Ultimately, the only way to be certain your water filter is working properly is to test your water. By analyzing a water sample from before and after it passes through your filter, you can measure its effectiveness in removing specific contaminants. This process, known as performance testing, provides definitive proof that goes beyond simple observation.

While indicators like water flow and taste can offer clues, they are not reliable measures of a filter's performance against invisible contaminants. The only way to truly verify your water's safety is through quantitative testing that compares your unfiltered tap water to your filtered water.

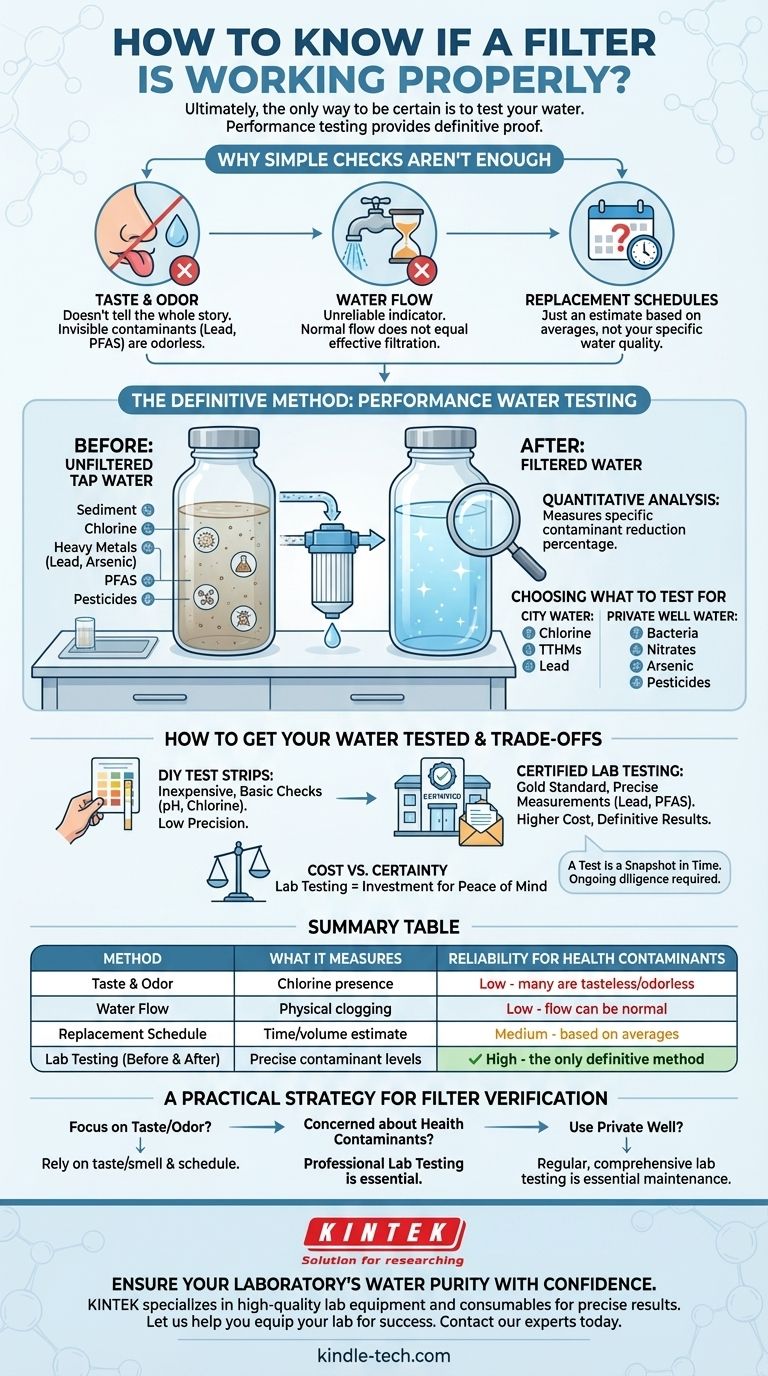

Why Simple Checks Aren't Enough

Many people rely on indirect signs to judge their filter's status. While these have some value, they can provide a false sense of security.

Taste and Odor Don't Tell the Whole Story

A primary reason for using a filter is to remove unpleasant tastes and odors, most commonly from chlorine used in municipal water treatment.

If your water starts to taste or smell like chlorine again, your filter's activated carbon is likely exhausted. However, many of the most serious contaminants—such as lead, arsenic, pesticides, and PFAS—are odorless and tasteless. A filter can fail to remove these long before the taste of chlorine returns.

Water Flow Is an Unreliable Indicator

A significant drop in water pressure or flow rate is a clear sign that your filter is clogged with sediment and needs replacement.

However, a filter can continue to have a strong flow rate even after its chemical filtration media (like activated carbon or ion exchange resin) is exhausted. The water passes through, but it is no longer being effectively purified. Normal flow does not equal effective filtration.

Replacement Schedules Are Just an Estimate

Following the manufacturer's recommended replacement schedule (e.g., every six months or 40 gallons) is a critical maintenance practice.

These recommendations are based on average usage and average water quality. If your local water has higher-than-average levels of sediment or contaminants, your filter may be exhausted weeks or even months before its scheduled replacement date.

The Definitive Method: Performance Water Testing

To move from assumption to certainty, you must measure what the filter is actually removing.

The Principle of "Before and After"

The logic is simple but powerful. You must establish a baseline by testing your unfiltered tap water. This tells you what contaminants are present and at what concentration.

You then test a sample of water that has passed through the filter. Comparing the "before" and "after" results provides a clear, quantitative report on your filter's reduction percentage for each specific contaminant.

Choosing What to Test For

You don't need to test for every possible substance. Focus on the contaminants most relevant to your water source and your filter's claims.

For city water, common concerns include chlorine, disinfection byproducts (TTHMs), and lead from older plumbing. For private well water, you might test for bacteria, nitrates, arsenic, and pesticides. Check your local water quality report or with your health department to identify regional concerns.

How to Get Your Water Tested

You have two primary options, each with different levels of precision and cost.

- At-Home DIY Test Strips: These are inexpensive and useful for basic checks like chlorine, pH, and water hardness. They provide a general indication but lack the precision needed for verifying the removal of health-concerning contaminants.

- Certified Laboratory Testing: This is the gold standard for accuracy. You order a kit from an independent, certified lab. They provide vials and instructions for collecting both tap and filtered water samples, which you then mail back for analysis. This is the only way to get precise measurements for contaminants like lead, mercury, or PFAS.

Understanding the Trade-offs

Objective analysis requires acknowledging the costs and limitations of testing.

Cost vs. Certainty

Professional lab testing is an investment. A comprehensive test can range from under a hundred to several hundred dollars. You are paying for certainty and peace of mind. For many, this cost is a worthwhile trade-off for confidence in the safety of their drinking water.

A Test Is a Snapshot in Time

A water test reveals the quality of your water on the day you take the sample. Water quality, especially from wells, can fluctuate seasonally or after heavy rains. The test confirms the filter is working now, but ongoing diligence is still required.

Verifying Filter-Specific Claims

No single filter removes everything. A test might reveal your pitcher filter is excellent at removing chlorine but does nothing for the nitrates found in your well water. This isn't a sign the filter is "broken," but that it isn't designed for that purpose. Testing helps you confirm a filter is meeting its advertised performance claims.

A Practical Strategy for Filter Verification

Your approach should align with your primary goal for water filtration.

- If your primary focus is improving taste and odor: Relying on the taste/smell test and strictly following the manufacturer's replacement schedule is a reasonable approach.

- If you are concerned about specific health-related contaminants (like lead, arsenic, or PFAS): Professional "before and after" laboratory testing is the only method that provides a definitive answer.

- If you use a private well for your drinking water: Regular, comprehensive lab testing (typically annually) should be considered essential home maintenance, providing critical information for selecting and verifying any filtration system.

Ultimately, verifying your filter's performance transforms you from a passive consumer into an informed steward of your own health.

Summary Table:

| Method | What It Measures | Reliability for Health Contaminants |

|---|---|---|

| Taste & Odor | Chlorine presence | Low - many contaminants are tasteless/odorless |

| Water Flow | Physical clogging | Low - flow can be normal even when media is exhausted |

| Replacement Schedule | Time/volume estimate | Medium - based on averages, not your specific water |

| Lab Testing (Before & After) | Precise contaminant levels (e.g., lead, PFAS) | High - the only definitive method |

Ensure your laboratory's water purity with confidence.

Just as verifying a water filter's performance is critical for safety, reliable lab equipment is fundamental for accurate, reproducible results.

KINTEK specializes in high-quality lab equipment and consumables designed to meet the rigorous demands of modern laboratories. Whether you need precise filtration systems, pure water solutions, or any other lab essentials, our products help you maintain the highest standards of quality and safety.

Let us help you equip your lab for success. Contact our experts today to discuss your specific needs and discover how KINTEK can support your research and testing goals.

Visual Guide

Related Products

- Electrolytic Electrochemical Cell for Coating Evaluation

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- High Performance Laboratory Stirrers for Diverse Applications

People Also Ask

- What type of wastes are used for the pyrolysis treatment? Unlock Value from Organic Waste Streams

- What is the temperature of activated carbon regeneration? Unlock the 1000°F Process for Reuse

- What are the defects of sintered metal? Understanding Porosity, Cracking & Distortion

- What is a filter press in industry? A Guide to High-Pressure Solid-Liquid Separation

- Does tensile strength increase with heat treatment? How to Engineer the Perfect Metal Properties

- Is deposition the reverse of sublimation? Understanding the Direct Phase Transition

- Does KBr absorb IR radiation? Why It's the Go-To Matrix for Clean Spectra

- What are the essential controllable parameters in a heat treatment process? Master Temperature, Time, Atmosphere & Cooling