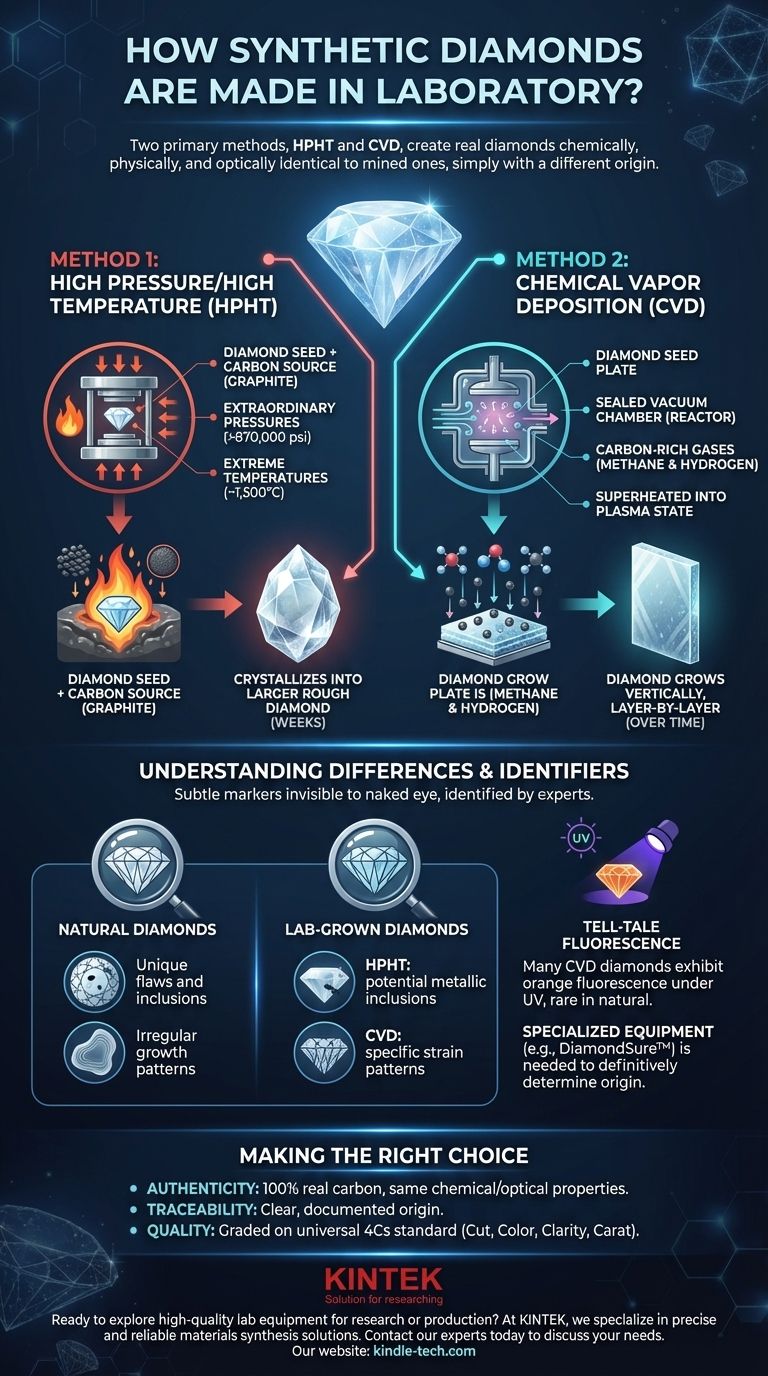

In a laboratory, diamonds are made using one of two primary methods. These are High Pressure/High Temperature (HPHT) and Chemical Vapor Deposition (CVD). Both processes create diamonds that are chemically, physically, and optically identical to those mined from the Earth; they are real diamonds, simply with a different origin.

The core principle of lab diamond creation is not imitation, but replication. One method, HPHT, recreates the intense pressure cooker environment of the Earth's mantle, while the other, CVD, "grows" a diamond atom by atom from a carbon gas.

The Two Pillars of Diamond Synthesis

To understand lab-grown diamonds, you must understand the two dominant and commercially viable production methods. While other techniques exist for creating industrial nanodiamonds, HPHT and CVD are the processes that produce the gem-quality stones used in jewelry.

Method 1: High Pressure/High Temperature (HPHT)

The HPHT method is the original process for diamond synthesis, designed to directly mimic the natural formation conditions deep within the Earth.

A small, natural diamond fragment, known as a diamond seed, is placed into a chamber with a pure carbon source, such as graphite.

This chamber is then subjected to extraordinary pressures (over 870,000 pounds per square inch) and extreme temperatures (around 1,500°C or 2,730°F).

At this point, the carbon source melts and crystallizes around the diamond seed, atom by atom, growing into a larger, rough diamond over several weeks.

Method 2: Chemical Vapor Deposition (CVD)

The CVD method takes a completely different approach, often described as building a diamond in layers. It requires lower pressures and temperatures than HPHT.

A thin diamond seed plate is placed inside a sealed vacuum chamber, also known as a reactor.

The chamber is filled with carbon-rich gases, typically methane and hydrogen, which are then superheated into a plasma state.

This process breaks the gas molecules apart, allowing pure carbon atoms to rain down and deposit onto the diamond seed plate, growing the diamond vertically over time.

Understanding the Differences and Identifiers

While lab-grown diamonds are chemically identical to their natural counterparts, the distinct growth processes leave behind subtle markers that are invisible to the naked eye but can be identified by gemological experts.

Growth Patterns and Inclusions

Natural diamonds form in a chaotic, uncontrolled environment, resulting in unique flaws and inclusions. The growth patterns are often irregular.

HPHT diamonds can sometimes contain tiny metallic inclusions from the manufacturing equipment. CVD diamonds, grown in layers, can exhibit specific strain patterns that differ from natural stones.

Tell-Tale Fluorescence

A key identifier is how the diamond reacts to ultraviolet (UV) light. Many CVD-grown diamonds exhibit a distinct orange fluorescence when exposed to UV radiation, a trait that is extremely rare in natural diamonds.

The Need for Specialized Equipment

It is crucial to understand that these differences are not visible without advanced tools. Gemological labs use devices like the DiamondSure™ UV/visible spectrometer to analyze a diamond's light absorption and definitively determine its origin.

Making the Right Choice for Your Goal

Understanding the science behind lab-grown diamonds empowers you to see them not as alternatives, but as a technological achievement.

- If your primary focus is authenticity: Both HPHT and CVD produce diamonds that are 100% real carbon, sharing the exact same chemical and optical properties as mined diamonds.

- If your primary focus is traceability: The lab-grown process offers a clear, documented origin, unlike many natural stones whose history can be difficult to verify.

- If your primary focus is quality: The creation method is secondary to the final result. Both HPHT and CVD diamonds are graded on the same universal standard—the 4Cs of cut, color, clarity, and carat.

Ultimately, understanding these methods confirms that lab-grown diamonds are not imitations, but simply diamonds with a different origin story.

Summary Table:

| Method | Process Description | Key Conditions |

|---|---|---|

| HPHT (High Pressure/High Temperature) | Mimics Earth's mantle. A diamond seed is placed with a carbon source under extreme pressure and heat to grow a diamond. | Pressure: >870,000 psi Temperature: ~1,500°C |

| CVD (Chemical Vapor Deposition) | Grows a diamond atom-by-atom from a carbon-rich gas plasma onto a seed plate in a vacuum chamber. | Lower pressure than HPHT Uses Methane & Hydrogen gases |

Ready to explore high-quality lab equipment for your research or production needs?

At KINTEK, we specialize in providing the precise and reliable laboratory equipment and consumables essential for advanced material synthesis, including diamond growth. Whether you are in R&D or scaling up production, our expertise can help you achieve consistent, high-quality results.

Contact our experts today to discuss how our solutions can support your specific laboratory requirements and drive your projects forward.

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- CVD Diamond Domes for Industrial and Scientific Applications

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- What are the various types of Chemical Vapor Deposition (CVD)? Expert Guide to APCVD, PECVD, MOCVD & More

- What is the RF sputtering method? A Guide to Thin-Film Deposition for Insulating Materials

- What is physical Vapour deposition techniques? A Guide to Sputtering, Evaporation & More

- How are thin films created? A Guide to Deposition Methods for Your Application

- What role does a resistance heating furnace play in CVD tantalum coating? Master Thermal Precision in CVD Systems

- What are the technical advantages of using a cold-wall horizontal reactor for TiO2? Maximize Efficiency & Film Purity

- What substrate is used in CVD? The Foundation for High-Quality Thin Films

- What are the benefits of using dual-tube gas nozzles in LCVD? Maximize System Reliability and Film Quality Control