Above all, an electrolytic cell must be handled gently. Because the cell body is typically made of fragile glass or quartz, preventing breakage from physical shock is paramount. Additionally, when working with corrosive electrolytes, you must always use appropriate personal protective equipment (PPE) and work in a well-ventilated area like a fume hood.

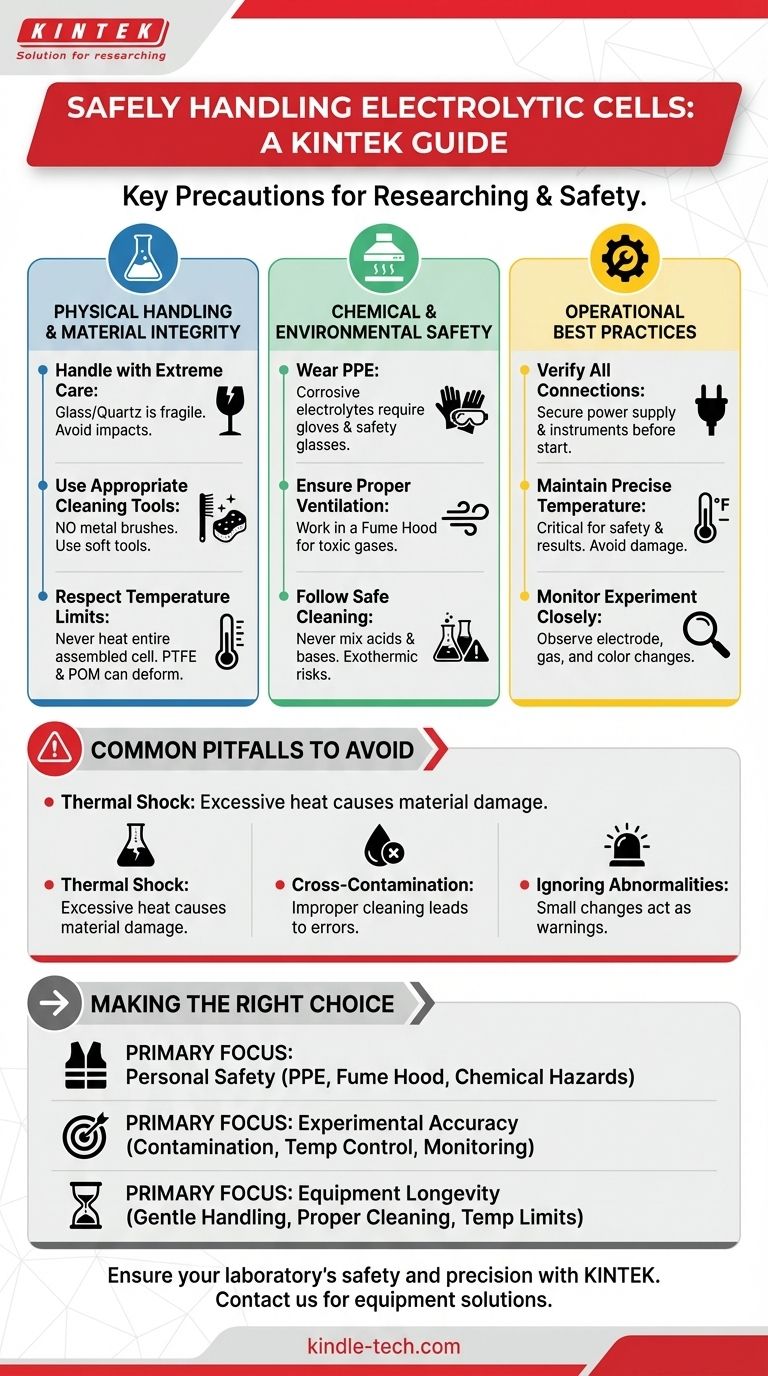

The safe and effective use of an electrolytic cell depends on three core principles: careful physical handling to protect its fragile materials, strict chemical safety protocols to protect yourself, and precise control of experimental parameters to ensure accurate results.

Physical Handling and Material Integrity

The physical structure of the cell is its most vulnerable aspect. Understanding the limits of its materials is the first step toward preventing damage and ensuring a long operational life.

Handle with Extreme Care

The cell body, whether made of glass or quartz, is brittle and susceptible to cracking or shattering from impact. Always handle it gently and avoid collisions with hard objects.

Use Appropriate Cleaning Tools

Never use metal brushes for cleaning. These can easily scratch the interior surfaces of the cell, which can compromise your experimental results and create stress points that lead to future breakage.

Respect Temperature Limitations

While the glass body can often be sterilized at 121°C, the complete assembly has different thermal limits. Materials like PTFE can expand permanently and POM can crack under high heat, so never heat the entire assembled cell unless specified.

Chemical and Environmental Safety

Beyond physical handling, managing the chemical environment is crucial for both personal safety and the validity of your experiment.

Wear Personal Protective Equipment (PPE)

When using corrosive electrolytes, protective gloves and safety glasses are non-negotiable. Direct contact can cause severe burns or injury.

Ensure Proper Ventilation

Many electrochemical reactions produce harmful gases. Always conduct your experiments in a fume hood to prevent the inhalation of toxic or corrosive vapors.

Follow Safe Cleaning Procedures

Never mix acids and bases (like nitric acid and sodium hydroxide) during the cleaning process. This can trigger a dangerous exothermic reaction, posing a significant safety risk.

Prevent Contamination

Maintain the purity of your electrolyte. Prevent any foreign impurities from entering the cell and protect the cell's surfaces from external contaminants to ensure the accuracy of your results.

Operational Best Practices

Correct procedure during the experiment itself is the final piece of the puzzle, ensuring both safety and reliable data.

Verify All Connections

Before starting, ensure the electrolytic cell is correctly connected to its power supply and detection instruments. Set your experimental parameters carefully according to your established procedure.

Maintain Precise Temperature Control

If using a constant temperature water bath, precise and stable temperature control is critical. Temperatures that are too high or too low can negatively affect results and even damage the cell or create safety hazards like burns.

Monitor the Experiment Closely

Actively observe the process. Pay close attention to changes on the electrode surface, any gas generation, or shifts in solution color. Addressing any abnormalities immediately is key to a successful experiment.

Common Pitfalls to Avoid

Mistakes often happen when an operator overlooks the interplay between the cell's materials and the experimental conditions.

Thermal Shock and Material Damage

A common error is exposing the assembled cell to excessive heat. This can cause differential expansion between the glass, PTFE, and POM components, leading to irreparable damage. Always know the thermal limits of every part of your assembly.

Cross-Contamination from Improper Cleaning

Failing to clean the cell thoroughly or using inappropriate tools can leave residue that contaminates future experiments. This invalidates results and can cause unintended and potentially hazardous side reactions.

Ignoring In-Process Abnormalities

Small, unexpected changes during an experiment are often early warnings. Ignoring a sudden color change or unexpected gas bubbling can lead to experimental failure or a safety incident. Vigilant observation is not optional.

Making the Right Choice for Your Goal

Your primary objective will determine which precautions demand the most attention.

- If your primary focus is personal safety: Prioritize wearing appropriate PPE, working within a fume hood, and understanding the chemical hazards of your electrolyte.

- If your primary focus is experimental accuracy: Emphasize preventing contamination, ensuring precise temperature control, and correctly monitoring all parameters.

- If your primary focus is equipment longevity: Concentrate on gentle handling to prevent breakage, using proper cleaning tools, and respecting the material temperature limits.

Ultimately, disciplined adherence to established procedures is the key to safe, repeatable, and successful work with any electrolytic cell.

Summary Table:

| Precaution Category | Key Actions | Primary Goal |

|---|---|---|

| Physical Handling | Handle gently, avoid metal brushes, respect temperature limits. | Equipment Longevity |

| Chemical Safety | Wear PPE, use fume hood, follow safe cleaning procedures. | Personal Safety |

| Operational Practice | Verify connections, control temperature, monitor experiment closely. | Experimental Accuracy |

Ensure your laboratory's safety and precision with equipment you can trust. The correct handling of sensitive instruments like electrolytic cells is fundamental to achieving reliable results. At KINTEK, we specialize in providing high-quality lab equipment and consumables designed for durability and accuracy, serving the precise needs of laboratories.

Let our experts help you select the right equipment for your specific applications. Contact us today to discuss your lab's requirements and discover how we can support your research and safety goals.

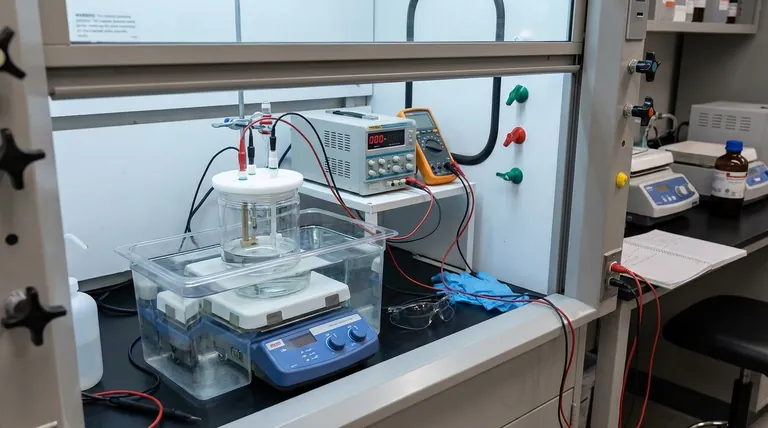

Visual Guide

Related Products

- Electrolytic Electrochemical Cell with Five-Port

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- H Type Electrolytic Cell Triple Electrochemical Cell

- Electrolytic Electrochemical Cell for Coating Evaluation

People Also Ask

- How should the body of an electrolytic cell be maintained for longevity? Extend Your Equipment's Lifespan

- How can leaks be prevented when using a five-port water bath electrolytic cell? Ensure a Reliable and Safe Electrochemical Setup

- What is the proper way to handle a five-port water bath electrolytic cell? Ensure Accurate and Safe Electrochemical Experiments

- What material is the five-port water bath electrolytic cell made of? High Borosilicate Glass & PTFE Explained

- What are the standard components of the five-port water bath electrolytic cell? Master the Precision Instrument for Electrochemical Analysis