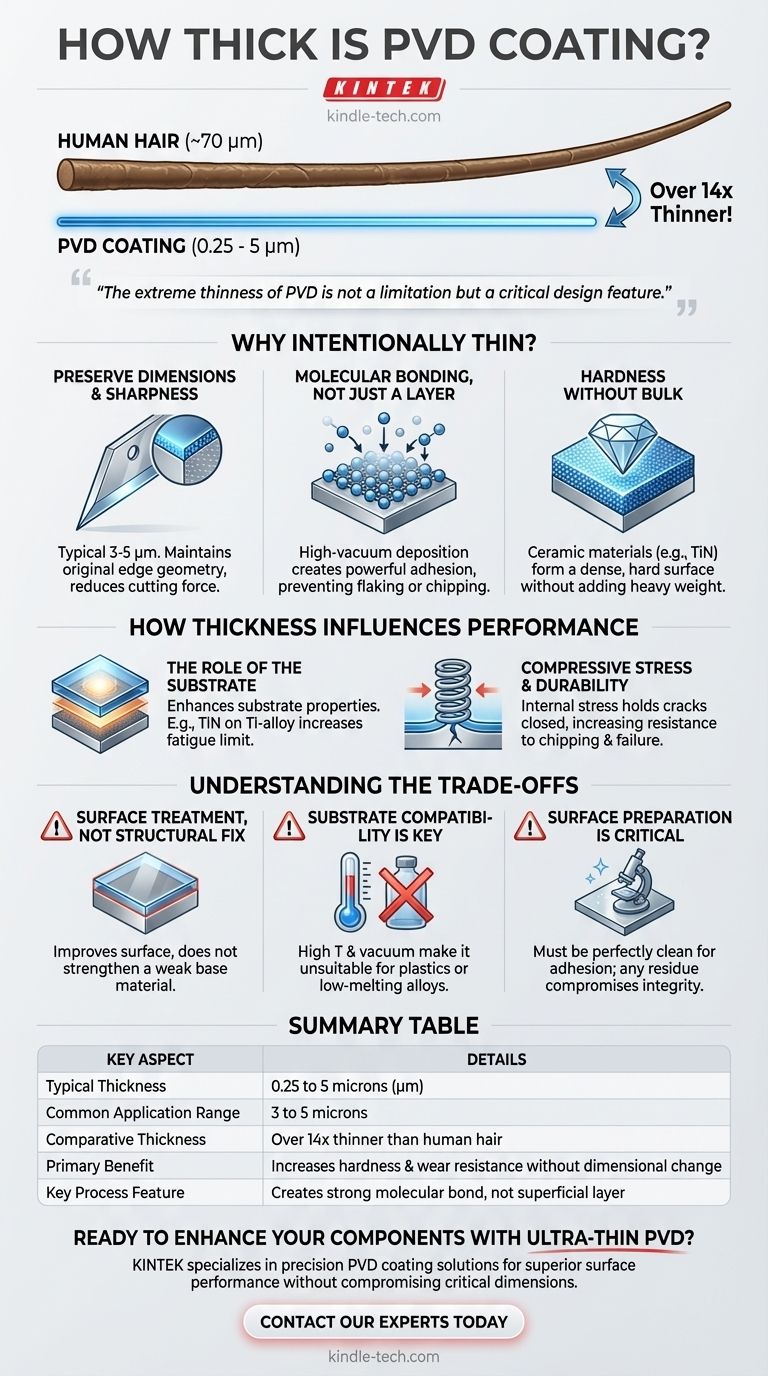

In most technical applications, a Physical Vapor Deposition (PVD) coating is exceptionally thin. The typical thickness ranges from 0.25 to 5 microns (μm), with many applications falling into the 3 to 5 micron range. For context, a single human hair is about 70 microns thick, making a PVD coating over 14 times thinner.

The extreme thinness of PVD is not a limitation but a critical design feature. It allows for a dramatic increase in surface hardness and wear resistance without altering the part's precise dimensions, weight, or sharpness.

Why PVD Coatings Are Intentionally Thin

The value of a PVD coating lies in its ability to fundamentally change the surface properties of a component on a molecular level. Its thinness is essential to achieving this without creating negative side effects.

Preserving Critical Dimensions and Sharpness

For components where precision is paramount, such as cutting tools, blades, or medical instruments, any added thickness can ruin functionality.

A thin PVD coating, often just 3-5 μm, adds immense hardness and lubricity while preserving the original sharpness of a blade’s edge. This reduces cutting force and heat generation during use.

