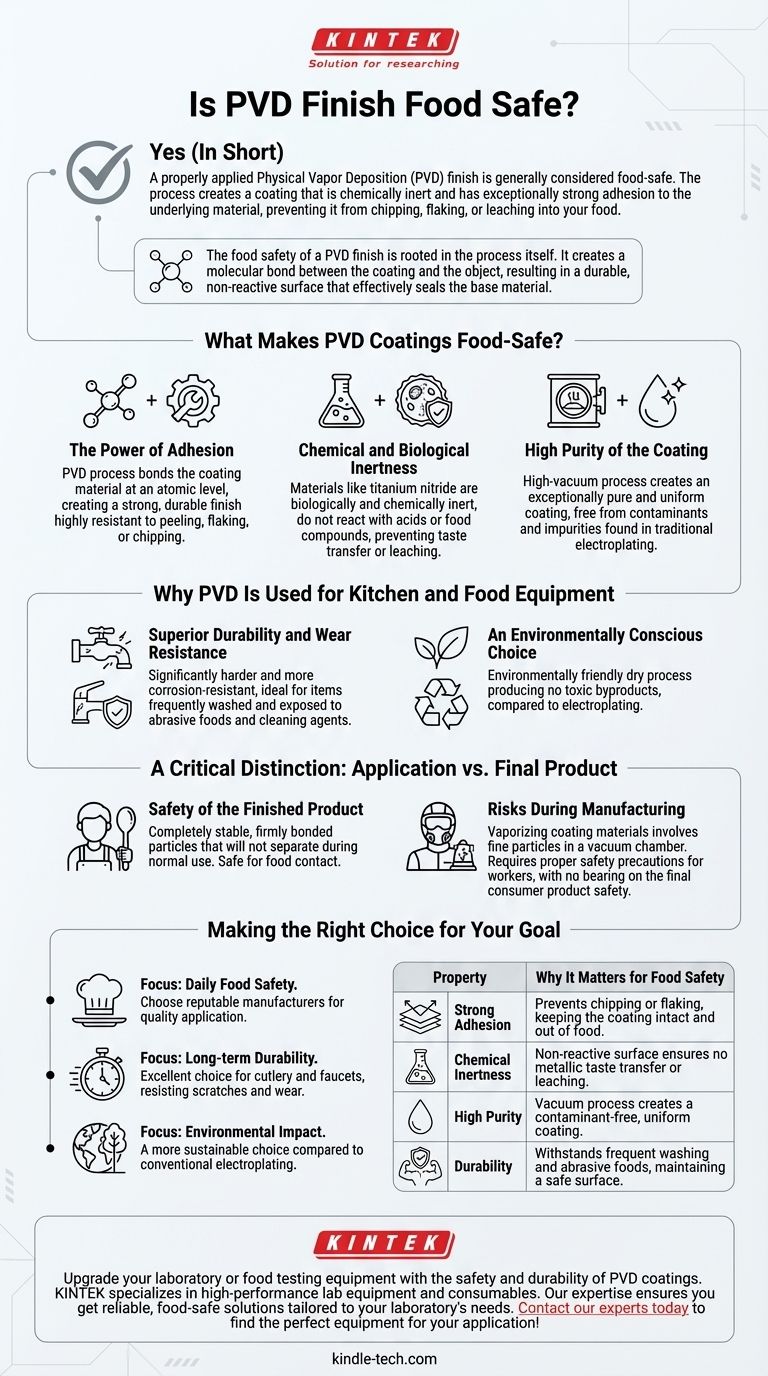

In short, yes. A properly applied Physical Vapor Deposition (PVD) finish is generally considered food-safe. The process creates a coating that is chemically inert and has exceptionally strong adhesion to the underlying material, preventing it from chipping, flaking, or leaching into your food.

The food safety of a PVD finish is rooted in the process itself. It creates a molecular bond between the coating and the object, resulting in a durable, non-reactive surface that effectively seals the base material.

What Makes PVD Coatings Food-Safe?

The safety of PVD coatings for food applications stems from three core properties that are a direct result of the deposition process.

The Power of Adhesion

The PVD process doesn't just "paint" a layer onto a surface; it bonds the coating material at an atomic level.

This creates an incredibly strong and durable finish that is highly resistant to peeling, flaking, or chipping, even with the wear and tear of daily use. This ensures the coating stays on the product and out of your food.

Chemical and Biological Inertness

Most materials used for PVD coatings, such as titanium nitride, are biologically and chemically inert.

This means they do not react with acids or other compounds found in food. This non-reactive quality is crucial for preventing any metallic taste transfer or leaching of materials.

High Purity of the Coating

PVD is a high-vacuum process, which means it takes place in a controlled environment free from contaminants.

This results in an exceptionally pure and uniform coating. Unlike some traditional electroplating methods, there are no impurities or secondary substances that could pose a health risk.

Why PVD Is Used for Kitchen and Food Equipment

The properties that make PVD safe also make it an ideal choice for high-use items like cutlery, kitchen faucets, and commercial food equipment.

Superior Durability and Wear Resistance

PVD coatings are significantly harder and more corrosion-resistant than traditional finishes. This makes them ideal for items that are frequently washed and exposed to abrasive foods and cleaning agents.

The finish protects the product from scratches and discoloration, extending its functional and aesthetic life.

An Environmentally Conscious Choice

Compared to processes like electroplating, which involve harsh chemicals and produce hazardous waste, PVD is an environmentally friendly process.

It is a dry process that produces no toxic byproducts, aligning with modern standards for sustainable manufacturing.

A Critical Distinction: Application vs. Final Product

To fully understand the safety of PVD, it's essential to separate the manufacturing process from the finished good you use every day.

Safety of the Finished Product

Once the PVD coating is applied, it is completely stable and firmly bonded to the substrate. The particles are locked in place and will not become airborne or otherwise separate from the product during normal use.

This is why the final product you hold in your hand is considered safe for food contact.

Risks During Manufacturing

The PVD process itself involves vaporizing coating materials into tiny particles within a vacuum chamber. Inhaling these fine particles can pose health risks for workers.

For this reason, manufacturing facilities must use proper safety precautions and ventilation systems to protect personnel during the application phase. This risk is confined to the industrial setting and has no bearing on the safety of the final consumer product.

Making the Right Choice for Your Goal

When considering a PVD-coated product, your decision can be guided by your primary goal.

- If your primary focus is daily food safety: Choose products from reputable manufacturers who specialize in PVD-coated kitchenware, as the quality of the application is key to its performance and safety.

- If your primary focus is long-term durability: A PVD finish is an excellent choice for items like cutlery and faucets, as its exceptional hardness will resist scratches and wear far better than traditional coatings.

- If your primary focus is environmental impact: Opting for a PVD-coated product is a more sustainable choice compared to those made with conventional electroplating processes.

Ultimately, you can confidently trust a well-made PVD-coated product in your kitchen.

Summary Table:

| Property | Why It Matters for Food Safety |

|---|---|

| Strong Adhesion | Prevents chipping or flaking, keeping the coating intact and out of food. |

| Chemical Inertness | Non-reactive surface ensures no metallic taste transfer or leaching. |

| High Purity | Vacuum process creates a contaminant-free, uniform coating. |

| Durability | Withstands frequent washing and abrasive foods, maintaining a safe surface. |

Upgrade your laboratory or food testing equipment with the safety and durability of PVD coatings. KINTEK specializes in high-performance lab equipment and consumables. Our expertise ensures you get reliable, food-safe solutions tailored to your laboratory's needs. Contact our experts today to find the perfect equipment for your application!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells