To prevent contamination in a five-port water bath electrolytic cell, you must adopt a systematic approach that includes controlling the external environment, meticulously cleaning each component according to its material, and ensuring a perfect seal at all ports during assembly. This protocol is essential for maintaining the purity of your electrolyte and achieving accurate, reproducible results.

The core challenge is not just cleaning the cell, but treating the entire setup as a controlled system. Every port, every tube, and even the surrounding air is a potential vector for contaminants that can invalidate your electrochemical measurements.

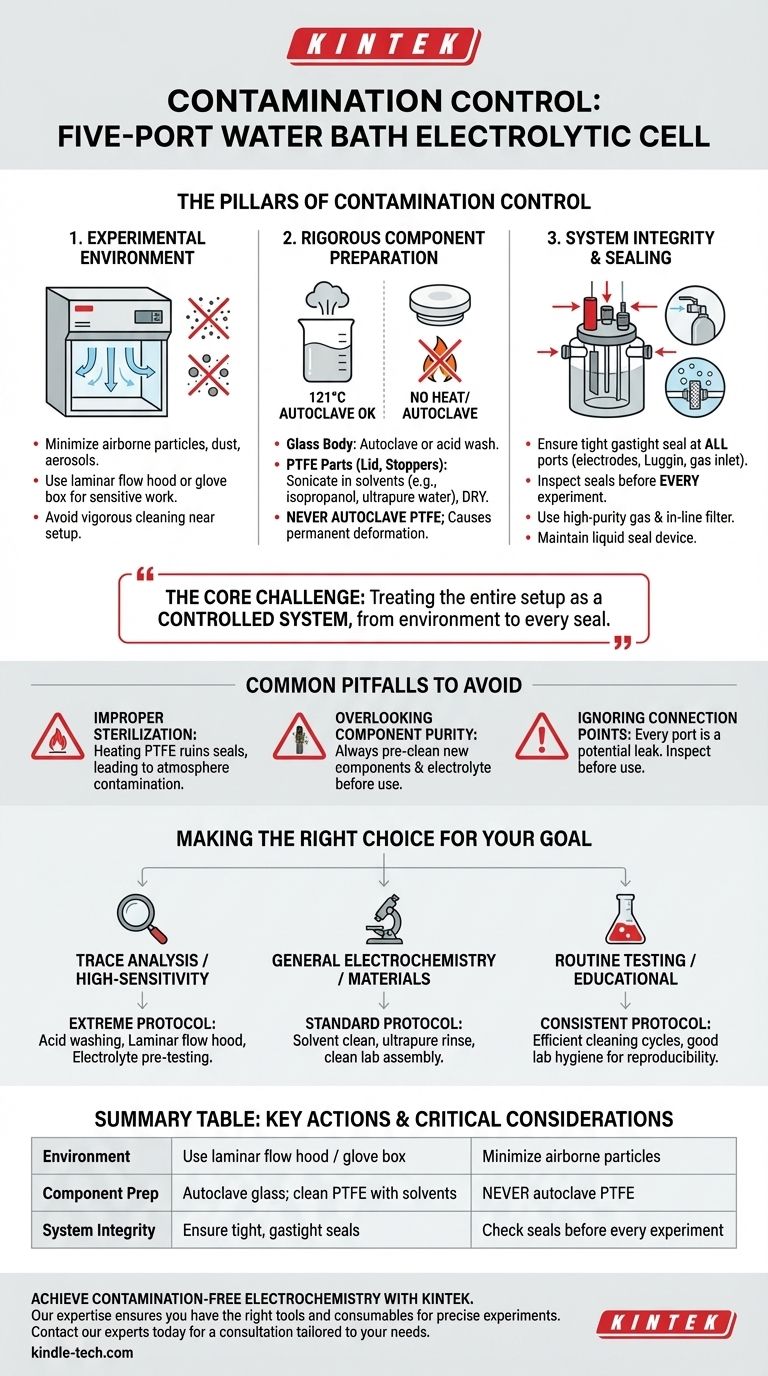

The Pillars of Contamination Control

Achieving a contamination-free experiment relies on three distinct areas of focus: the environment, the components themselves, and the integrity of the assembled system.

Pillar 1: The Experimental Environment

Your experiment is vulnerable to the conditions of the room it is in. The first line of defense is to manage the surrounding area.

Minimize airborne particles by avoiding any operations that generate dust, aerosols, or other pollutants near the electrolytic cell. This includes tasks like weighing powders or vigorous cleaning activities.

For highly sensitive experiments, consider performing the assembly and operation inside a laminar flow hood or a glove box to create a controlled, particle-free atmosphere.

Pillar 2: Rigorous Component Preparation

Each part of the cell requires a specific cleaning protocol. A one-size-fits-all approach will fail and may even damage the equipment.

The glass cell body can and should be thoroughly cleaned. For biological or organic-sensitive work, it can be sterilized by autoclaving at 121°C.

The Polytetrafluoroethylene (PTFE) components, such as the lid and stoppers, must never be autoclaved or heated. High temperatures will cause the PTFE to expand and deform permanently, compromising the seal of the cell.

Clean PTFE parts by sonicating them in appropriate solvents (e.g., isopropanol, ultrapure water) and allowing them to dry in a clean environment.

Pillar 3: System Integrity and Sealing

A clean cell is useless if it is not sealed properly. Each port is a potential entry point for contamination from the outside air.

Ensure all PTFE stoppers create a tight fit in their respective ports. The standard configuration often includes two 6.2mm electrode ports and a port for the Luggin capillary, all of which must be securely sealed.

If using a gas inlet device for sparging or blanketing the electrolyte, use a high-purity gas source and consider adding an in-line filter to remove any particulate matter from the gas stream.

The liquid seal device is critical for preventing gas exchange with the atmosphere while maintaining pressure equilibrium. Ensure it is filled with a suitable, clean liquid and is functioning correctly.

Common Pitfalls to Avoid

Mistakes in handling and preparation are the most common source of contamination. Being aware of these pitfalls is critical for consistent success.

Improper Sterilization

The single most critical mistake is heating the entire cell assembly. Autoclaving the PTFE lid will destroy its precise fit, rendering it unable to properly seal the cell. This will inevitably lead to contamination from the atmosphere.

Overlooking Component Purity

Never assume that new components, including electrodes, aeration tubes, or even the electrolyte itself, are perfectly clean. Always pre-clean all parts according to a validated protocol before their first use.

Ignoring Connection Points

Every connection—from the reference electrode in its Luggin capillary to the working electrode port—is a potential leak point. Inspect all seals before every experiment to ensure a gastight and liquid-tight system.

Making the Right Choice for Your Goal

Your cleaning and handling protocol should match the sensitivity of your experiment.

- If your primary focus is trace analysis or high-sensitivity measurements: Your protocol must be extreme, likely involving acid washing of glassware, use of a laminar flow hood, and pre-testing your electrolyte for background signals.

- If your primary focus is general electrochemistry or material characterization: A standard protocol of solvent cleaning, thorough rinsing with ultrapure water, and careful assembly in a clean lab space is typically sufficient.

- If your primary focus is routine testing or educational purposes: Focus on consistent and efficient cleaning cycles and good lab hygiene to ensure reproducibility between runs, even if absolute purity is not the highest priority.

By mastering these protocols, you transform your electrolytic cell from a simple piece of glassware into a reliable instrument for precise scientific inquiry.

Summary Table:

| Contamination Control Pillar | Key Action | Critical Consideration |

|---|---|---|

| Experimental Environment | Use a laminar flow hood or glove box. | Minimize airborne particles and dust. |

| Component Preparation | Clean glass with autoclave; clean PTFE with solvents. | NEVER autoclave PTFE components. |

| System Integrity & Sealing | Ensure all ports and stoppers create a tight, gastight seal. | Check seals before every experiment. |

Achieve contamination-free electrochemistry with KINTEK.

Our expertise in laboratory equipment ensures you have the right tools and consumables for precise experiments. From high-purity solvents for cleaning to durable PTFE components, we support your research integrity.

Let us help you optimize your setup. Contact our experts today for a consultation tailored to your specific electrochemical needs.

Visual Guide

Related Products

- Electrolytic Electrochemical Cell with Five-Port

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- PTFE Electrolytic Cell Electrochemical Cell Corrosion-Resistant Sealed and Non-Sealed

People Also Ask

- What is the H type photoelectrochemical cell? A Guide to Isolating & Studying Light-Driven Reactions

- What are the advantages of using laboratory electrolytic hydrogen charging equipment? Speed & Control for HIC Studies

- How does a three-electrode electrochemical cell configuration ensure accurate 904L stainless steel corrosion measurement?

- What materials are used for the body of a super-sealed electrolytic cell and what are their properties? Select the Right Material for Your Experiment

- How should the experimental parameters be adjusted when using the H-type electrolytic cell? Expert Precision Guide

- What parameters and phenomena should be monitored during an experiment using the electrolytic cell? Ensure Safe and Efficient Electrolysis

- How should an all-PTFE electrolytic cell be stored after use? Expert Maintenance Tips for Long-Lasting Performance

- How does an electrolytic polishing and etching unit assist in revealing grain boundaries? High-Res Alloy Analysis