Molecular Bonding, Not Just a Layer

PVD is not like painting. It is a high-vacuum deposition process where a solid material is vaporized and then deposited, atom by atom, onto the substrate.

This method, often conducted at temperatures between 250°C and 750°C, creates a powerful molecular bond. The result is a coating with extremely high adhesion that will not flake or chip.

Achieving Hardness Without Bulk

The incredible hardness of PVD coatings comes from the materials used, which are often ceramics like Titanium Nitride (TiN).

These materials form a dense, hard surface that protects the underlying material from wear and abrasion. The protection comes from the material's inherent properties, not from a thick, heavy layer.

How Thickness Influences Performance

While thin, the coating has a profound impact on the component's durability and function. It works in concert with the material it is applied to.

The Role of the Substrate

A PVD coating’s performance is determined by the underlying material, or substrate. The coating enhances the substrate's properties rather than just covering them up.

For example, applying a Titanium Nitride (TiN) coating to a high-performance titanium alloy (Ti-6Al-4V) can increase its fatigue limit and endurance, making the entire part more robust.

Compressive Stress and Durability

The PVD process creates compressive stress in the coating layer as it cools. This internal stress is a significant benefit.

It works to hold microscopic cracks together, preventing them from growing and spreading. This makes PVD-coated parts, especially tools used in interrupted cutting like milling, far more resistant to chipping and failure.

Corrosion and Temperature Resistance

The deposited film is highly resistant to corrosion, oxidation, and high temperatures. This thin barrier effectively seals the substrate from environmental factors that would otherwise cause it to degrade.

Understanding the Trade-offs

PVD is a powerful technology, but its effectiveness depends on understanding its intended use and limitations.

It's a Surface Treatment, Not a Structural Fix

A PVD coating dramatically improves surface properties like hardness and wear resistance. However, it does not change the bulk properties of the substrate.

It will not make a weak or soft base material structurally stronger. The core strength of the component must be appropriate for the application before the coating is ever applied.

Substrate Compatibility is Key

The process involves high temperatures and a high vacuum. This makes PVD unsuitable for materials that cannot withstand these conditions, such as many plastics or low-melting-point alloys.

Surface Preparation is Critical

The high-adhesion bond of a PVD coating can only be achieved on a perfectly clean, smooth, and uncontaminated surface. Any imperfection or residue on the substrate will compromise the coating's integrity and lead to failure.

Making the Right Choice for Your Application

The ideal thickness and coating material depend entirely on your goal.

- If your primary focus is precision and sharpness (e.g., cutting tools, medical instruments): The ultra-thin nature of PVD is a primary advantage, preserving critical edge geometry while adding hardness.

- If your primary focus is durability and wear resistance (e.g., watch cases, firearms, hardware): PVD provides a significant increase in surface hardness and corrosion resistance in a thin, lightweight form factor.

- If your primary focus is a specific decorative finish (e.g., jewelry, architectural fixtures): The process allows for a wide range of durable, vibrant colors and textures without adding perceptible thickness or weight.

Ultimately, the controlled thinness of a PVD coating is the key to enhancing a material's surface performance without compromising its fundamental design.

Summary Table:

| Key Aspect | Details |

|---|---|

| Typical Thickness | 0.25 to 5 microns (µm) |

| Common Application Range | 3 to 5 microns |

| Comparative Thickness | Over 14x thinner than a human hair (~70 µm) |

| Primary Benefit | Increases surface hardness & wear resistance without changing part dimensions |

| Key Process Feature | Creates a strong molecular bond, not just a superficial layer |

Ready to enhance your components with a durable, ultra-thin PVD coating?

KINTEK specializes in precision lab equipment and consumables, providing advanced PVD coating solutions for industries ranging from medical instruments to cutting tools. Our coatings deliver superior surface hardness, corrosion resistance, and longevity without compromising your part's critical dimensions.

Contact our experts today to discuss how our PVD coating services can solve your specific wear and performance challenges.

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Graphite Vacuum Continuous Graphitization Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- Does sintering use diffusion? The Atomic Mechanism for Building Stronger Materials

- Where is vacuum furnace used? Essential for Aerospace, Medical, and High-Tech Manufacturing

- What is the function of a vacuum furnace? Achieve High-Purity, Contamination-Free Thermal Processing

- Why is sintering easier in the presence of a liquid phase? Unlock Faster, Lower-Temperature Densification