From a technical standpoint, pyrolysis has significant potential to be beneficial for the environment. When properly implemented, it transforms waste streams into valuable, low-carbon resources, but its net environmental impact is not guaranteed. The outcome is critically dependent on the source of the material being processed and the operational integrity of the system itself.

Pyrolysis is not inherently "good" or "bad" for the environment; it is a powerful tool. Its environmental benefit hinges entirely on its application—specifically, using legitimate waste as feedstock and rigorously controlling the process to prevent pollution.

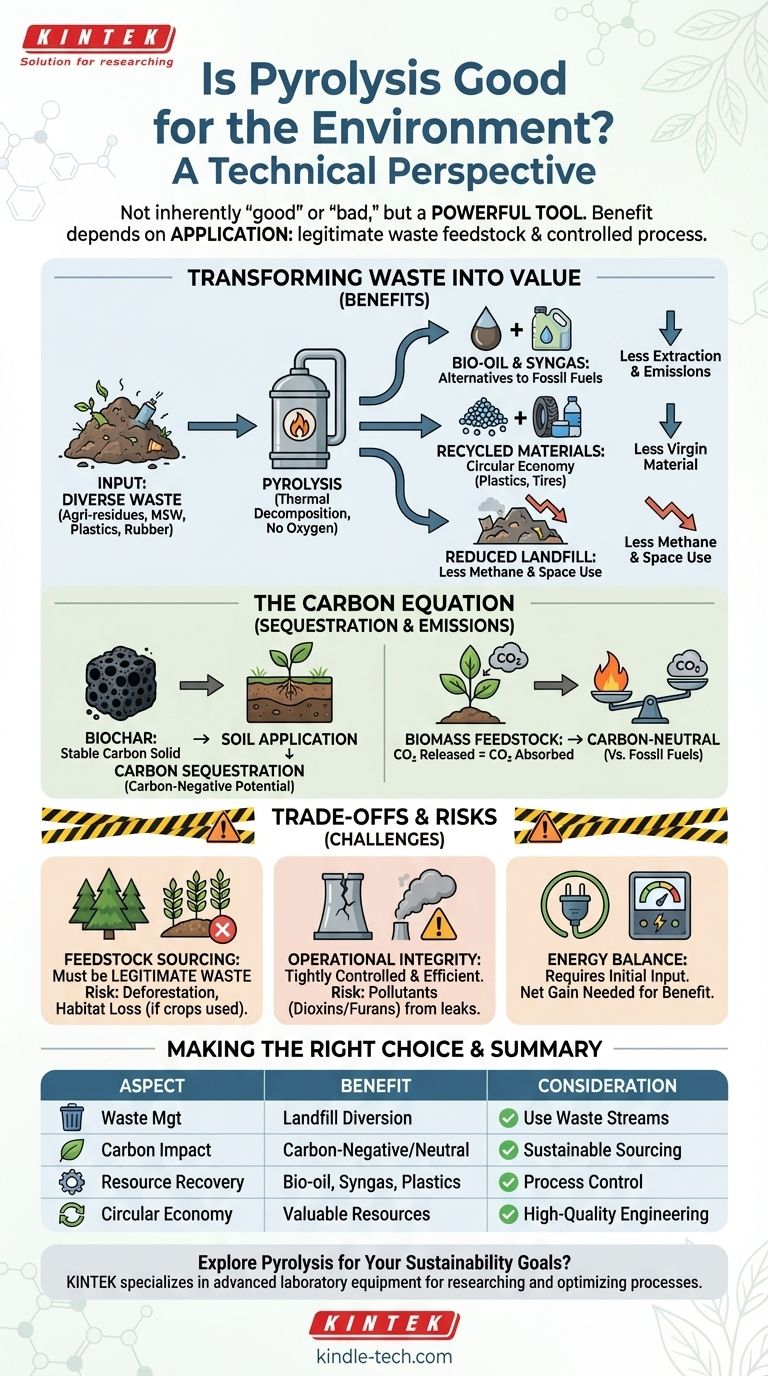

The Core Benefit: Transforming Waste into Value

Pyrolysis is fundamentally a thermal decomposition process that occurs in the absence of oxygen. Instead of burning waste, it breaks it down chemically, which is the source of its primary environmental advantages.

Reducing Landfill Burdens

Pyrolysis offers a direct alternative to sending waste to landfills. It can effectively process diverse organic materials, including agricultural residues, municipal solid waste, and even hard-to-recycle plastics and rubber.

This dramatically reduces the volume of waste requiring disposal, mitigating land use and the release of landfill gases like methane, a potent greenhouse gas.

Creating Alternatives to Fossil Fuels

The process yields several valuable outputs. The two most prominent energy products are bio-oil, a liquid that can be refined into transportation fuels, and syngas, a combustible gas.

These products serve as direct replacements for conventional fossil fuels, reducing our dependence on extracted crude oil and natural gas and lowering the associated carbon emissions.

Enabling a Circular Economy

Beyond energy, pyrolysis can recover valuable materials from waste. For example, it can break down mixed plastic waste into its basic chemical components, which can then be used to create new, virgin-quality plastics.

This closes the loop on material life cycles, reduces the need to extract virgin raw materials, and lessens the environmental impact associated with manufacturing.

The Carbon Equation: Sequestration and Emissions

One of the most compelling environmental arguments for pyrolysis relates directly to the global carbon cycle.

The Role of Biochar in Carbon Sequestration

A key co-product of pyrolyzing biomass is biochar, a stable, carbon-rich solid resembling charcoal. When added to soil, biochar does not easily decompose.

This process effectively locks carbon away for hundreds or even thousands of years. This makes biomass pyrolysis a rare technology with the potential to be carbon-negative, actively removing CO2 from the atmosphere.

Lowering Greenhouse Gas Emissions

When biomass is used as a feedstock, the process is considered largely carbon-neutral. The CO2 released when its fuels are burned is equivalent to the CO2 the original plant absorbed from the atmosphere.

Compared to the emissions from extracting and burning fossil fuels, this represents a significant reduction in net new greenhouse gases entering the atmosphere.

Understanding the Trade-offs and Risks

The potential benefits of pyrolysis are only realized under specific conditions. A poorly planned or executed project can negate the advantages and create new environmental problems.

The Critical Issue of Feedstock Sourcing

The single greatest risk is the source of the biomass. If dedicated crops are grown unsustainably to feed a pyrolysis plant, it can lead to deforestation, habitat loss, and competition with food production.

The environmental benefit is only clear when the feedstock is a legitimate waste product, such as agricultural residue, wood waste, or non-recyclable municipal solid waste.

The Risk of Inefficient Operations

A pyrolysis reactor must be well-engineered and tightly controlled. If the process is inefficient or allows oxygen to leak in, it can produce harmful pollutants, including dioxins and furans.

The technology is not a magic box; its clean operation depends on high-quality engineering and constant monitoring to ensure complete and clean decomposition.

The Process is Energy-Efficient, Not Energy-Free

While pyrolysis is highly efficient, often using its own syngas output to power the heating process, it still requires a significant initial energy input to reach operating temperature. The overall energy balance must be positive to deliver a net environmental gain.

Making the Right Choice for Your Goal

To determine if pyrolysis is the right solution, you must first define your primary environmental objective.

- If your primary focus is waste management: Pyrolysis is an exceptional tool for diverting a wide range of organic and plastic waste from landfills, reducing land use and methane emissions.

- If your primary focus is climate change mitigation: The combination of displacing fossil fuels and creating biochar for carbon sequestration makes biomass pyrolysis a uniquely powerful strategy.

- If your primary focus is resource circularity: Pyrolysis is one of the few technologies capable of chemically recycling mixed plastics and tires back into valuable raw materials for industry.

Ultimately, the environmental value of pyrolysis is unlocked not by the technology alone, but by the responsible and intentional application of it.

Summary Table:

| Environmental Aspect | Potential Benefit of Pyrolysis | Key Consideration |

|---|---|---|

| Waste Management | Diverts waste from landfills, reduces methane emissions | Must use legitimate waste streams as feedstock |

| Carbon Impact | Can be carbon-neutral (biomass) or carbon-negative (with biochar) | Avoids deforestation; relies on sustainable sourcing |

| Resource Recovery | Creates bio-oil, syngas, and recycles plastics | Process efficiency and pollution control are critical |

| Circular Economy | Turns waste into valuable resources, reducing virgin material use | Requires high-quality engineering and operational control |

Ready to explore how pyrolysis technology can advance your sustainability and waste management goals? KINTEK specializes in advanced laboratory equipment and consumables for researching and optimizing pyrolysis processes. Whether you're developing new biochar applications, analyzing syngas yields, or testing feedstock efficiency, our precise and reliable tools are designed to support your innovation. Contact our experts today to discuss how we can equip your lab for success in the circular economy.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- What is the optimum temperature for pyrolysis? Target Your Desired Biochar, Bio-oil, or Syngas

- What is the composition of pyrolysis oil from plastic waste? Unlocking the Potential of Chemical Recycling

- What equipment is used for calcination? Choosing the Right System for Your Process

- What is the co-pyrolysis method? A Strategic Approach to Waste Valorization & Bio-Oil Upgrading

- What are the negative effects of plastic pyrolysis? The Hidden Environmental and Health Risks

- What are the different temperatures of pyrolysis? A Guide to Optimizing Biochar, Bio-Oil, and Syngas Production

- What is the heat required for pyrolysis? Mastering Energy Input for Optimal Biochar, Bio-Oil, or Syngas

- What is the heat required for calcination? A Guide to Accurate Energy Calculations