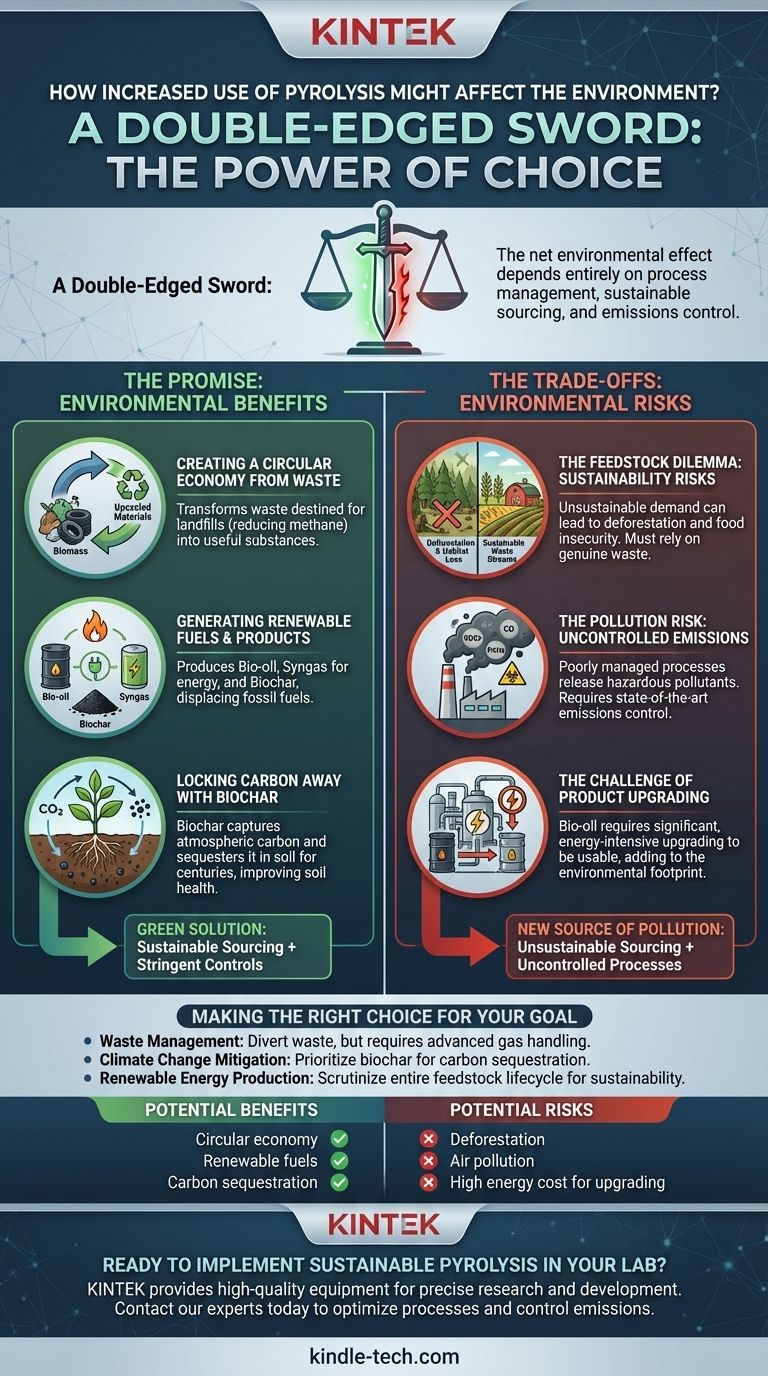

At its core, the environmental impact of increased pyrolysis is a double-edged sword. While it offers a powerful method for converting waste into valuable resources and reducing fossil fuel dependency, its net effect—positive or negative—is entirely dependent on how the process is managed, from the sourcing of materials to the control of emissions.

The ultimate environmental outcome of pyrolysis is not determined by the technology itself, but by human choices. Sustainable feedstock sourcing and stringent process controls are the deciding factors that separate a green solution from a new source of pollution.

The Promise: How Pyrolysis Can Benefit the Environment

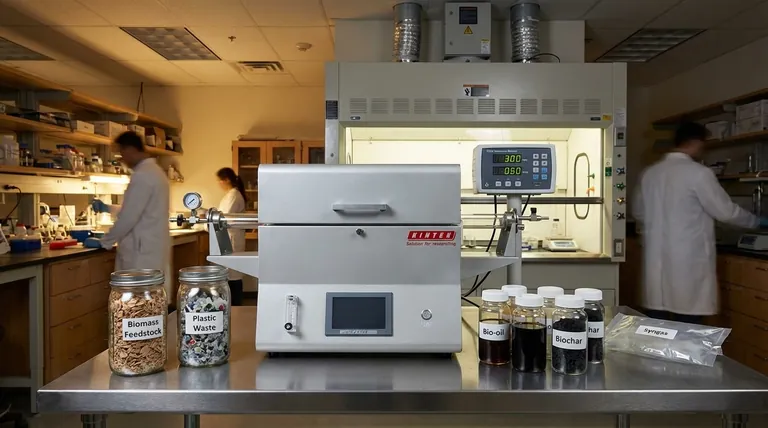

Pyrolysis is a process of thermal decomposition in the absence of oxygen. It can break down complex materials like biomass, plastics, and old tires into simpler, more valuable products.

Creating a Circular Economy from Waste

Pyrolysis is a key technology for a circular economy. It takes materials often destined for a landfill—which would generate methane, a potent greenhouse gas—and transforms them back into useful substances.

This process directly tackles the global waste crisis by offering a way to upcycle materials instead of simply disposing of them.

Generating Renewable Fuels and Products

The primary outputs of pyrolysis have significant environmental potential.

- Bio-oil: This liquid can be refined into transportation fuels or used to generate heat and electricity, displacing the need for fossil fuels.

- Syngas: This mixture of hydrogen and carbon monoxide is a combustible gas that can be used to power the pyrolysis facility itself or generate electricity.

- Biochar: This stable, carbon-rich solid has profound environmental benefits, particularly in carbon sequestration.

Locking Carbon Away with Biochar

When biomass is used as a feedstock, the resulting biochar effectively captures carbon that the plants originally absorbed from the atmosphere.

When added to soil, this biochar is highly resistant to decomposition. It can lock that carbon away for hundreds or even thousands of years, making it a powerful tool for carbon sequestration and mitigating climate change. Biochar also improves soil health and water retention.

Understanding the Trade-offs and Environmental Risks

The potential benefits of pyrolysis are matched by significant risks if the process is not implemented with rigorous environmental oversight. The promise can quickly sour if corners are cut.

The Feedstock Dilemma: Deforestation and Sustainability

The single greatest environmental risk comes from the source of the biomass. If demand for feedstock leads to the harvesting of virgin forests or the displacement of food crops, pyrolysis can cause deforestation, habitat loss, and food insecurity.

A truly sustainable pyrolysis operation must rely on genuine waste streams, such as agricultural residues, forestry by-products, or non-recyclable municipal solid waste.

The Pollution Risk: Uncontrolled Emissions

Pyrolysis is not combustion, but if the process is poorly designed or managed, harmful pollutants can be released into the atmosphere.

Leaks or incomplete processing can release volatile organic compounds (VOCs), carbon monoxide, and polycyclic aromatic hydrocarbons (PAHs), many of which are hazardous to human health and the environment. State-of-the-art emissions control and monitoring systems are non-negotiable.

The Challenge of Product Upgrading

Bio-oil is not a direct replacement for crude oil. It is often acidic, unstable, and contains high levels of oxygen and water, meaning it requires significant energy-intensive upgrading before it can be used in conventional refineries or engines.

The environmental footprint of this upgrading process must be factored into the total lifecycle assessment of any pyrolysis-to-fuel system.

Making the Right Choice for Your Goal

The decision to support or implement pyrolysis technology must be based on a clear understanding of its intended purpose and the systems in place to manage its risks.

- If your primary focus is waste management: Pyrolysis is a highly effective tool for diverting non-recyclable waste from landfills, but only if the facility employs advanced gas handling and emissions scrubbing technologies.

- If your primary focus is climate change mitigation: Prioritize processes that use waste biomass to produce biochar for carbon sequestration, as this offers the most direct and long-lasting climate benefit.

- If your primary focus is renewable energy production: You must scrutinize the feedstock's entire lifecycle to ensure it is genuinely sustainable and does not create negative unintended consequences like deforestation.

Ultimately, pyrolysis is a powerful technology whose environmental value is unlocked only through responsible and conscientious application.

Summary Table:

| Potential Benefits | Potential Risks |

|---|---|

| Creates a circular economy from waste | Risk of deforestation from unsustainable feedstock |

| Generates renewable fuels (bio-oil, syngas) | Air pollution from uncontrolled emissions (VOCs, PAHs) |

| Carbon sequestration via stable biochar | High energy cost for upgrading bio-oil into usable fuel |

Ready to implement sustainable pyrolysis technology in your lab?

KINTEK specializes in providing high-quality lab equipment and consumables for pyrolysis research and development. Our reliable solutions help you optimize processes, control emissions, and achieve your environmental goals—whether it's waste management, carbon sequestration, or renewable energy production.

Contact our experts today to discuss how we can support your laboratory's needs with precision equipment tailored for sustainable outcomes.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- Graphite Vacuum Continuous Graphitization Furnace

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- What is the primary advantage of using a tube furnace? Achieve Superior Temperature and Atmosphere Control

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance