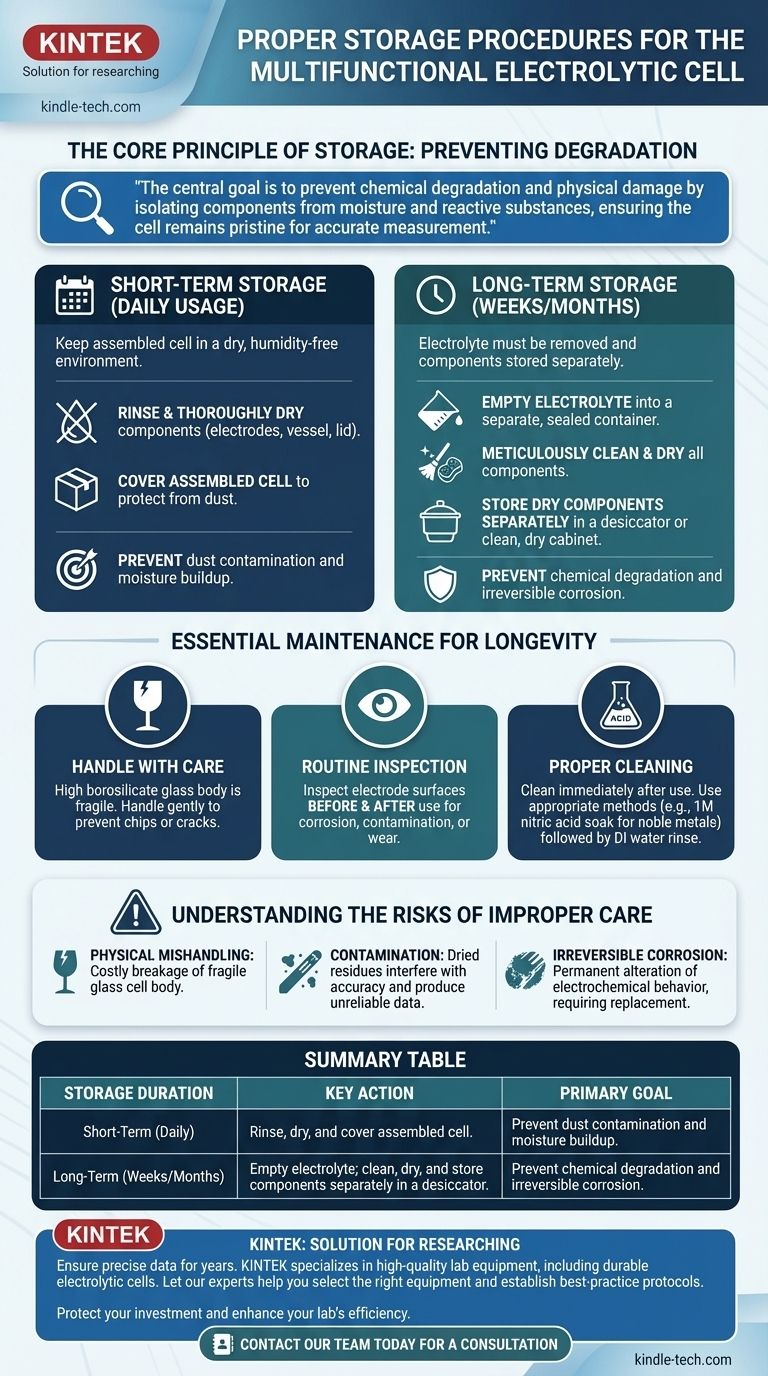

To properly store your multifunctional electrolytic cell, you must ensure all components, especially the electrodes and reaction vessel, are thoroughly cleaned and completely dry. For short-term storage, keep the assembled cell in a dry, humidity-free environment. For long-term storage, the electrolyte must be poured out and stored in a separate, sealed container before placing the dry cell components in storage.

The central goal of proper storage is to prevent chemical degradation and physical damage. This is achieved by isolating components from moisture and reactive substances, ensuring the cell remains pristine and ready for the next accurate measurement.

The Core Principle of Storage: Preventing Degradation

Proper storage is not just about putting the cell away; it's an active process to preserve the integrity of its sensitive components. The two primary enemies of an electrolytic cell in storage are moisture and residual chemicals.

Why Dryness is Critical

Moisture is the catalyst for corrosion and unwanted electrochemical reactions. Even trace amounts of water left on an electrode's surface can lead to oxidation, altering its properties and compromising future experimental results. A dry environment prevents this slow degradation.

Separating the Electrolyte for Long-Term Storage

Leaving the electrolyte in the cell for extended periods is a significant risk. Slow, unwanted reactions can continue to occur at the electrode surfaces, causing corrosion or plating that is difficult to reverse. It can also lead to the contamination of your electrolyte solution.

Choosing the Right Storage Environment

The ideal storage location is a clean, dry cabinet or desiccator, away from dust and corrosive chemical vapors. This ensures that no external contaminants can settle on the sensitive electrode surfaces or the glass vessel.

Beyond Storage: Essential Maintenance for Longevity

A disciplined maintenance routine is as important as the storage procedure itself. The longevity and accuracy of your cell depend on how it is handled and cared for between uses.

Handle with Extreme Care

The body of the cell is typically made of high borosilicate glass, which is fragile. Always handle it gently to prevent chips or cracks. The lid is often a durable material like PTFE, but the glass components demand careful manipulation at all times.

The Importance of Routine Inspection

Before and after each use, visually inspect the electrode surfaces. Look for signs of corrosion, contamination, physical damage, or wear. Early detection of a problem can save an electrode from irreversible damage.

Proper Cleaning Procedures

Always clean the cell components immediately after use. A common practice for noble metal electrodes (e.g., platinum) is a soak in a dilute acid, such as 1M nitric acid, followed by a thorough rinse with deionized water. This removes reaction byproducts and surface contaminants.

Preventing Electrode Oxidation

Some metal electrodes are highly susceptible to oxidation when exposed to air. For these specific electrodes, storage may involve immersion in a dedicated protective solution or placement within a dry, oxygen-free environment like a nitrogen-filled glovebox.

Understanding the Risks of Improper Care

Failing to follow proper procedures introduces significant risks that can be costly in terms of both time and equipment.

The Danger of Physical Mishandling

The most immediate and costly mistake is breaking the glass cell body. This is entirely preventable with careful, deliberate handling. A broken cell means project delays and replacement costs.

The Consequence of Contamination

Storing the cell without proper cleaning allows residues to dry onto the electrode surfaces. This contamination can be difficult to remove and will interfere with the accuracy of your next experiment, producing unreliable data.

The Irreversibility of Corrosion

Once an electrode's surface is significantly corroded or pitted due to improper storage, its electrochemical behavior is permanently altered. In many cases, the electrode cannot be salvaged and must be replaced.

How to Apply This to Your Protocol

Your storage procedure should adapt based on how long the cell will be inactive.

- If your primary focus is short-term storage (between daily experiments): Your priority is to rinse all components with deionized water, ensure they are thoroughly dry, and cover the cell to protect it from dust.

- If your primary focus is long-term storage (weeks or months): You must empty the electrolyte, clean and dry all components meticulously, and store the dry cell and the electrolyte in separate, sealed containers in a desiccator.

- If your primary focus is maximizing electrode lifespan: Implement a strict protocol of post-use inspection and cleaning, using appropriate chemical methods for your specific electrode materials.

Following a disciplined storage and maintenance protocol is the most effective way to protect your investment and ensure the continued reliability of your experimental results.

Summary Table:

| Storage Duration | Key Action | Primary Goal |

|---|---|---|

| Short-Term (Daily) | Rinse, dry, and cover assembled cell. | Prevent dust contamination and moisture buildup. |

| Long-Term (Weeks/Months) | Empty electrolyte; clean, dry, and store components separately in a desiccator. | Prevent chemical degradation and irreversible corrosion. |

Ensure your lab's electrolytic cells deliver precise, reliable data for years to come. Proper storage is critical, but having the right equipment is the first step. KINTEK specializes in high-quality lab equipment and consumables, including durable electrolytic cells made with materials like high borosilicate glass and PTFE. Our experts can help you select the right equipment and establish best-practice protocols for maintenance and storage. Protect your investment and enhance your lab's efficiency – contact our team today for a consultation.

Visual Guide

Related Products

- Electrolytic Electrochemical Cell with Five-Port

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- H Type Electrolytic Cell Triple Electrochemical Cell

- Electrolytic Electrochemical Cell for Coating Evaluation

People Also Ask

- How can leaks be prevented when using a five-port water bath electrolytic cell? Ensure a Reliable and Safe Electrochemical Setup

- How should the five-port water bath electrolytic cell be operated during an experiment? Master Precise Control for Reliable Results

- How should the five-port water bath electrolytic cell be cleaned for maintenance? A Step-by-Step Guide to Reliable Results

- What material is the five-port water bath electrolytic cell made of? High Borosilicate Glass & PTFE Explained

- What is the proper way to handle a five-port water bath electrolytic cell? Ensure Accurate and Safe Electrochemical Experiments