Yes, it is entirely possible to make fuel from plastic. This process, known as chemical recycling or thermal depolymerization, breaks down plastic waste into valuable hydrocarbons. These can then be refined into various fuels, including a crude oil substitute, diesel, and even clean-burning hydrogen gas that can power vehicles.

While the technology to convert plastic waste into usable fuel is a reality, its role is not to replace traditional recycling but to serve as a powerful solution for plastics that are otherwise destined for a landfill. Its viability hinges on process efficiency, economic conditions, and its net environmental impact.

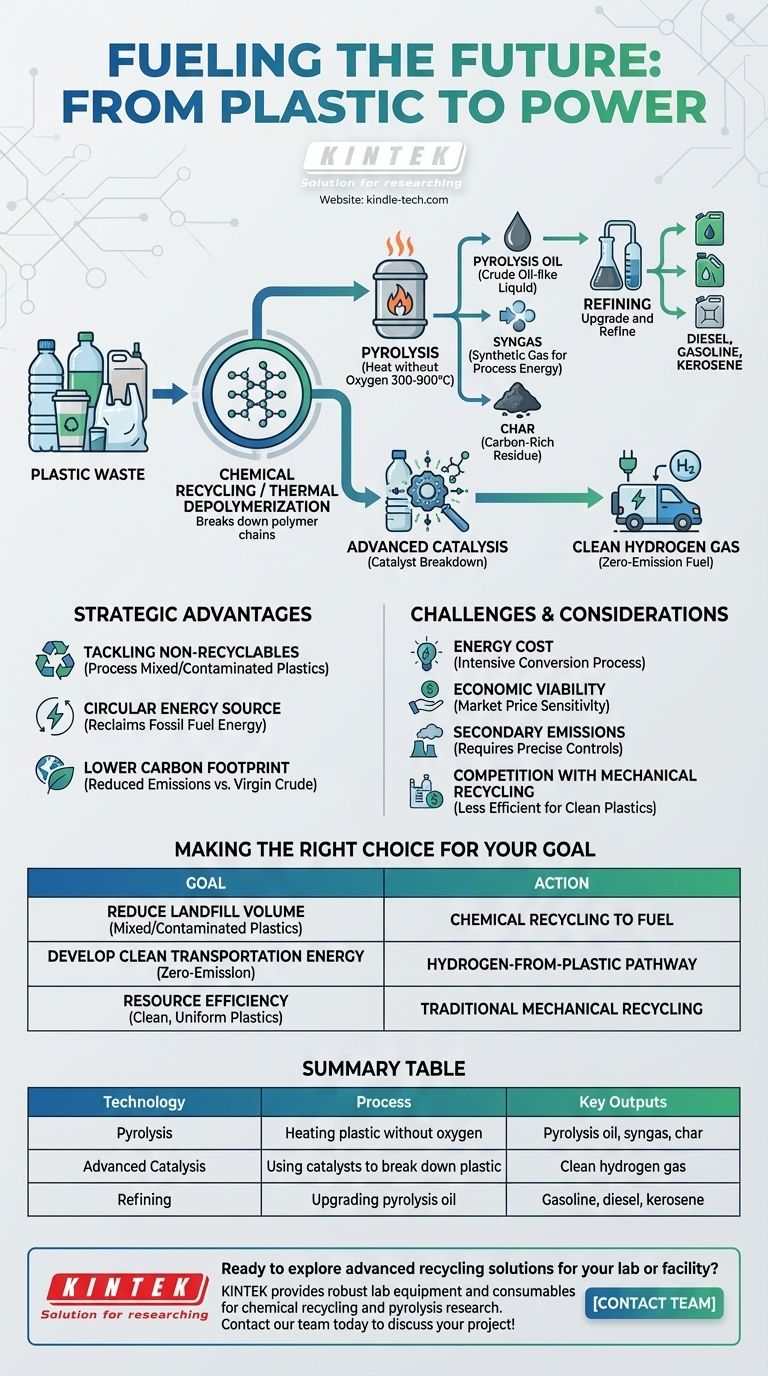

How Plastic Becomes Fuel: The Core Technologies

The fundamental principle behind converting plastic to fuel involves breaking the long, complex polymer chains that make up plastic into shorter, simpler hydrocarbon molecules, which are the building blocks of liquid and gas fuels.

The Principle of Pyrolysis

Pyrolysis is the most common method used today. It involves heating plastic waste to very high temperatures (300-900°C) in an environment with no oxygen.

This process, akin to high-temperature pressure cooking, prevents the plastic from burning and instead causes it to thermally crack. The output is typically a mix of three things: a crude oil-like liquid called pyrolysis oil, a synthetic gas (syngas), and a solid, carbon-rich residue called char.

From Raw Output to Refined Fuel

The pyrolysis oil produced is not yet a ready-to-use fuel. Much like crude oil drilled from the ground, it must be upgraded and refined to create consistent, high-quality products like gasoline, diesel, or kerosene. The syngas can be used to power the pyrolysis process itself, improving its energy efficiency.

An Alternative Path: Hydrogen Fuel

Researchers are also pioneering more advanced methods. As noted by Swansea University, specific catalysts can be used to break down plastics, generating clean hydrogen gas as the primary output. This bypasses the oil-refining stage and produces a zero-emission fuel for use in hydrogen fuel cell vehicles.

The Strategic Advantages of Plastic-to-Fuel

Converting waste plastic into fuel addresses two major global challenges simultaneously: plastic pollution and the need for new energy sources.

Tackling Non-Recyclable Plastics

A key advantage of this technology is its ability to process plastic waste that traditional mechanical recycling cannot handle. This includes mixed, contaminated, or multi-layered plastics that would otherwise end up in landfills or incinerators.

Creating a Circular Energy Source

This process effectively closes the loop on plastic's life cycle. Since plastics are originally derived from fossil fuels, converting them back into fuel reclaims the energy embedded within them, creating a form of circular, waste-to-energy system.

A Lower Carbon Footprint

When compared to extracting, transporting, and refining virgin crude oil, producing fuel from existing plastic waste can result in a lower overall carbon footprint. It avoids the environmental disruption of drilling and prevents the release of methane, a potent greenhouse gas, from plastics degrading in landfills.

Understanding the Trade-offs and Challenges

While promising, plastic-to-fuel technology is not a perfect solution and comes with significant operational and environmental considerations.

The Energy Cost of Conversion

The pyrolysis process is energy-intensive, requiring substantial heat to break down the polymers. For the technology to be truly sustainable, the energy yield from the fuel produced must be significantly greater than the energy required to run the plant.

Economic Viability

The business case for plastic-to-fuel is heavily influenced by the market price of crude oil. When oil prices are low, the fuel produced from plastic can be more expensive and struggle to compete. The cost of collecting and preparing the plastic feedstock is also a major factor.

Potential for Secondary Emissions

If not managed with precise controls, thermal conversion processes can create and release toxic compounds. Ensuring that the facility captures and treats all potential pollutants is critical to preventing air and water contamination.

Competition with Mechanical Recycling

For clean and sorted plastics like PET (bottles) and HDPE (jugs), traditional mechanical recycling is often the more energy-efficient and environmentally sound choice. Melting a bottle to make a new bottle preserves the material in its solid form and typically requires less energy than breaking it down into fuel to be burned.

Making the Right Choice for Your Goal

The decision to use plastic-to-fuel technology should be based on the specific type of waste and the desired outcome.

- If your primary focus is reducing landfill volume for mixed or contaminated plastics: Chemical recycling into fuel is a valuable and effective alternative to landfilling these hard-to-recycle materials.

- If your primary focus is developing clean transportation energy: The emerging hydrogen-from-plastic pathway offers a promising long-term solution for producing a zero-emission vehicle fuel.

- If your primary focus is resource efficiency for clean, uniform plastics (like PET bottles): Traditional mechanical recycling remains the more sustainable and energy-efficient option.

By treating plastic-to-fuel as a specialized tool for problematic waste streams, we can strategically integrate it into a broader, more effective waste management hierarchy.

Summary Table:

| Technology | Process | Key Outputs |

|---|---|---|

| Pyrolysis | Heating plastic without oxygen | Pyrolysis oil, syngas, char |

| Advanced Catalysis | Using catalysts to break down plastic | Clean hydrogen gas |

| Refining | Upgrading pyrolysis oil | Gasoline, diesel, kerosene |

Ready to explore advanced recycling solutions for your lab or facility? KINTEK specializes in providing the robust lab equipment and consumables needed to support research and development in chemical recycling and pyrolysis processes. Whether you're developing new catalysts or scaling up fuel production, our expertise can help you achieve your sustainability goals. Contact our team today to discuss how we can support your project with reliable, high-performance laboratory supplies.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

People Also Ask

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds