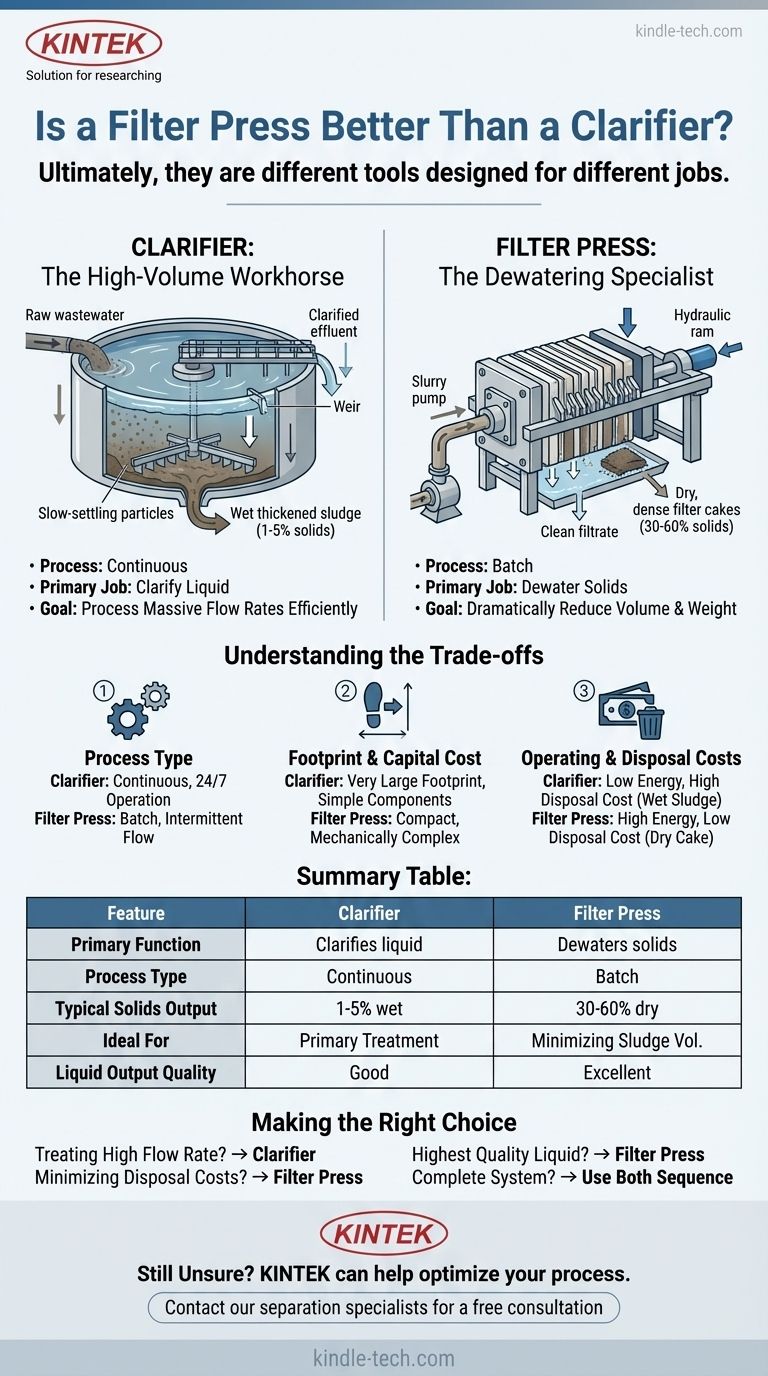

Ultimately, a filter press is not "better" than a clarifier; they are different tools designed for different jobs. A clarifier is built to handle very large volumes of liquid and remove the bulk of settleable solids, but the resulting sludge is still very wet. A filter press is a dewatering device that takes a thickened slurry and uses high pressure to produce a very dry solid cake and a very clean liquid filtrate.

The core distinction is this: a clarifier's main job is to clarify the liquid, while a filter press's main job is to dewater the solids. They are not competitors; in many industrial processes, they are used together in sequence.

What is a Clarifier? The High-Volume Workhorse

A clarifier is the first line of defense in many large-scale water treatment and separation processes. Its design is based on a simple principle: gravity.

How It Works: Gravity and Settling

Wastewater or slurry is fed into a large, circular tank. The flow is slowed dramatically, giving heavier solid particles time to settle to the sloped bottom of the tank.

A slow-moving rake mechanism gently pushes this settled sludge toward a central collection point. Simultaneously, the now-clarified liquid overflows from the top edge (the weir) of the tank.

What It Produces

A clarifier separates a single input stream into two distinct outputs:

- Clarified Effluent: A large volume of water with most of the settleable solids removed. It is not perfectly pure and still contains fine, non-settling suspended particles.

- Thickened Sludge: A low-solids slurry (typically 1-5% solids by weight) that is collected from the bottom. It is still liquid enough to be pumped.

Ideal Use Cases

Clarifiers are the go-to solution for primary treatment where the goal is to process massive flow rates efficiently. They are common in municipal wastewater plants, mining operations, and manufacturing facilities to handle the initial, high-volume separation task.

What is a Filter Press? The Dewatering Specialist

A filter press is a batch-processing machine designed for intensive solid-liquid separation. It is not meant for treating raw, high-volume wastewater directly.

How It Works: Pressure and Filtration

Slurry (often the thickened sludge from a clarifier) is pumped at high pressure into a series of chambers. These chambers are lined with filter cloths that allow liquid to pass through but capture the solid particles.

As more slurry is pumped in, the solids build up and are compressed, squeezing out remaining liquid. Once the cycle is complete, the press opens, and the compressed solids are discharged as a dry, manageable cake.

What It Produces

A filter press also produces two outputs, but they are significantly different from a clarifier's:

- Clean Filtrate: A very clean liquid stream with extremely low levels of suspended solids, as it has been physically forced through a filter medium.

- Dewatered Filter Cake: A dense, solid cake with high solids content (typically 30-60% or more). This material is often dry enough to be handled with a shovel or front-end loader.

Ideal Use Cases

Filter presses excel at sludge dewatering. Their purpose is to dramatically reduce the volume and weight of waste solids to minimize disposal costs or, in some cases, to recover a valuable solid product.

Understanding the Trade-offs

Choosing between these technologies—or deciding to use them together—involves clear operational and financial trade-offs.

Process Type: Continuous vs. Batch

A clarifier operates continuously, with a constant inflow and outflow. This makes it ideal for integrating into a plant-wide process that runs 24/7.

A filter press is a batch operation. It fills, presses, discharges, and then repeats the cycle. This requires more complex automation or operator intervention and introduces an intermittent flow.

Footprint and Capital Cost

Clarifiers require a very large physical footprint due to the need for long residence times for gravity settling. Their mechanical components are relatively simple.

Filter presses are more compact for the volume they process but are mechanically complex, high-pressure machines, which can increase their capital and maintenance costs.

Operating and Disposal Costs

Clarifiers have low energy consumption but may require chemical additives (flocculants or coagulants) to improve settling performance. The primary cost concern is the disposal of the large volume of wet sludge it produces.

Filter presses have higher energy costs (due to high-pressure pumps) and ongoing costs for replacing filter cloths. However, they can drastically reduce sludge disposal costs by converting a large volume of liquid sludge into a small volume of solid cake, which is cheaper to transport and landfill.

Making the Right Choice for Your Goal

The correct equipment choice is entirely dependent on the specific problem you are trying to solve.

- If your primary focus is treating a high flow rate of wastewater: A clarifier is the correct tool for the job. It efficiently handles large volumes for primary separation.

- If your primary focus is minimizing final sludge disposal costs: A filter press is the superior choice. It produces a dry, compact cake that is far cheaper to handle and dispose of than wet sludge.

- If your primary focus is achieving the highest quality liquid output: A filter press will produce a much cleaner filtrate than a clarifier.

- If your primary focus is building a complete dewatering system: Use both. A clarifier performs the initial bulk separation, and a filter press then dewaters the resulting sludge from the clarifier's underflow.

By understanding their distinct roles in the separation process, you can select the technology that delivers the most effective and economical outcome for your operation.

Summary Table:

| Feature | Clarifier | Filter Press |

|---|---|---|

| Primary Function | Clarifies large volumes of liquid | Dewaters solids into a dry cake |

| Process Type | Continuous | Batch |

| Typical Solids Content Output | 1-5% (wet sludge) | 30-60% (dry cake) |

| Ideal For | Primary treatment of high-flow wastewater | Minimizing sludge volume and disposal costs |

| Liquid Output Quality | Good (clarified effluent) | Excellent (clean filtrate) |

Still Unsure Which Solution is Right for Your Process?

KINTEK specializes in lab equipment and consumables, serving the precise separation and dewatering needs of industrial and research laboratories. Our experts can help you analyze your specific slurry characteristics and volume requirements to determine the most efficient and cost-effective solution—whether it's a clarifier, a filter press, or an integrated system.

Let us help you optimize your process and reduce disposal costs.

Contact our separation specialists today for a free consultation

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Double Plate Heating Press Mold for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- Why is KBr used as a mulling agent in IR? Achieve Clear, Accurate Solid Sample Analysis

- What role does a laboratory hydraulic press play in pellet-type electrode fabrication? Enhancing Solid-State Performance

- What is the ratio of KBr and sample in IR? Achieve Perfect Sample Concentration for Clear IR Spectra

- How do you prepare samples for infrared spectroscopy? Master Solid, Liquid & Gas Techniques