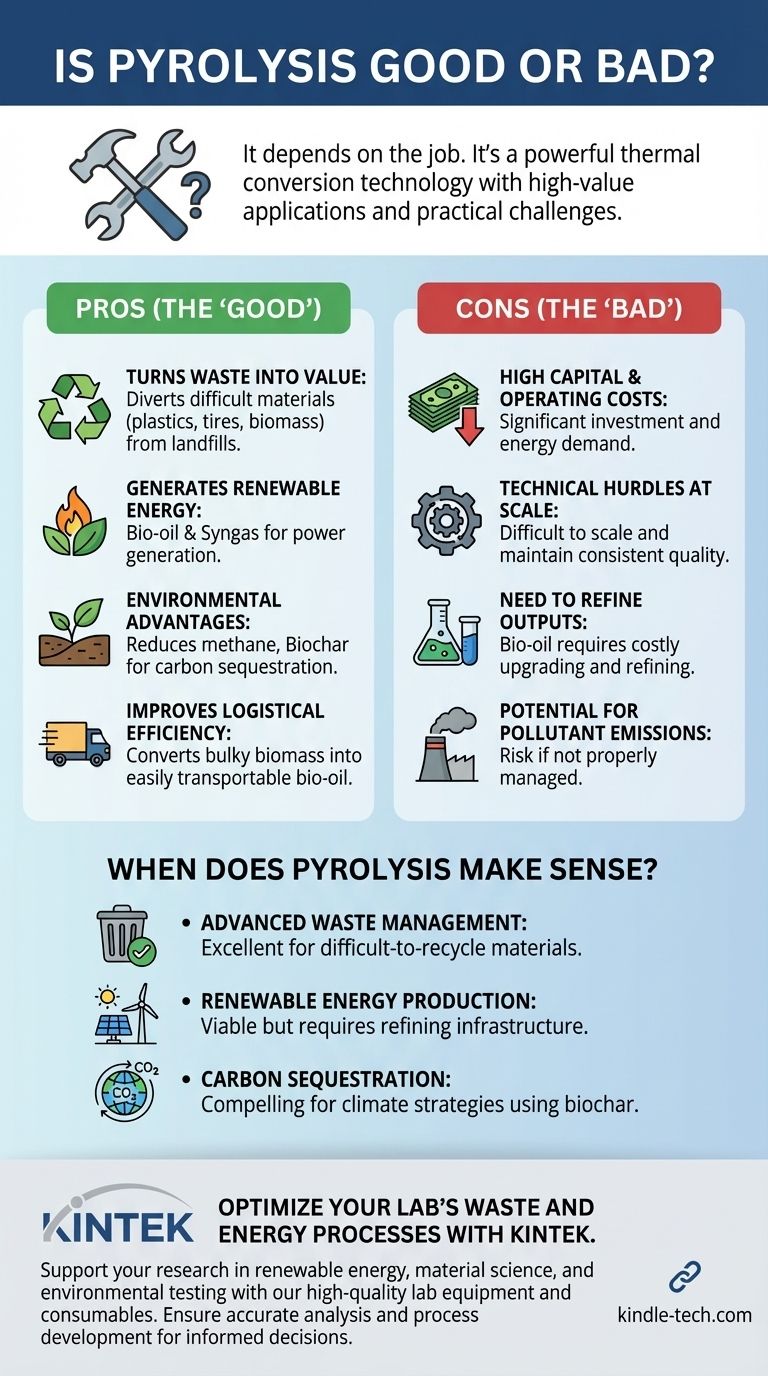

Asking if pyrolysis is good or bad is like asking if a hammer is a good or bad tool. The answer depends entirely on the job you need to do. Pyrolysis is not inherently one or the other; it is a powerful thermal conversion technology with a specific set of high-value applications and significant practical challenges that cannot be ignored.

The core value of pyrolysis is its ability to chemically decompose waste materials in the absence of oxygen, transforming them into valuable products like fuel and stable carbon. However, its effectiveness is a constant balance between this potential and the high costs, energy demands, and technical complexities required to operate it successfully.

What is Pyrolysis?

Pyrolysis is a process of thermal decomposition. In simple terms, it involves heating organic materials—such as biomass, plastics, or tires—to high temperatures in an environment with little to no oxygen.

It's Decomposition, Not Burning

Because there is no oxygen, the material doesn't combust or burn. Instead, the heat breaks down the complex chemical bonds, transforming the solid waste into three distinct and potentially valuable outputs.

