To prevent clay from sticking, you must create a separation layer between the clay and the mold. For non-porous molds made of plastic or metal, this means using a physical barrier like newspaper or a release agent like cornstarch. For standard plaster molds, the primary release mechanism is the mold's own porosity, which pulls water from the clay and causes it to shrink away naturally.

The core principle is not simply to stop stickiness, but to correctly manage moisture. A dry, porous plaster mold is designed to release clay on its own. A non-porous mold lacks this ability and requires your intervention to create a boundary.

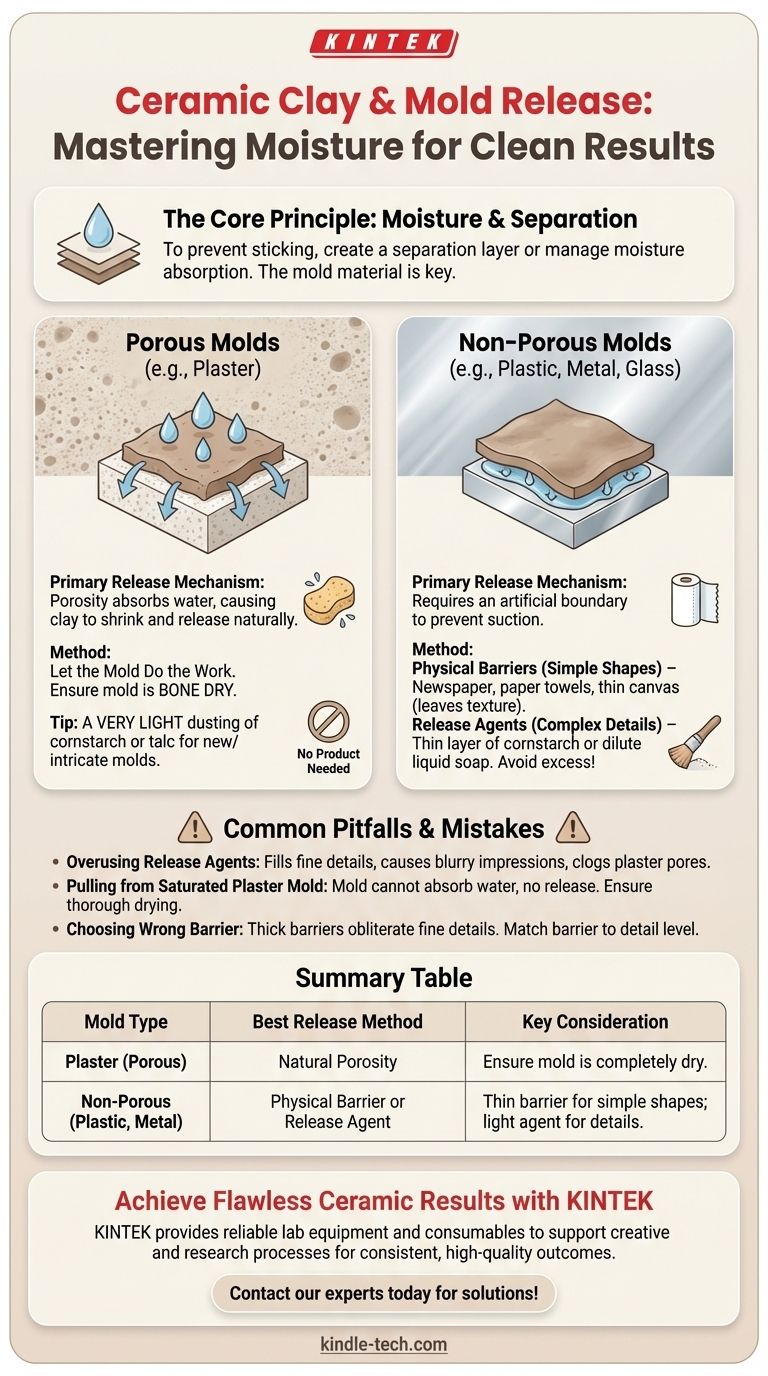

The Core Principle: Moisture and Separation

The interaction between wet clay and the mold surface determines whether you get a clean release or a frustrating mess. The material of the mold is the most important factor.

How Porous Molds Work (Plaster)

A standard ceramic mold is made of plaster. Plaster is porous, meaning it has microscopic channels that absorb water.

When you press moist clay into a dry plaster mold, the plaster immediately begins to draw water out of the clay surface it is touching. This causes the clay to stiffen and shrink slightly, pulling itself away from the mold walls naturally.

The Challenge of Non-Porous Molds (Plastic, Metal, Glass)

Non-porous molds do not absorb water. When wet clay is pressed against them, the water has nowhere to go.

This creates a powerful suction effect, effectively gluing the clay to the surface. Without a release mechanism, the clay will tear or deform when you try to remove it. This is why an artificial barrier is required.

Choosing the Right Release Method

Your choice of method should be dictated entirely by the type of mold you are using.

For Plaster Molds: Let the Mold Do the Work

For a dry plaster mold, the best release agent is often no agent at all. The porosity is the release mechanism.

If you still experience minor sticking, it may be due to a new mold or an intricate texture. A very light dusting of cornstarch or talc can help, but use it sparingly.

For Non-Porous Molds: Physical Barriers

As the reference material suggests, a simple physical barrier is highly effective for non-porous molds, especially those with simple curves.

Materials like newspaper, paper towels, or thin canvas create a definitive layer between the clay and the mold. The barrier peels away easily from the stiffened clay. Be aware that the texture of the barrier (e.g., the weave of the canvas) will be imprinted on your clay surface.

For Non-Porous Molds: Release Agents

For complex, detailed non-porous molds where a physical barrier would obscure the pattern, a release agent is the better choice.

Cornstarch is the most common and accessible option. Apply a very thin, even layer with a soft brush, blowing off any excess.

A dilute liquid soap solution (like Murphy Oil Soap mixed with water) can also be used. Apply a very thin film and allow it to dry before pressing in the clay.

Understanding the Trade-offs and Pitfalls

Using the wrong method or applying it incorrectly can create new problems.

Overusing Release Agents

The most common mistake is using too much release agent. An excess of cornstarch or talc will fill the fine details of your mold, resulting in a soft, blurry impression on your clay.

On a plaster mold, overuse can clog the pores, reducing the mold's ability to absorb water and shortening its effective lifespan.

Pulling from a Saturated Mold

The number one cause of clay sticking in a plaster mold is that the mold is already damp or saturated from previous use.

If the plaster cannot absorb water from the clay, it cannot release it. Always ensure your plaster molds are thoroughly dry before use. A dry mold feels neutral or slightly cool, while a damp one feels cold and clammy.

Choosing the Wrong Barrier

A thick physical barrier like heavy canvas will completely obliterate fine details in a mold. Match the thickness and texture of your barrier to the level of detail you want to preserve.

Making the Right Choice for Your Project

Follow these guidelines to ensure a clean release based on your specific situation.

- If you are using a dry plaster mold: Trust the mold's porosity to release the clay naturally before reaching for any product.

- If you are using a non-porous mold (plastic, metal) with a simple shape: A physical barrier like a paper towel or thin fabric is a simple and effective solution.

- If you are working with a highly detailed non-porous mold: Apply a very thin, even layer of a release agent like cornstarch or a commercial mold soap.

- If your clay is sticking in a plaster mold: Your first step should always be to ensure the mold is completely bone dry.

Understanding the relationship between your clay, your mold material, and moisture is the key to achieving a perfect release every time.

Summary Table:

| Mold Type | Best Release Method | Key Consideration |

|---|---|---|

| Plaster (Porous) | Mold's natural porosity (water absorption) | Ensure the mold is completely dry before use. |

| Non-Porous (Plastic, Metal) | Physical barrier (e.g., paper towel) or release agent (e.g., cornstarch) | Use a thin barrier for simple shapes; a light dusting of agent for complex details. |

Achieve flawless ceramic results with the right equipment.

Struggling with mold release or other lab material challenges? KINTEK specializes in providing reliable lab equipment and consumables to support your creative and research processes. Our products are designed to help you achieve consistent, high-quality outcomes.

Contact our experts today to find the perfect solutions for your laboratory needs!

Visual Guide

Related Products

- Special Shape Press Mold for Lab

- Polygon Press Mold for Lab

- Assemble Lab Cylindrical Press Mold

- Square Lab Press Mold for Laboratory Applications

- Ball Press Mold for Lab

People Also Ask

- What functions do high-purity graphite molds serve for IZO targets? Ensure Density and Prevent Sintering Cracks

- What technical characteristics are required for specialty pressure molds used in the compaction of Li10GeP2S12? Expert Tips

- Why are custom pressure molds used during the hot pressing process for solid polymer electrolytes?

- How do custom graphite molds contribute to Al-20% Si/graphite flake composites? Optimize Microstructure & Conductivity

- Why are high-strength graphite molds essential for vacuum hot pressing? Optimize Your Diamond/Copper Composites