To ensure the longevity of an electrolytic cell body, you must adopt a disciplined maintenance routine centered on four key actions: cleaning it immediately after each use, regularly inspecting it for damage, handling it with care, and storing it in a clean, dry environment. This prevents chemical corrosion, physical breakage, and moisture-related degradation, preserving the integrity of the apparatus for reliable and repeatable experiments.

The core principle of cell body maintenance is not just about extending its physical life, but about safeguarding the integrity of your entire electrochemical system. Proactive care prevents minor issues from escalating into catastrophic failures that compromise data, safety, and equipment.

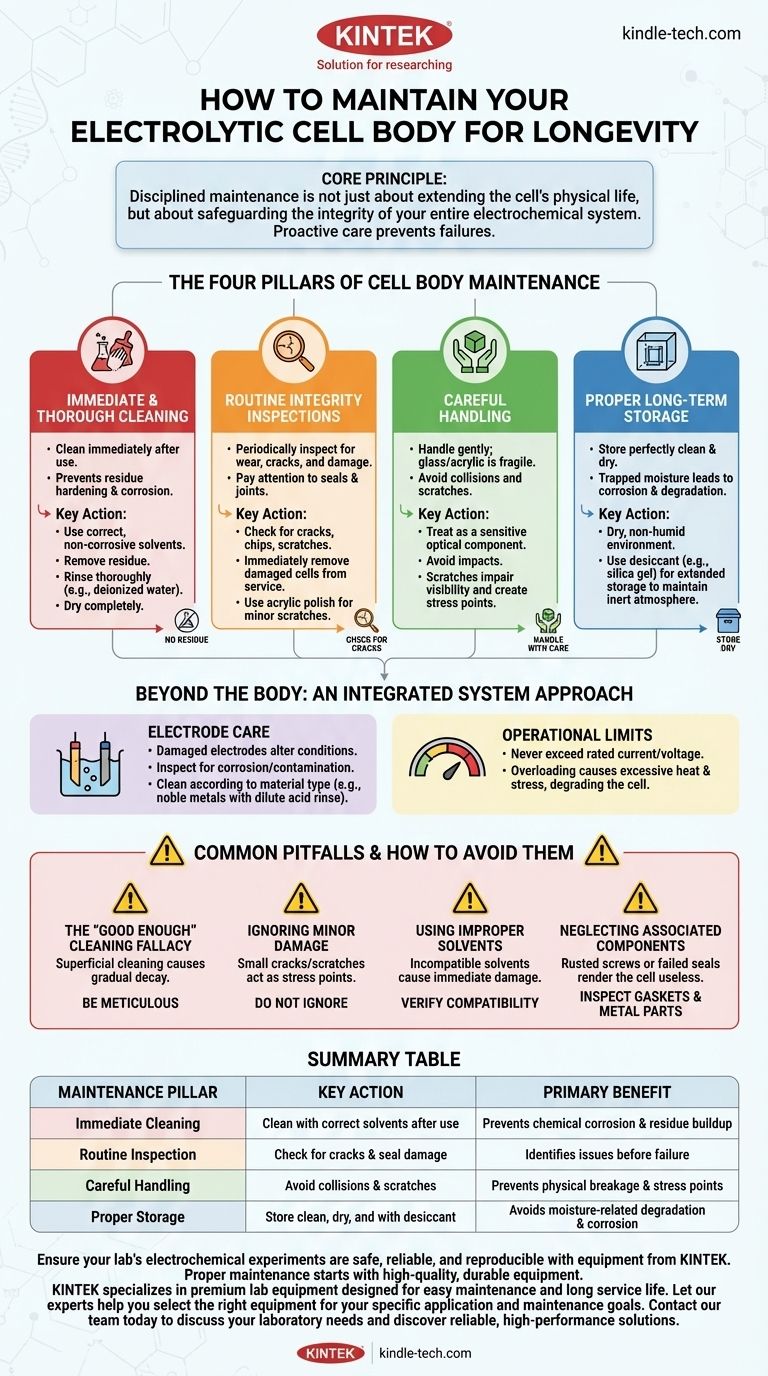

The Four Pillars of Cell Body Maintenance

Effective maintenance is built on a foundation of consistent, simple actions. Integrating these four pillars into your standard operating procedure is the most effective way to maximize the life of your equipment.

Pillar 1: Immediate and Thorough Cleaning

Cleaning the cell body and electrodes immediately after an experiment is the single most important step you can take. This prevents residual chemicals and reaction byproducts from hardening or causing corrosion.

Use appropriate, non-corrosive solvents to clean all surfaces. Ensure you remove any residue from the reaction vessel and rinse thoroughly, typically with deionized water, before drying.

Pillar 2: Routine Integrity Inspections

Periodically inspect the cell body for any signs of wear, damage, or aging. Look for cracks, chips, and scratches, paying close attention to seals and joints.

If you find any significant cracks or damage, the cell must be taken out of service immediately to prevent leaks or failure during operation. For minor scratches on acrylic cells, an acrylic-specific polishing agent can sometimes be used.

Pillar 3: Careful Handling

Electrolytic cells are often constructed from glass or acrylic, which are fragile materials. Always handle the cell gently to avoid collisions with hard objects that can cause cracks or breakage.

The low surface hardness of acrylic also makes it prone to scratching, which can impair visibility and create stress points. Treat it with the same care you would any sensitive optical component.

Pillar 4: Proper Long-Term Storage

For storage, the cell must be perfectly clean and completely dry. Any trapped moisture can lead to corrosion of metal components or degradation of the cell body itself over time.

Store the cell and its components in a dry, non-humid environment. For extended storage, placing a desiccant like silica gel inside the clean, dry cell can help maintain an inert internal atmosphere.

Beyond the Body: An Integrated System Approach

The health of the cell body is directly linked to the condition and operation of the entire system. A holistic view is essential for true longevity.

The Critical Role of Electrode Care

Damaged or contaminated electrodes can alter experimental conditions, sometimes leading to unintended side reactions that could harm the cell body. Regularly inspect electrodes for corrosion or contamination.

Clean electrodes according to their material type. For example, noble metals like platinum can often be cleaned by soaking in a dilute acid, followed by a thorough rinse with deionized water.

Adhering to Operational Limits

Never exceed the rated current and voltage for your electrolytic cell. Overloading the system creates excessive heat and physical stress that can degrade or damage the cell body, seals, and electrodes over time.

Common Pitfalls and How to Avoid Them

Even with good intentions, common oversights can shorten a cell's lifespan. Awareness of these pitfalls is key to avoiding them.

The "Good Enough" Cleaning Fallacy

Superficial cleaning is a primary cause of gradual decay. Invisible chemical residues can slowly etch surfaces or corrode seals, leading to premature failure. Always be meticulous.

Ignoring Minor Damage

A small scratch or hairline crack can seem insignificant, but it acts as a stress concentration point. Under thermal or physical stress during an experiment, this minor flaw can propagate, causing a catastrophic failure.

Using Improper Solvents

Using a cleaning solvent that is incompatible with the cell material can cause immediate and irreversible damage. For example, harsh organic solvents can cause acrylic to cloud or craze. Always verify solvent compatibility.

Neglecting Associated Components

A pristine glass or acrylic body is useless if its screws are rusted shut or its seals have failed. Ensure all metal parts are kept dry to prevent rust and inspect all gaskets and seals as part of your routine check.

Making the Right Choice for Your Goal

Your maintenance priority may shift slightly depending on your primary objective.

- If your primary focus is experimental accuracy: Prioritize immediate, meticulous cleaning after every single use to eliminate any risk of cross-contamination.

- If your primary focus is long-term asset preservation: Implement a strict dry-storage protocol, ensuring the cell and its components are perfectly dry and stored with a desiccant.

- If your primary focus is operational safety: Make routine inspection for cracks and seal integrity your non-negotiable top priority and immediately retire any damaged equipment.

Ultimately, disciplined and consistent maintenance is the foundation that underpins safe, reliable, and reproducible scientific work.

Summary Table:

| Maintenance Pillar | Key Action | Primary Benefit |

|---|---|---|

| Immediate Cleaning | Clean with correct solvents after each use. | Prevents chemical corrosion and residue buildup. |

| Routine Inspection | Check for cracks, chips, and seal damage. | Identifies issues before they cause failure. |

| Careful Handling | Avoid collisions and scratches. | Prevents physical breakage and stress points. |

| Proper Storage | Store clean, dry, and with desiccant. | Avoids moisture-related degradation and corrosion. |

Ensure your lab's electrochemical experiments are safe, reliable, and reproducible with equipment from KINTEK.

Proper maintenance is key to longevity, but it starts with high-quality, durable equipment. KINTEK specializes in premium lab equipment and consumables, including electrolytic cells designed for easy maintenance and long service life. Our products help you achieve accurate results while protecting your investment.

Let our experts help you select the right equipment for your specific application and maintenance goals. Contact our team today to discuss your laboratory needs and discover how KINTEK can support your research with reliable, high-performance solutions.

Visual Guide

Related Products

- Electrolytic Electrochemical Cell with Five-Port

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- Electrolytic Electrochemical Cell for Coating Evaluation

- H Type Electrolytic Cell Triple Electrochemical Cell

People Also Ask

- What material is the five-port water bath electrolytic cell made of? High Borosilicate Glass & PTFE Explained

- How can leaks be prevented when using a five-port water bath electrolytic cell? Ensure a Reliable and Safe Electrochemical Setup

- How should the five-port water bath electrolytic cell be operated during an experiment? Master Precise Control for Reliable Results

- How can contamination be avoided during experiments with the five-port water bath electrolytic cell? Master the 3-Pillar Protocol

- What is the proper way to handle a five-port water bath electrolytic cell? Ensure Accurate and Safe Electrochemical Experiments