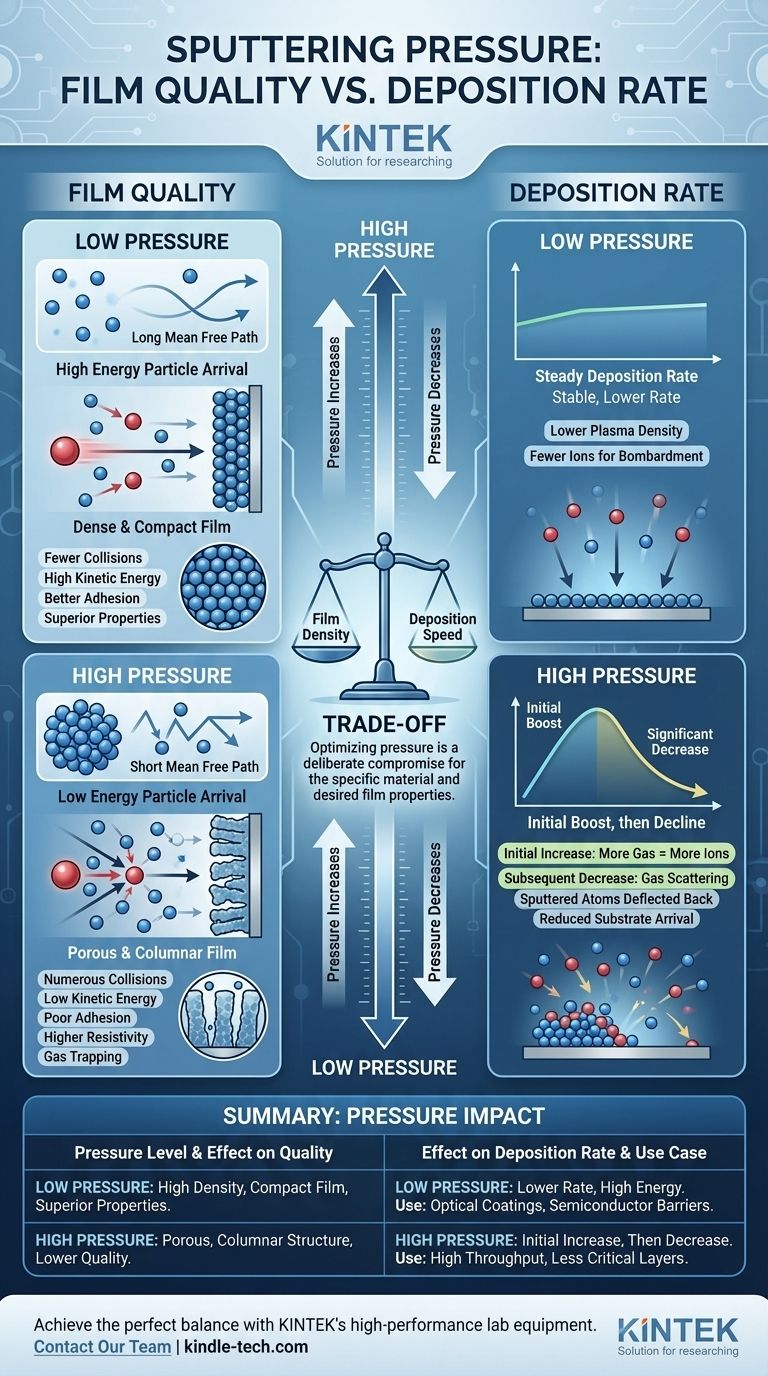

In sputtering, gas pressure is a fundamental control parameter with a direct and often competing influence on film quality and deposition rate. Generally, operating at a lower working pressure increases the energy of particles arriving at the substrate, which promotes the growth of dense, high-quality films. Conversely, increasing the pressure can initially boost the sputtering rate up to a point, but often at the cost of film quality due to increased particle collisions and energy loss.

The central challenge in setting your sputtering pressure is navigating the inherent trade-off between deposition speed and final film quality. There is no single "best" pressure; the optimal setting is a deliberate compromise tailored to the specific material being deposited and the desired properties of the final film.

The Physics: How Gas Pressure Governs the Process

To control the outcome, you must first understand the mechanism. Gas pressure is not just a number on a gauge; it fundamentally alters the environment between the sputtering target and your substrate.

Governing the Mean Free Path

The most critical concept is the mean free path: the average distance a particle (an ion or a sputtered atom) travels before colliding with a gas atom.

- At low pressure, there are fewer gas atoms, resulting in a long mean free path.

- At high pressure, there are many gas atoms, resulting in a short mean free path.

This single factor dictates the energy and direction of all particles in the chamber.

Determining Particle Energy

The energy with which sputtered atoms arrive at your substrate is paramount for film quality. Pressure is the primary knob for controlling this energy.

At low pressure, sputtered atoms undergo few or no collisions on their journey from the target. They arrive at the substrate with high kinetic energy, which is beneficial for forming dense films.

At high pressure, these same atoms suffer numerous collisions with the background gas. Each collision robs them of energy, causing them to arrive at the substrate with very low energy.

How Pressure Directly Impacts Film Quality

The energy of the arriving atoms directly translates into the microstructure and physical properties of the deposited film.

Low Pressure: Denser, Higher-Quality Films

When atoms arrive with high energy (due to low pressure), they have enough mobility to move across the substrate surface. This allows them to settle into energetically favorable sites in the film's lattice structure.

The result is a denser, more compact film with fewer voids or pinholes. This generally leads to better adhesion, superior optical or electrical properties, and higher internal integrity.

High Pressure: Porous, Lower-Quality Films

When atoms arrive with low energy (due to high pressure), they essentially "stick where they land." They lack the energy to rearrange themselves into an optimal structure.

This creates a more porous, columnar film structure with significant voids between grains. These films often exhibit poor adhesion, higher electrical resistivity, and can trap sputtering gas, leading to high internal stress and instability over time.

The Complicated Effect on Sputtering Rate

The relationship between pressure and deposition rate is not linear and can be misleading if not understood properly.

The Initial Rate Increase

Starting from a very low pressure, a slight increase in pressure provides more gas atoms (typically Argon) to be ionized. This increases the density of the plasma and the number of ions available to bombard the target, which in turn increases the rate at which material is sputtered from the target.

The Tipping Point and Rate Decrease

However, as pressure continues to rise, two negative effects begin to dominate.

First, the cloud of gas atoms near the target becomes so dense that it can scatter the bombarding ions, reducing the efficiency of the sputtering process itself.

Second, and more importantly, the sputtered atoms are increasingly scattered on their way to the substrate. They may be deflected back to the target or onto the chamber walls, never reaching your sample. This causes the actual deposition rate on the substrate to decrease significantly, even if material is still being removed from the target at a high rate.

Understanding the Trade-offs

Optimizing a sputtering process is an exercise in balancing competing factors. Pressure is at the heart of this challenge.

The Rate vs. Quality Dilemma

The core trade-off is clear: chasing the highest possible deposition rate by increasing pressure will almost always sacrifice film quality. The pressure that yields the fastest deposition is rarely the pressure that yields the densest, most functional film.

The Uniformity Factor

At very low pressures, deposition can become more "line-of-sight," which may reduce film thickness uniformity across large or complex-shaped substrates. A slightly higher pressure can use gas scattering to your advantage, creating a more diffuse flux of atoms that can coat surfaces more uniformly, though this comes at the cost of density.

Interaction with Power

Pressure does not act in isolation. As noted with RF sputtering, increasing power also increases ion bombardment energy. Therefore, a low-pressure process can sometimes be mimicked by a higher-pressure process with significantly more power, but this introduces its own complexities related to substrate heating and target degradation.

Setting the Right Pressure for Your Goal

Your choice of operating pressure must be driven by the end goal for your specific film.

- If your primary focus is maximum film density and performance (e.g., optical coatings, semiconductor barriers): Start with the lowest stable pressure your system can maintain and only increase it if absolutely necessary to manage stress or uniformity.

- If your primary focus is high throughput for a less critical application (e.g., simple metallic layers, decorative coatings): Experiment to find the pressure that gives the peak deposition rate, but be sure to verify that film adhesion and integrity remain within your acceptable limits.

- If your primary focus is coating a complex 3D shape uniformly: A moderately higher pressure may be required to promote gas scattering, but this must be carefully balanced to avoid creating an overly porous and low-quality film.

Ultimately, mastering sputtering pressure is about understanding and controlling the energy of your depositing atoms to build the precise film structure you require.

Summary Table:

| Pressure Level | Effect on Film Quality | Effect on Deposition Rate | Typical Use Case |

|---|---|---|---|

| Low Pressure | High density, compact films, superior properties | Lower rate, but high-energy arrival | Optical coatings, semiconductor barriers |

| High Pressure | Porous, columnar structure, lower quality | Initial rate increase, then decreases due to scattering | High-throughput, less critical layers |

Struggling to optimize your sputtering process for the perfect balance of film quality and deposition rate? KINTEK specializes in high-performance lab equipment and consumables for precise thin-film deposition. Our experts can help you select the right sputtering system and parameters to achieve dense, high-quality films efficiently. Contact our team today to discuss your specific laboratory needs and discover how KINTEK solutions can enhance your research and production outcomes.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Evaporation Boat for Organic Matter

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

People Also Ask

- What is the speed of PECVD? Achieve High-Speed, Low-Temperature Deposition for Your Lab

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition