When evaluating plastic pyrolysis, its energy efficiency is a critical but complex question. The process is not inherently efficient; it is endothermic, meaning it requires a significant and continuous input of thermal energy to break down plastic polymers. However, a well-designed pyrolysis system can achieve a positive net energy balance by cleverly using the gaseous fuels it co-produces to power its own heating requirements, making the overall operation energy-positive.

The energy efficiency of plastic pyrolysis is not a fixed value but a variable outcome. The central challenge is achieving a positive Net Energy Balance, where the energy value of the produced fuel (pyrolysis oil) exceeds the total energy consumed by the entire process, from feedstock preparation to reactor operation.

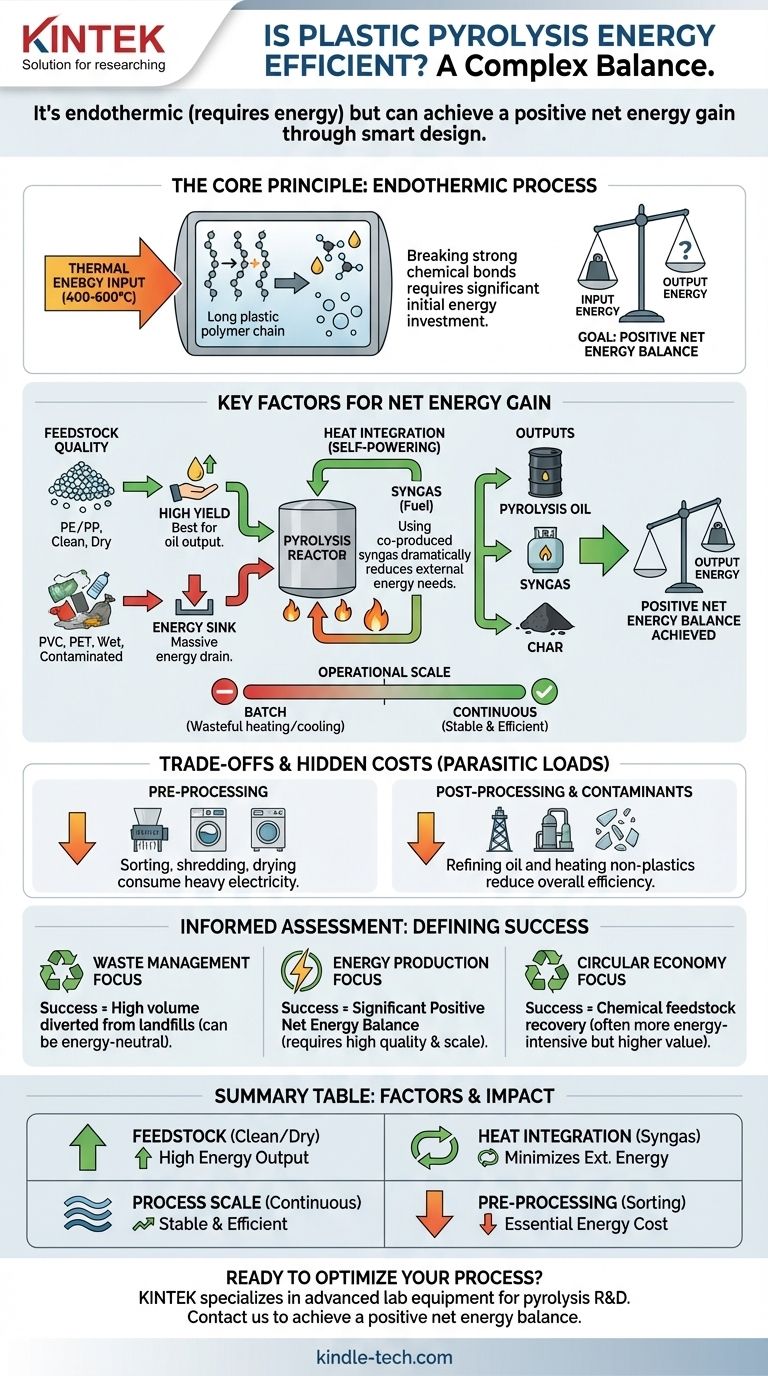

The Core Principle: An Endothermic Process

To properly assess efficiency, you must first understand the fundamental thermodynamics at play. Pyrolysis is not an energy source; it is an energy conversion technology.

Breaking Bonds Requires Energy

Plastic polymers are long, stable chains of molecules. Pyrolysis works by heating these plastics in an oxygen-free environment to a high temperature (typically 400-600°C), which breaks these strong chemical bonds.

This bond-breaking process requires a substantial energy investment. This initial energy cost is the primary reason pyrolysis cannot be considered "free" energy.

The Goal: A Net Energy Gain

The output of pyrolysis includes pyrolysis oil (a synthetic crude), syngas (a mix of flammable gases like hydrogen and methane), and char (solid carbon). Both the oil and gas have significant stored energy.

An "energy efficient" plant is one where the energy content of these outputs, particularly the oil, is greater than the total energy required to run the entire system.

Key Factors Determining Energy Efficiency

Whether a specific pyrolysis operation is energy-positive or a net energy drain depends almost entirely on feedstock quality and system design.

Feedstock Quality is Paramount

The type and condition of the plastic waste are the most important variables. Mixed, dirty, and wet plastics are significant energy sinks.

High-quality feedstocks like polyethylene (PE) and polypropylene (PP) yield the most oil. Problematic plastics like PVC release chlorine, creating corrosive acids, while PET produces a lower-quality oil and can clog equipment.

Crucially, any moisture in the feedstock must be boiled off, which consumes a massive amount of thermal energy before the pyrolysis process can even begin.

Process Technology and Heat Integration

The most critical design feature for efficiency is heat integration. The syngas co-produced during the reaction is a valuable fuel.

Efficient plants capture this syngas and burn it in a dedicated burner to provide the heat needed to sustain the pyrolysis reaction. This self-powering capability dramatically reduces the need for external energy sources (like natural gas or electricity), turning a potential energy sink into an energy-positive loop.

Operational Scale and Consistency

Large-scale, continuous-feed reactors are generally far more energy-efficient than small batch reactors.

Continuous systems maintain a stable operating temperature, avoiding the massive energy waste of repeatedly heating and cooling a large reactor mass. This operational stability is key to optimizing energy recovery.

Understanding the Trade-offs and Inefficiencies

An objective assessment requires acknowledging the hidden energy costs, or "parasitic loads," that are often overlooked in simplistic calculations.

The "Parasitic Load" of Pre-processing

Plastic waste does not arrive ready for pyrolysis. It must be sorted, shredded, washed, and dried.

Each of these steps requires heavy machinery that consumes significant amounts of electricity. This pre-processing energy expenditure must be included in any honest calculation of the plant's overall Net Energy Balance.

The Challenge of Contaminants

Non-plastic contaminants (metal, glass, paper) act as heat sinks within the reactor, absorbing energy without contributing to the fuel yield. They reduce the overall thermal efficiency of the system.

Energy Lost in Post-processing

The raw pyrolysis oil, often called bio-crude or TPO (Tire Pyrolysis Oil), is not a drop-in replacement for diesel. It is acidic, unstable, and contains contaminants.

Upgrading this oil into a usable fuel through processes like hydrotreating or distillation requires further energy-intensive refining steps. This post-processing energy cost is another critical factor in the life-cycle energy assessment.

Making an Informed Assessment for Your Goal

The viability of pyrolysis depends entirely on your primary objective. You must define success before you can measure efficiency.

- If your primary focus is waste management: A pyrolysis plant that is merely energy-neutral can be a major success if it effectively diverts a high volume of non-recyclable plastic from landfills.

- If your primary focus is energy production: You must demand a significant positive Net Energy Balance, focusing on high-quality, clean feedstock and a large-scale continuous process with excellent heat integration.

- If your primary focus is creating a circular economy: The goal is converting plastic back into chemical feedstocks ("monomers") for new plastics. This is often more energy-intensive than producing fuel but provides a higher-value environmental benefit by closing the material loop.

Ultimately, viewing plastic pyrolysis as a complex chemical conversion process—not a simple energy source—is the first step toward a realistic and successful implementation.

Summary Table:

| Factor | Impact on Energy Efficiency |

|---|---|

| Feedstock Quality | Clean, dry plastics like PE/PP yield high energy output; wet or contaminated plastics reduce efficiency. |

| Heat Integration | Using syngas to power the reactor minimizes external energy needs, boosting net energy balance. |

| Process Scale | Continuous-feed reactors are more efficient than batch systems due to stable operating temperatures. |

| Pre-processing | Sorting, shredding, and drying consume energy but are essential for optimal performance. |

Ready to optimize your plastic pyrolysis process for maximum energy efficiency? At KINTEK, we specialize in advanced lab equipment and consumables tailored for pyrolysis research and development. Whether you're focused on waste management, energy production, or creating a circular economy, our solutions help you achieve a positive net energy balance with reliable, high-performance technology. Contact us today to discuss how we can support your laboratory's specific needs and drive your projects toward success!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How do you clean a tube furnace tube? A Step-by-Step Guide to Safe and Effective Cleaning

- What are the advantages of using an alumina liner in a tube furnace for biomass combustion corrosion simulations?

- What factors influence the general design of a tube furnace? Match Your Process with the Perfect System

- What is the pressure on a tube furnace? Essential Safety Limits for Your Lab

- Why is an Alumina Ceramic Tube Support Necessary for 1100°C Experiments? Ensure Data Accuracy and Chemical Inertness