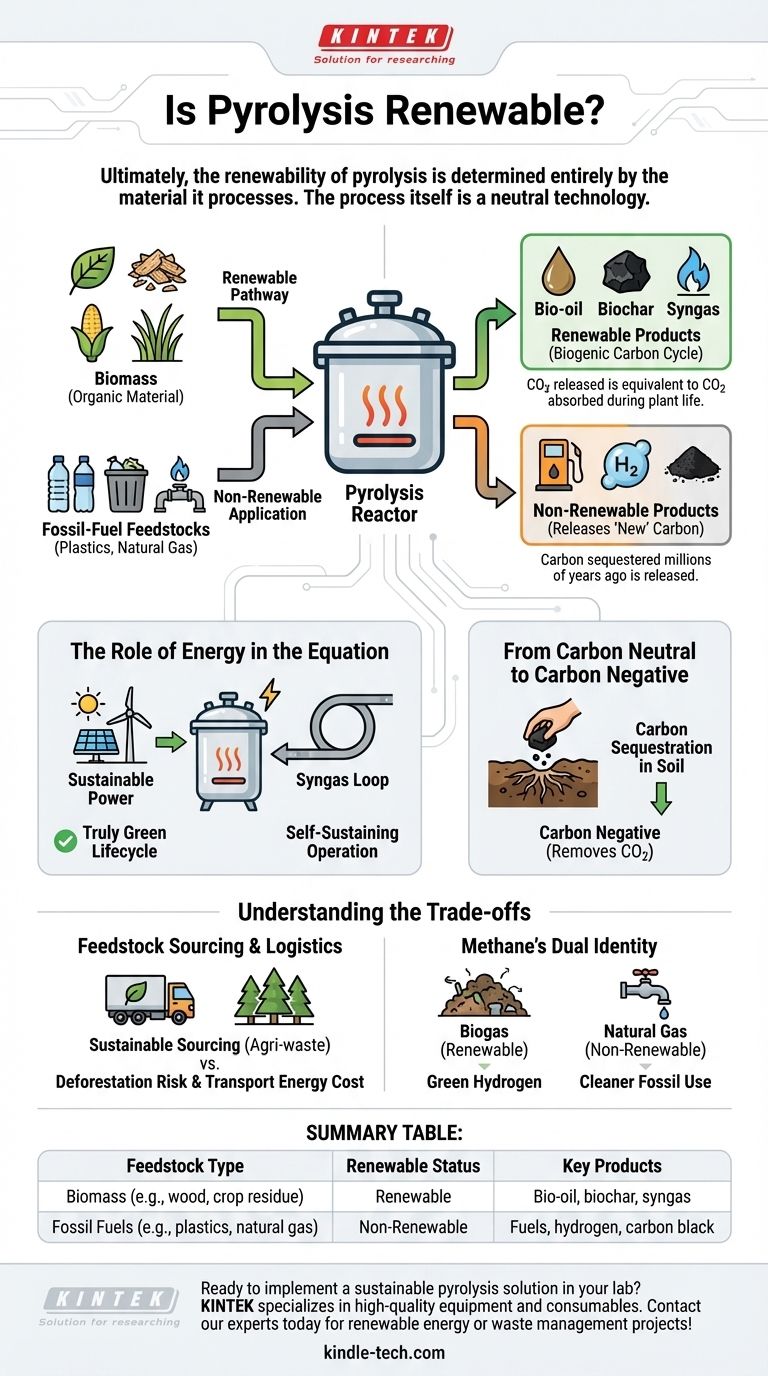

Ultimately, the renewability of pyrolysis is determined entirely by the material it processes. While the process itself is a neutral technology, it is considered renewable when it converts biomass—like wood or crop residue—into energy. It is not renewable when it processes materials derived from fossil fuels, such as plastics or natural gas.

The core principle is simple: Pyrolysis is a conversion tool. Its "renewable" status is inherited directly from its feedstock. If the input is renewable, the energy products are considered renewable.

The Deciding Factor: What Are You Heating?

Pyrolysis is a thermochemical process that decomposes material at high temperatures in an oxygen-free environment. Think of it as a high-tech pressure cooker. The key to its environmental classification isn't the cooker itself, but what you put inside it.

The Renewable Pathway: Biomass Pyrolysis

When the feedstock is biomass—organic material like wood, corn stover, or perennial grasses—the process is a key component of a renewable energy system.

