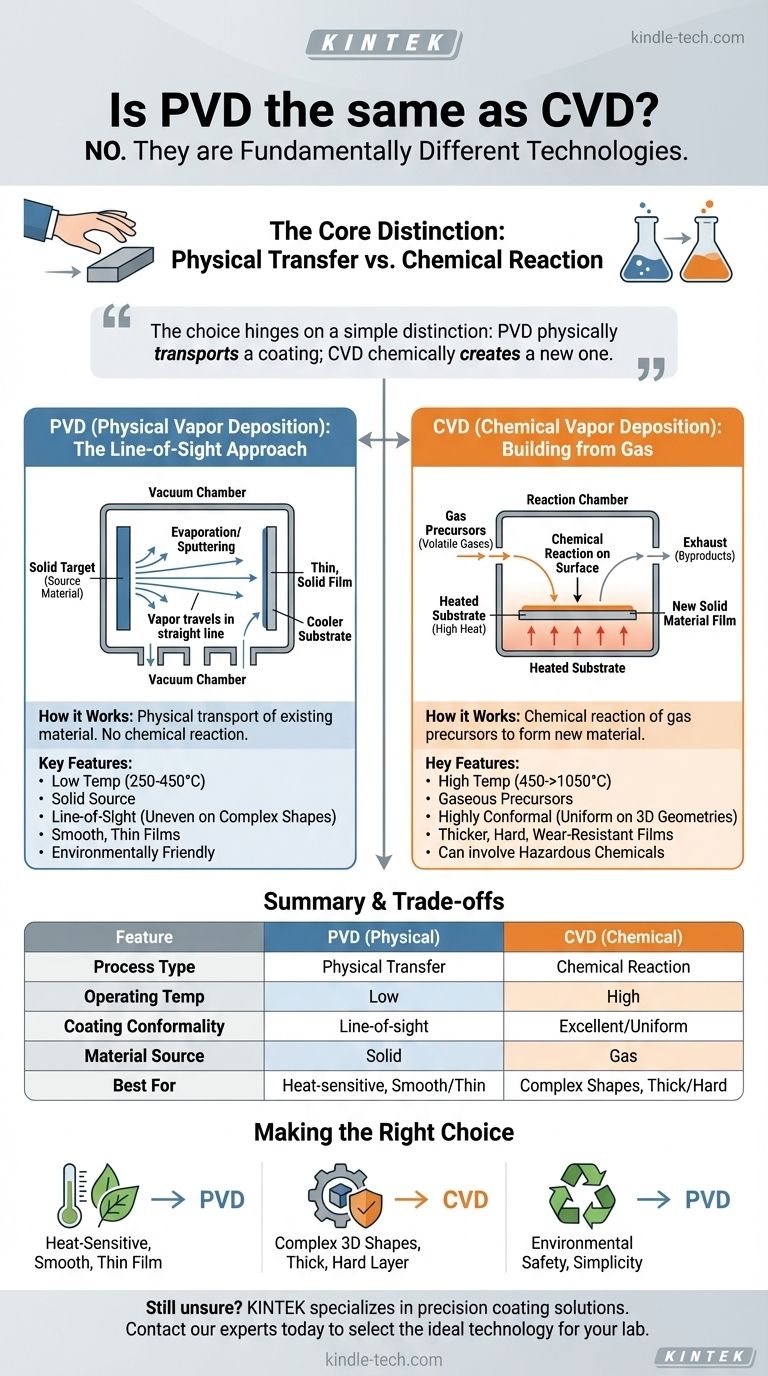

While often discussed together, PVD and CVD are fundamentally different technologies. No, they are not the same. Physical Vapor Deposition (PVD) is a physical process that transports an existing material from a source to a substrate, like spray painting on an atomic level. Chemical Vapor Deposition (CVD), in contrast, is a chemical process that uses gas precursors to create an entirely new material directly on the substrate's surface through a chemical reaction.

The choice between PVD and CVD hinges on a simple distinction: PVD physically transports a coating material onto a surface, while CVD chemically creates a new coating material directly on that surface. This core difference dictates the process temperature, coating properties, and ultimately, the right tool for the job.

The Core Distinction: A Physical Transfer vs. a Chemical Reaction

To choose the right method, you must first understand how their foundational mechanisms differ. One moves matter, and the other creates it.

How PVD Works: The Line-of-Sight Approach

In PVD, a solid source material (the "target") is placed in a vacuum chamber. This material is then vaporized through physical means, such as heating it until it evaporates or bombarding it with ions (a process called sputtering).

This vapor then travels in a straight line—a "line-of-sight" path—and condenses on the cooler substrate, forming a thin, solid film. No chemical reaction occurs; the deposited film is the same material as the source target.

How CVD Works: Building from Gas

CVD begins with introducing volatile precursor gases into a reaction chamber. These gases are not the final coating material itself but contain the chemical elements required to form it.

The substrate inside the chamber is heated to a very high temperature, which provides the energy needed to trigger a chemical reaction between the gases on the substrate's surface. This reaction forms a new, solid material that deposits as a film, and the leftover chemical byproducts are exhausted from the chamber.

Key Differences in Process and Outcome

The foundational difference between a physical and chemical process leads to vastly different operating parameters and coating characteristics.

Operating Temperature

PVD operates at relatively low temperatures, typically between 250°C and 450°C. This makes it suitable for a wide range of substrates, including some plastics and heat-treated steels that cannot tolerate high heat.

CVD is a high-temperature process, generally requiring 450°C to over 1050°C. This extreme heat limits its use to materials that are thermally stable and will not melt, warp, or lose their properties.

Coating Material Source

PVD uses a solid source material that is physically vaporized. This gives you precise control over the deposition of pure metals, alloys, and certain ceramic compounds.

CVD uses gaseous precursor materials. This allows for the creation of a very wide range of materials, including unique carbides, nitrides, and oxides that would be difficult to deposit with PVD.

Coating Conformality and Thickness

Because PVD is a line-of-sight process, it can struggle to evenly coat complex shapes with undercuts or internal surfaces. The coating will be thickest on the areas directly facing the source.

CVD, however, is a gas-based process where the reactive gases surround the substrate. This results in a highly conformal coating that uniformly covers even the most intricate and complex 3D geometries. CVD processes can also typically build up thicker films than PVD.

Film Properties and Smoothness

PVD processes are known for producing exceptionally smooth, dense, and thin films. The resulting coatings are often durable and possess excellent aesthetic or functional properties.

CVD films can be thicker and are prized for their extreme hardness and wear resistance. However, depending on the chemistry, they can sometimes be rougher than PVD coatings.

Understanding the Trade-offs

Neither technology is universally superior. The right choice is always a matter of balancing requirements against process limitations.

PVD: Precision at a Lower Temperature

The primary advantage of PVD is its low processing temperature, which protects the integrity of the substrate material.

PVD is also considered more environmentally friendly, as it is a physical process run in a vacuum and does not typically involve the toxic precursor gases or byproducts common in CVD. The main limitation is its line-of-sight nature, which reduces its effectiveness on complex shapes.

CVD: Durability and Versatility at a Cost

CVD's strength is its ability to produce highly conformal, uniform, and often extremely hard coatings on any surface the gas can reach.

The trade-off is the extreme heat, which significantly limits the types of materials you can coat. Furthermore, the process often involves hazardous chemicals and requires careful handling and disposal of byproducts.

Making the Right Choice for Your Application

Selecting the correct technology requires matching your primary goal to the strengths of the process.

- If your primary focus is coating heat-sensitive materials or achieving a very smooth, thin film: PVD is almost always the correct choice due to its lower operating temperature and direct deposition mechanism.

- If your primary focus is creating an exceptionally thick, hard, and uniform layer on complex 3D shapes: CVD's chemical, gas-based process provides superior conformality and is the preferred method, provided your substrate can withstand the heat.

- If your primary focus is environmental safety or process simplicity: PVD is generally considered the more environmentally friendly and operationally simpler process to manage.

Understanding this core physical-versus-chemical distinction empowers you to select the precise tool for your engineering challenge.

Summary Table:

| Feature | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Process Type | Physical transfer | Chemical reaction |

| Operating Temperature | 250°C - 450°C | 450°C - >1050°C |

| Coating Conformality | Line-of-sight (uneven on complex shapes) | Excellent (uniform on 3D geometries) |

| Material Source | Solid target | Gaseous precursors |

| Best For | Heat-sensitive substrates, smooth thin films | Complex shapes, thick hard coatings |

Still unsure whether PVD or CVD is right for your application? KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision coating solutions. Our experts can help you select the ideal technology to enhance durability, performance, and efficiency for your specific substrates and requirements. Contact us today for a personalized consultation and discover how our advanced coating systems can elevate your laboratory's capabilities!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the precursor gas in PECVD? The Key to Low-Temperature Thin Film Deposition

- What is the difference between thermal CVD and PECVD? Choose the Right Thin-Film Deposition Method

- What are the examples of CVD method? Discover the Versatile Applications of Chemical Vapor Deposition

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method

- What is the difference between CVD and PVD process? A Guide to Choosing the Right Coating Method