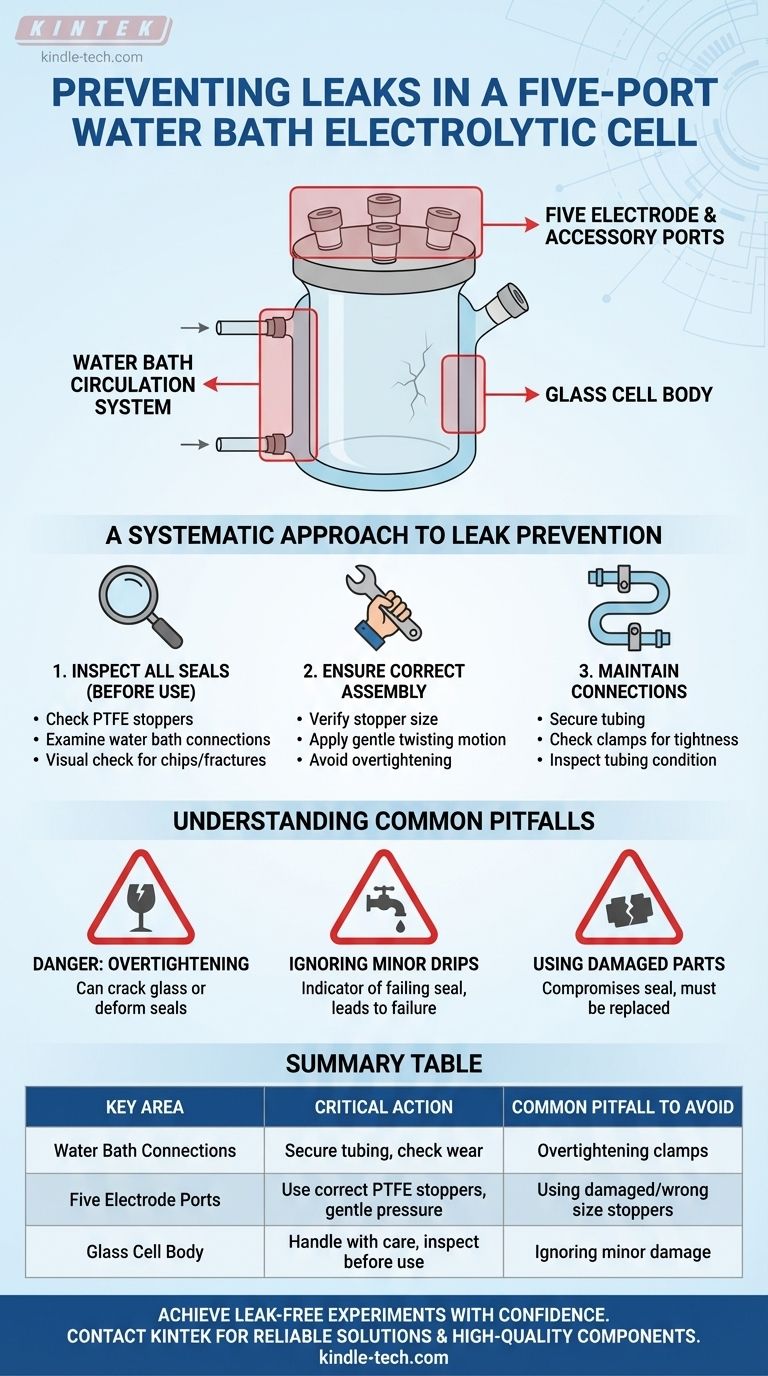

To prevent leaks in a five-port water bath electrolytic cell, you must focus on three critical areas: systematically inspecting all seals before use, ensuring proper assembly of all components, and handling the fragile glass cell with care. Leaks originate from the water bath circulation connections, the five main access ports, or a breach in the glass body itself, and vigilance in these areas is key to prevention.

The core challenge is not just stopping leaks, but maintaining a consistently reliable experimental environment. This is achieved by treating leak prevention as a systematic process of pre-use inspection and careful assembly, rather than a reaction to failure.

Pinpointing the Sources of Leaks

An electrolytic cell is a system of connections, and every connection is a potential point of failure. Understanding where leaks originate is the first step to preventing them.

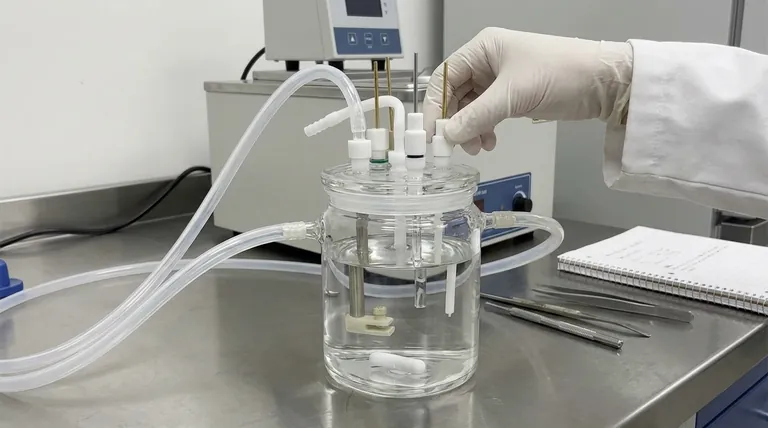

The Water Bath Circulation System

The two ports for the water jacket are a common source of leaks. These connections, where tubing is attached to circulate temperature-controlled water, are under constant mechanical stress. Seals here must be secure to prevent water from dripping onto your equipment.

The Five Electrode and Accessory Ports

Each of the five ports on the cell lid is sealed with a stopper, typically made of PTFE (Teflon). These ports house your working, auxiliary, and reference electrodes, as well as a gas inlet tube or Luggin capillary. A leak at any of these points can compromise your electrolyte volume and concentration.

The Glass Cell Body Itself

The electrolytic cell is made of glass, which is inherently fragile. A hairline crack or a chip at the edge of a port, often caused by improper handling or overtightening, will create an unfixable leak. Careful handling is a primary form of leak prevention.

A Systematic Approach to Leak Prevention

Adopt a routine of inspection and proper assembly before every experiment to ensure a sealed, stable environment.

Before Every Use: Inspect All Seals

Regularly inspect every sealing component. Check the PTFE stoppers for discoloration, warping, or cracks. Examine the connection points on the water bath inlet and outlet for any signs of wear. A visual check of the glass cell for any new chips or fractures is also essential.

Ensure Correct Component Fit and Assembly

Verify that you are using the correctly sized stopper for each port. The standard configuration often includes specific ports for items like a Luggin capillary. When inserting an electrode or stopper, apply gentle, even pressure with a slight twisting motion to ensure a snug fit without stressing the glass.

Maintain the Water Jacket Connections

Ensure the tubing for the water circulator is pushed securely onto the glass inlet and outlet ports. If clamps are used, they should be firm but not so tight that they risk cracking the glass. Periodically check the tubing itself for brittleness or cracks, especially near the connection points.

Understanding the Common Pitfalls

Avoiding common mistakes is as important as following correct procedures. Being aware of these pitfalls will help you maintain the integrity of your cell.

The Danger of Overtightening

When a small leak is detected, the first instinct is often to tighten the component further. This is a critical mistake. Overtightening a stopper or clamp can crack the fragile glass cell or permanently deform the PTFE seal, making the leak worse. Seals are designed to work with snug pressure, not brute force.

Ignoring Minor Drips

A small, occasional drip from a water bath connection is not a minor inconvenience; it is a clear indicator that a seal is failing. Ignoring it can lead to sudden, catastrophic failure, damage to sensitive electronics below, or safety hazards from hot water.

Using Damaged or Incorrect Parts

Never attempt to use a chipped Luggin capillary, a cracked electrode, or a stopper that is not designed for the port. A compromised component cannot create a reliable seal. If a part is damaged, it must be replaced.

Making the Right Choice for Your Goal

Your approach to leak prevention should align with your immediate objective.

- If your primary focus is routine experimental reliability: Implement a non-negotiable pre-use checklist to inspect every seal and connection point before introducing any liquids.

- If your primary focus is setting up a new cell for the first time: Carefully verify that all included components, like stoppers and aeration tubes, are undamaged and correctly matched to their designated ports.

- If your primary focus is troubleshooting an existing leak: Systematically isolate the source by starting with the most common failure points—the water jacket connections and electrode stoppers—before assuming a more serious issue like a crack in the cell body.

This diligent, systematic approach transforms leak prevention from a chore into a practice that ensures the safety, accuracy, and reliability of your electrochemical work.

Summary Table:

| Key Area | Critical Action | Common Pitfall to Avoid |

|---|---|---|

| Water Bath Connections | Securely attach tubing; check for wear. | Overtightening clamps, which can crack the glass. |

| Five Electrode Ports | Use correct PTFE stoppers; apply gentle, even pressure. | Using damaged or incorrect-sized stoppers. |

| Glass Cell Body | Handle with care; inspect for chips or cracks before use. | Ignoring minor damage that can lead to catastrophic failure. |

Achieve Leak-Free Electrochemical Experiments with Confidence

Preventing leaks is crucial for the safety and accuracy of your work. At KINTEK, we understand the importance of reliable lab equipment. We specialize in high-quality laboratory glassware, including electrolytic cells, and the consumables needed to maintain them.

Let us support your research:

- Durable Equipment: Source robust electrolytic cells designed for long-term use.

- Precision Consumables: Ensure a perfect seal with high-quality PTFE stoppers and components.

Don't let leaks compromise your data. Contact our experts today to find the right solutions for your laboratory's specific needs and ensure the integrity of your electrochemical setups.

Visual Guide

Related Products

- Electrolytic Electrochemical Cell with Five-Port

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

People Also Ask

- How should the body of an electrolytic cell be maintained for longevity? Extend Your Equipment's Lifespan

- How should the five-port water bath electrolytic cell be operated during an experiment? Master Precise Control for Reliable Results

- How can contamination be avoided during experiments with the five-port water bath electrolytic cell? Master the 3-Pillar Protocol

- What general precaution should be taken when handling the electrolytic cell? Ensure Safe and Accurate Lab Results

- What is the proper way to handle a five-port water bath electrolytic cell? Ensure Accurate and Safe Electrochemical Experiments