This is because biomass is part of the biogenic carbon cycle. The carbon dioxide released when its resulting bio-oil is used is equivalent to the CO2 the plant absorbed from the atmosphere during its life.

The primary products of biomass pyrolysis are bio-oil (a liquid biofuel), biochar (a charcoal-like solid), and syngas (a mixture of combustible gases). Up to 75% of the initial biomass can be converted into bio-oil.

The Non-Renewable Application: Fossil-Fuel Feedstocks

Pyrolysis is also widely used to break down materials derived from fossil fuels. This includes waste plastics and methane from natural gas.

While this is a highly valuable technology for waste reduction and producing hydrogen or other fuels, it is not a renewable process. The carbon in these materials was sequestered millions of years ago, and using the resulting fuel releases new carbon into the atmosphere.

The Role of Energy in the Equation

Beyond the feedstock, the energy used to power the pyrolysis reactor itself is a critical part of its overall sustainability profile.

Powering the Process Sustainably

The pyrolysis reaction requires significant heat, often around 500°C. For the entire lifecycle to be considered truly green, this energy should come from a clean source.

This can be achieved by using renewable electricity from solar or wind to power the heaters. In some systems, a portion of the syngas produced during pyrolysis is looped back to fuel the reactor, creating a self-sustaining operation.

From Carbon Neutral to Carbon Negative

Biomass pyrolysis has a unique potential to go beyond being carbon neutral. One of its main by-products, biochar, is a stable, solid form of carbon.

If this biochar is not burned but instead sequestered by adding it to soil, the process becomes carbon negative. It actively removes carbon dioxide from the atmosphere and locks it away for long periods, improving soil health as an added benefit.

Understanding the Trade-offs

Like any technology, pyrolysis is not a silver bullet. Its practical application involves important considerations and potential downsides that must be managed.

Feedstock Sourcing and Logistics

The sustainability of biomass pyrolysis hinges on the responsible sourcing of its feedstock. Using genuine agricultural waste or sustainably grown energy crops is ideal.

However, if demand leads to deforestation or the displacement of food crops, the process can have significant negative environmental consequences. Transporting bulky biomass to a central plant also carries an energy cost.

Methane's Dual Identity

Methane pyrolysis is an excellent example of the critical need for nuance. This process splits methane (CH4) into hydrogen gas and solid carbon, avoiding CO2 emissions.

If the feedstock is biogas from landfills or anaerobic digesters, the process is renewable. If the feedstock is natural gas, it is a cleaner way to use a fossil fuel, but it is not renewable.

How to Classify a Pyrolysis Project

To determine if a specific application of pyrolysis is renewable, you must ask the right questions about its inputs and outputs.

- If your primary focus is renewable energy generation: Ensure the project exclusively uses sustainably sourced biomass as its feedstock.

- If your primary focus is advanced waste management: Using pyrolysis for non-recyclable plastics is a powerful energy recovery tool, but it should be classified as a non-renewable, fossil-fuel-based process.

- If your primary focus is clean hydrogen production: Scrutinize the source of the methane; only pyrolysis of biogas or biomethane qualifies as a truly renewable "green hydrogen" pathway.

Ultimately, viewing pyrolysis as a versatile conversion platform, rather than a fuel source in itself, is the key to accurately assessing its environmental credentials.

Summary Table:

| Feedstock Type | Renewable Status | Key Products |

|---|---|---|

| Biomass (e.g., wood, crop residue) | Renewable | Bio-oil, biochar, syngas |

| Fossil Fuels (e.g., plastics, natural gas) | Non-Renewable | Fuels, hydrogen, carbon black |

Ready to implement a sustainable pyrolysis solution in your lab? KINTEK specializes in high-quality lab equipment and consumables for biomass and material testing. Whether you're researching bio-oil production or optimizing pyrolysis parameters, our reliable systems help you achieve accurate, repeatable results. Contact our experts today to discuss how we can support your renewable energy or waste management projects!

Visual Guide

Related Products

- Graphite Vacuum Continuous Graphitization Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- How does graphite react to heat? Unlocking Its Unique High-Temperature Strengths

- Is graphite good in high temperature? Unlocking Its Extreme Heat Potential

- What are the mechanical properties of graphite? Harnessing Rigidity and Managing Brittleness

- How is synthetic graphite manufactured? A Deep Dive into the High-Temperature Process

- What is the temperature resistance of graphite? Unlocking Its High-Temp Potential in Your Lab