The Three Core Products

The exact yield of each product depends on the feedstock and process conditions, but the outputs are always:

- Bio-oil (or Pyrolysis Oil): A liquid fuel that can be a substitute for some fossil fuels, though it often requires significant refining.

- Syngas (Synthesis Gas): A mixture of combustible gases, primarily hydrogen and carbon monoxide, which can be used to generate heat and power.

- Biochar: A stable, carbon-rich solid that can be used to improve soil quality and sequester carbon in the ground for long periods.

The Primary Benefits of Pyrolysis

When applied correctly, pyrolysis offers compelling environmental and economic advantages. It is best understood as a sophisticated waste valorization technology.

Turning Waste Streams into Value

Pyrolysis provides a powerful alternative to landfills. It can process difficult-to-recycle materials like mixed plastics, used tires, and agricultural waste, recovering value from streams that would otherwise be discarded.

Generating Renewable Energy

The bio-oil and syngas produced are energy carriers. They can be used on-site to power the pyrolysis process itself or be upgraded into higher-quality fuels and chemicals, reducing reliance on virgin fossil fuels.

Key Environmental Advantages

By diverting waste from landfills, pyrolysis reduces methane emissions, a potent greenhouse gas. Furthermore, the production of biochar creates a stable form of carbon that, when added to soil, effectively locks it away, acting as a form of carbon sequestration.

Improving Logistical Efficiency

Raw biomass is often bulky, wet, and difficult to transport. Pyrolysis can be performed at smaller, decentralized scales, converting that biomass into a more energy-dense and easily transportable liquid (bio-oil), which reduces handling costs.

Understanding the Trade-offs and Challenges

Despite its promise, pyrolysis is not a simple or universally applicable solution. The practical and economic hurdles are significant and must be central to any evaluation.

High Capital and Operating Costs

Pyrolysis plants require a significant upfront investment. The process also consumes a large amount of energy to reach and maintain the necessary high temperatures, which can impact the overall economic viability.

Technical Hurdles at Scale

While the chemistry is well-understood, scaling pyrolysis technology up to an industrial level that is both efficient and reliable presents considerable technical challenges. Maintaining consistent product quality from variable feedstock is a major difficulty.

The Need to Refine the Outputs

The raw bio-oil produced is not a "drop-in" replacement for transportation fuels like diesel or gasoline. It is acidic, unstable, and contains impurities, requiring costly and energy-intensive upgrading and refining before it can be widely used.

Potential for Pollutant Emissions

If not properly managed, the pyrolysis process can release pollutants into the atmosphere. A successful operation requires robust systems for cleaning the output gases and safely handling all byproducts.

When Does Pyrolysis Make Sense?

The decision to use pyrolysis should be based on a clear-eyed assessment of its strengths against your specific goals. It is a specialized tool, not a silver bullet.

- If your primary focus is advanced waste management: Pyrolysis is an excellent option for materials that are not easily recycled, as it reduces landfill volume while recovering energy and material value.

- If your primary focus is renewable energy production: It is a viable pathway, but you must account for the significant downstream costs and infrastructure needed to refine the bio-oil into a usable fuel.

- If your primary focus is carbon sequestration: The ability to create stable biochar makes pyrolysis a highly compelling technology for long-term climate strategies aimed at drawing down atmospheric carbon.

Ultimately, the value of pyrolysis is unlocked when the right feedstock is matched with the right economic conditions and technical expertise.

Summary Table:

| Aspect | Pros (The 'Good') | Cons (The 'Bad') |

|---|---|---|

| Waste Management | Diverts difficult-to-recycle waste from landfills | High capital and operating costs |

| Energy Production | Generates renewable bio-oil and syngas | Bio-oil requires costly refining before use |

| Environmental Impact | Reduces methane emissions; biochar sequesters carbon | Risk of pollutant emissions if not managed properly |

| Economic Viability | Creates value from waste streams | Technically complex to scale reliably |

Optimize Your Lab's Waste and Energy Processes with KINTEK

As you evaluate advanced technologies like pyrolysis for your research or operations, having the right lab equipment is crucial for accurate analysis and process development. KINTEK specializes in providing high-quality lab equipment and consumables to support your work in renewable energy, material science, and environmental testing.

Whether you're characterizing feedstocks, analyzing bio-oil, or testing biochar properties, our reliable equipment helps you gather the precise data needed to make informed decisions.

Let us help you equip your lab for success. Contact our experts today to discuss your specific needs and discover how KINTEK can be your trusted partner in laboratory innovation.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time