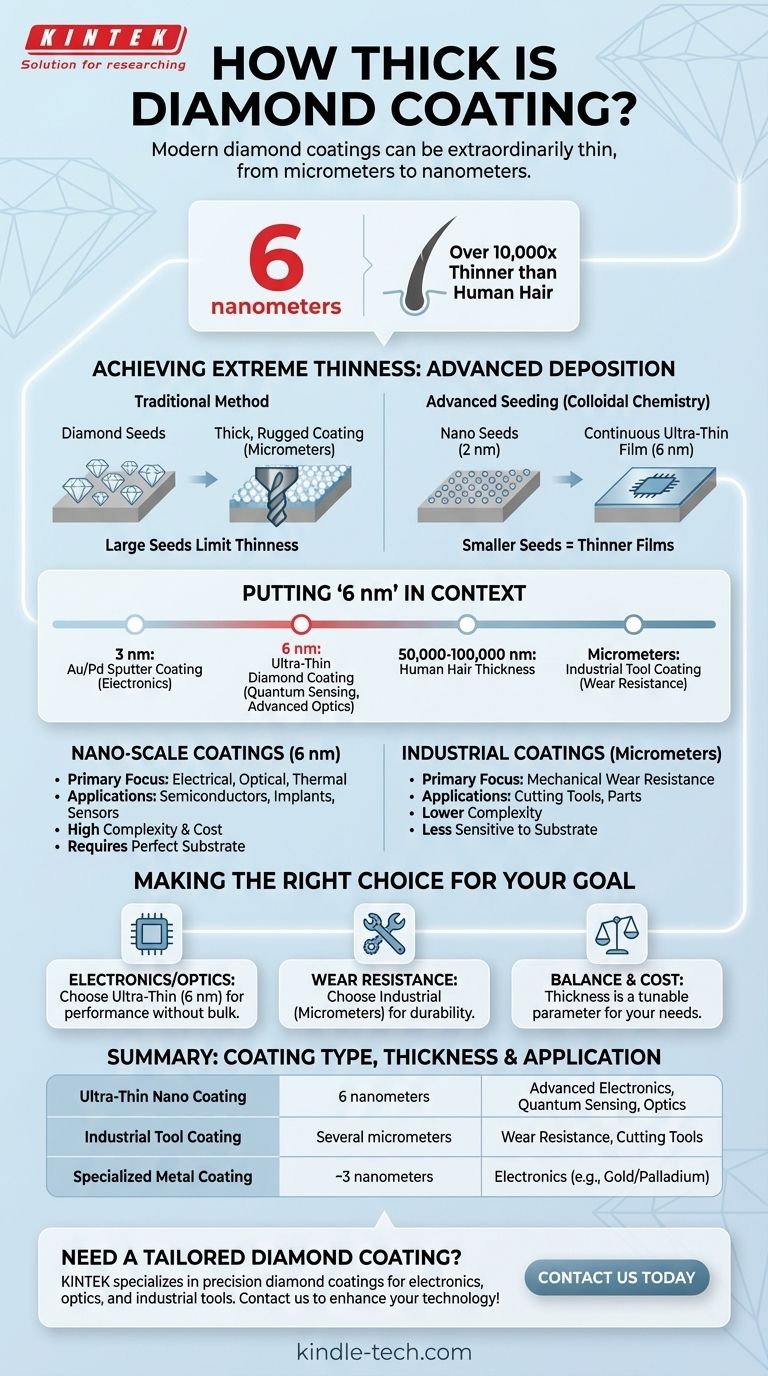

In short, modern diamond coatings can be extraordinarily thin. With recent advancements in deposition technology, it is now possible to produce uniform diamond coatings as thin as 6 nanometers. For scale, this is over 10,000 times thinner than a human hair.

The key takeaway is that "diamond coating" does not refer to a single thickness. The technology has evolved to a point where thickness is a precisely engineered parameter, ranging from several micrometers for industrial tools down to just a few nanometers for advanced electronics.

How Such Extreme Thinness is Achieved

The ability to create such ultra-thin films is not about simply applying a thinner layer. It relies on fundamentally new approaches to how the diamond is grown on a surface.

The Role of Diamond "Seeds"

Diamond coatings are not "painted on." Instead, they are grown in a process called chemical vapor deposition (CVD), which starts with nano-sized diamond particles, or "seeds," distributed on a surface. The final film grows from and connects these initial seeds.

Advanced Seeding Techniques

Historically, achieving a thin, continuous film was limited by the size of the initial diamond seeds. If the seeds are too large, the coating must be thick just to cover them and form a complete layer.

Recent breakthroughs use sophisticated methods, such as colloidal chemistry and the air oxidation of diamond particles, to dramatically reduce the seed size.

From 2 nm Seeds to a 6 nm Film

These advanced methods can produce diamond seed particles as small as 2 nanometers. Starting with such incredibly small and uniform seeds allows for the growth of a complete, continuous diamond film that is only 6 nanometers thick.

Putting "6 Nanometers" in Context

A 6 nm coating is a remarkable achievement that opens up entirely new applications for diamond's unique properties.

Comparison with Other Nanocoatings

This level of thinness places diamond coatings in the same category as other high-performance thin films. For perspective, specialized Gold/Palladium coatings used in electronics can be sputtered onto wafers at a thickness of just 3 nanometers.

Industrial vs. Nano-Scale Coatings

It's important to distinguish these nano-scale films from more traditional diamond coatings. The thick, rugged coatings used on cutting tools or wear-resistant parts are often measured in micrometers (thousands of nanometers), not single-digit nanometers.

The Impact on New Applications

An ultra-thin, perfectly uniform diamond layer enables technologies that were previously impossible. This includes applications in advanced semiconductors, quantum sensing, biocompatible implants, and high-performance optics where adding any significant bulk is not an option.

Understanding the Trade-offs

While incredibly thin coatings are a major advancement, the choice of thickness always involves balancing competing factors.

Thickness vs. Durability

An ultra-thin 6 nm film, while fully continuous, will not provide the same level of abrasion resistance as a 10-micrometer-thick coating on a drill bit. The primary function of nano-scale films is often electrical, thermal, or optical, not heavy-duty mechanical protection.

Complexity and Cost

The advanced colloidal chemistry and deposition methods required to produce nano-scale films are significantly more complex and costly than the processes used for creating thicker, industrial-grade coatings.

Substrate and Uniformity

At the nanometer scale, the smoothness and cleanliness of the underlying material (the substrate) become critically important. Achieving a perfectly uniform 6 nm film requires an equally perfect surface to build upon.

Making the Right Choice for Your Goal

The ideal thickness of a diamond coating is entirely dependent on the problem you are trying to solve.

- If your primary focus is advanced electronics, optics, or sensors: The availability of ultra-thin coatings (in the 6 nm range) is a critical enabling technology.

- If your primary focus is mechanical wear resistance for tools or parts: A much thicker coating, likely measured in micrometers, will be necessary to ensure durability and a long service life.

- If your primary focus is balancing performance and cost: The key is understanding that thickness is a tunable parameter that must be specified based on your application's unique demands.

Ultimately, the thickness of a diamond coating is not a single value but a highly engineered parameter tailored to its specific purpose.

Summary Table:

| Coating Type | Typical Thickness | Primary Application |

|---|---|---|

| Ultra-Thin Nano Coating | 6 nanometers | Advanced Electronics, Quantum Sensing, Optics |

| Industrial Tool Coating | Several micrometers | Wear Resistance, Cutting Tools |

| Specialized Metal Coating | ~3 nanometers | Electronics (e.g., Gold/Palladium) |

Need a diamond coating tailored to your specific application? KINTEK specializes in advanced lab equipment and consumables, including precision diamond coatings for electronics, optics, and industrial tools. Whether you require ultra-thin films for sensitive sensors or durable coatings for heavy-duty use, our expertise ensures optimal performance and reliability. Contact us today to discuss your project and discover how our solutions can enhance your technology!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- CVD Diamond for Thermal Management Applications

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Dressing Tools for Precision Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer

- What is CVD diamond coating? Grow a Super-Hard, High-Performance Diamond Layer

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers