In a direct comparison, a properly executed aluminum weld is generally stronger than a brazed joint. Welding achieves this by melting and fusing the base aluminum parts, creating a continuous, homogenous structure that can be as strong as the original material. However, this simple answer overlooks the critical context: "strength" is only one of many factors, and for many applications, brazing is the superior joining method.

The question isn't simply which process is "stronger," but which process creates a joint that best meets the total requirements of your application. Focusing only on tensile strength can lead you to choose a process that introduces other failures, such as distortion or thermal stress.

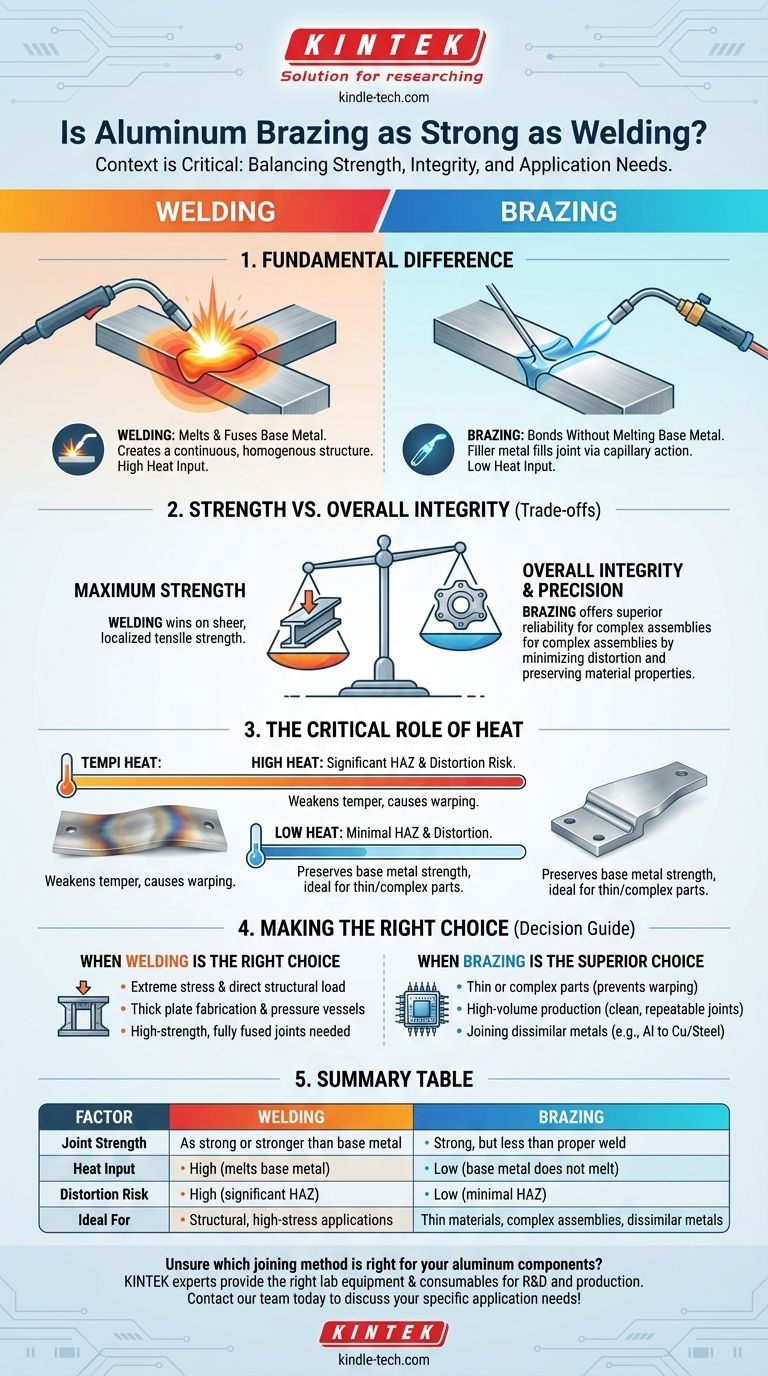

Understanding the Fundamental Difference

The divergence in strength begins with the core mechanism of each process. They are fundamentally different ways of joining metal, each with its own effect on the material's integrity.

How Welding Creates Strength

Welding works by melting the base aluminum along with a filler material. This creates a molten pool that, upon cooling, fuses the components together into a single, continuous piece. A properly designed and executed weld can be as strong, or even stronger, than the base metal it joins.

How Brazing Creates Strength

Brazing, in contrast, uses a filler metal with a lower melting point than aluminum. The base metal is heated, but it never melts. The brazing filler metal is drawn into the tight-fitting joint by capillary action, creating a strong metallurgical bond between the filler and the surface of the aluminum parts.

The Critical Role of Heat

The most significant difference is temperature. Welding requires much higher temperatures to melt the aluminum, creating a large Heat-Affected Zone (HAZ). This zone can weaken the temper of the aluminum, reduce its strength, and cause significant warping and distortion.

Brazing uses much lower temperatures. This results in a minimal HAZ, preserving more of the base metal's original strength and drastically reducing the risk of distortion—a crucial advantage when working with thin materials or complex assemblies.

The Trade-offs: Strength vs. Overall Integrity

While welding wins on sheer, localized strength, brazing often produces a more reliable finished assembly. The choice involves balancing the need for ultimate tensile strength against other critical performance factors.

When Welding is the Right Choice

Welding is the preferred method for applications where the joint will be under extreme stress or direct structural load. Think of thick plate fabrication, pressure vessels, or structural frames where the joint's ability to match the base metal's strength is non-negotiable.

When Brazing is the Superior Choice

Brazing excels where welding introduces unacceptable compromises. The lower heat input makes it ideal for delicate or complex parts that would warp or be damaged by the intense heat of welding.

Furthermore, brazing allows for the creation of neat, clean joints over large surface areas or in multiple locations at once (e.g., in a furnace), making it perfect for high-volume manufacturing like automotive radiators or HVAC components.

Joining Dissimilar Metals

A key advantage, as noted in the references, is that brazing can easily join aluminum to other metals like copper or steel. Welding these combinations is often difficult or impossible due to their vast differences in melting points and metallurgical properties.

Making the Right Choice for Your Application

Selecting the correct process requires you to look beyond a simple strength chart and evaluate the primary goal of your project.

- If your primary focus is maximum load-bearing capacity in a simple, robust structure: Choose welding for its ability to create a fully fused, high-strength joint.

- If your primary focus is joining thin materials or a complex assembly without distortion: Choose brazing to protect the integrity and dimensions of your finished part.

- If your primary focus is high-volume production with repeatable, clean joints: Choose brazing for its scalability and aesthetic finish.

- If your primary focus is joining aluminum to another type of metal: Brazing is the most reliable and effective solution.

Ultimately, the best process is the one that delivers a successful final part, and that often depends on much more than just strength alone.

Summary Table:

| Factor | Welding | Brazing |

|---|---|---|

| Joint Strength | As strong or stronger than base metal | Strong, but generally less than a proper weld |

| Heat Input | High (melts base metal) | Low (base metal does not melt) |

| Distortion Risk | High (significant HAZ) | Low (minimal HAZ) |

| Ideal For | Structural, high-stress applications | Thin materials, complex assemblies, dissimilar metals |

Unsure which joining method is right for your aluminum components? The experts at KINTEK are here to help. We specialize in providing the right lab equipment and consumables to support your R&D and production processes, whether you're developing welding procedures or optimizing brazing cycles. Let us help you achieve strong, reliable, and distortion-free joints. Contact our team today to discuss your specific application needs!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is vacuum brazing? The Ultimate Guide to High-Purity, Flux-Free Metal Joining

- Why would you braze instead of weld? Preserve Material Integrity and Join Dissimilar Metals

- How is the greatest joint strength obtained in brazing? Master the 3 Keys to Superior Metallurgical Bonds

- What is the basic of brazing? A Guide to Strong, Low-Heat Metal Joining

- Why would you braze instead of solder? For Superior Joint Strength and High-Temperature Performance