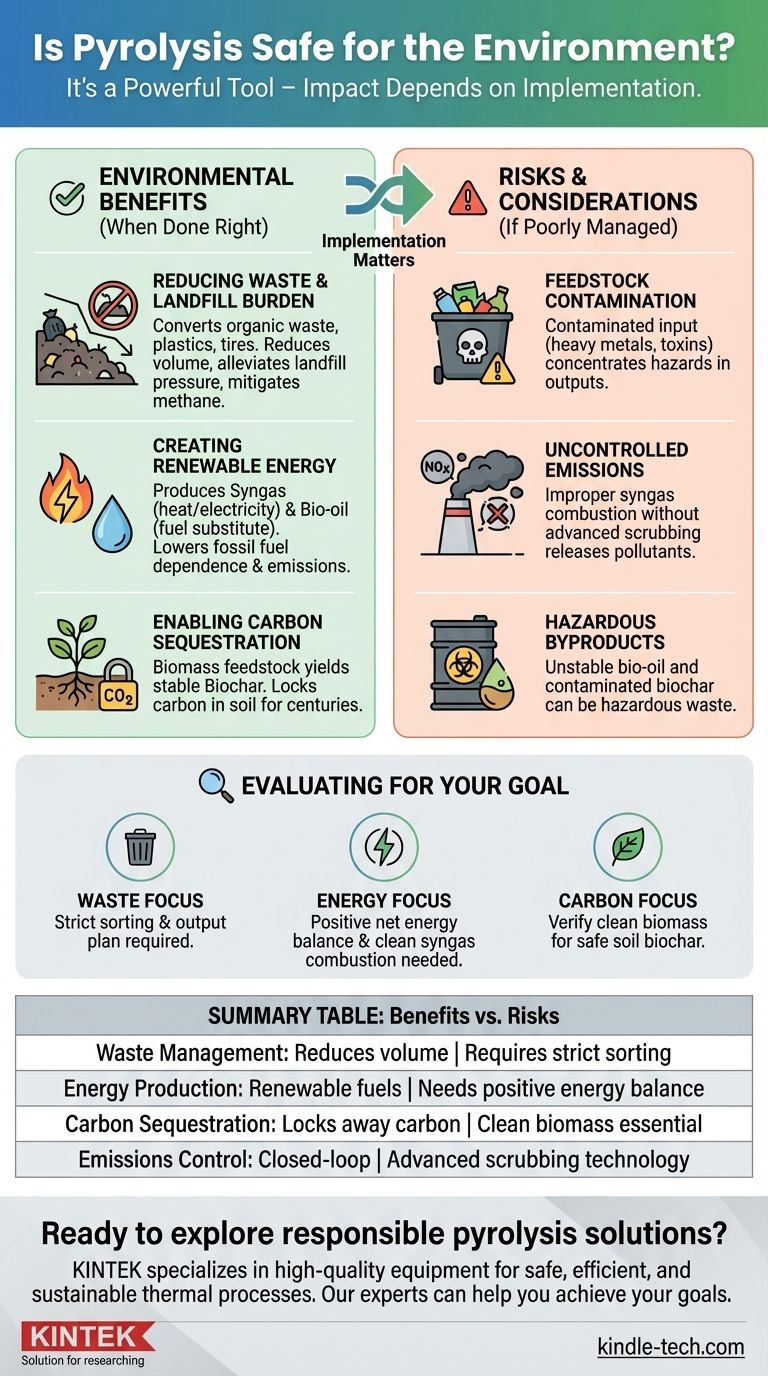

In the right context, pyrolysis represents a significant environmental improvement over traditional waste disposal methods like landfilling or incineration. It converts waste streams into valuable products, offers a pathway for renewable energy, and can even sequester carbon, but its safety is entirely dependent on the quality of the technology, the nature of the input material, and the management of its outputs.

Pyrolysis is not inherently "safe" or "unsafe." It is a powerful conversion tool whose environmental impact is dictated by how it is implemented. A well-designed, modern pyrolysis system processing clean feedstock is a net positive, while a poorly controlled system can create its own set of environmental hazards.

How Pyrolysis Contributes to Environmental Goals

Pyrolysis is fundamentally a process of thermal decomposition in the absence of oxygen. This distinction is what allows it to break down complex materials into simpler, more valuable substances rather than simply burning them.

Reducing Waste and Landfill Burden

Pyrolysis offers a powerful alternative to sending waste to landfills. It can effectively process organic materials like agricultural residues and wood waste, as well as more complex materials like plastics and tires that would otherwise persist in the environment for centuries.

This conversion reduces the volume of waste, alleviates pressure on landfill capacity, and mitigates the release of methane, a potent greenhouse gas produced by decomposing organic matter in landfills.

Creating Renewable Energy and Fuels

The process yields several useful products. Syngas, a mixture of hydrogen and carbon monoxide, can be combusted to generate heat and electricity. Bio-oil, a liquid fuel, can be refined and used as a substitute for conventional fossil fuels.

By creating energy from waste, pyrolysis reduces our dependence on fossil fuels, thereby decreasing the associated greenhouse gas emissions and pollution from their extraction and combustion.

Enabling Carbon Sequestration

When biomass is the feedstock, pyrolysis produces a stable, carbon-rich solid called biochar. Unlike the carbon in the original biomass, which would decompose and return to the atmosphere as CO₂, the carbon in biochar is locked in place.

When added to soil, biochar can remain stable for hundreds or thousands of years, representing a direct form of carbon sequestration. This makes it a valuable tool in strategies aimed at reducing atmospheric carbon levels.

Understanding the Trade-offs and Risks

The environmental benefits of pyrolysis are not automatic. Achieving them requires careful management of several critical risk factors.

The Critical Role of Feedstock

The principle of "garbage in, garbage out" applies directly to pyrolysis. The composition of the input material, or feedstock, determines the quality and safety of the outputs.

Processing clean, sorted biomass will yield clean biochar and fuels. However, if the feedstock is contaminated with substances like heavy metals, chlorine (from PVC plastics), or other toxins, these elements can become concentrated in the resulting char, oil, and gas streams, creating hazardous byproducts.

Managing Gaseous Emissions

While pyrolysis itself is a closed, low-oxygen process, the non-condensable syngas it produces must be handled correctly. If vented to the atmosphere, it represents a loss of energy and a source of pollution.

Proper implementation involves using the syngas as fuel on-site. The combustion of this gas must be carefully controlled at high temperatures with adequate emission-scrubbing technology to prevent the formation of pollutants like dioxins, furans, or nitrogen oxides (NOx).

Handling Liquid and Solid Byproducts

The liquid bio-oil can be acidic and unstable, requiring specialized handling and upgrading before it can be used as a widespread fuel. Similarly, if the feedstock was contaminated, the biochar can contain high concentrations of heavy metals, rendering it unsuitable for agricultural use and classifying it as hazardous waste.

Energy Balance and Efficiency

Pyrolysis requires a significant energy input to reach and maintain its high operating temperatures. For the process to be a net environmental benefit, it must generate more energy than it consumes. Modern systems achieve this by using the syngas produced during the process to power the operation itself, but poorly designed units can be net energy consumers.

Making the Right Evaluation for Your Goal

The environmental safety of pyrolysis is a function of system integrity and operational discipline. To determine if it is the right solution, you must evaluate it against your specific objective.

- If your primary focus is waste management: Pyrolysis is an excellent option for reducing landfill volume, but it requires strict feedstock sorting and a clear plan for safely managing all outputs.

- If your primary focus is energy production: It is a viable renewable energy source, provided the system is efficient enough to have a positive net energy balance and includes technology to cleanly combust the syngas.

- If your primary focus is carbon sequestration: Biomass pyrolysis is one of the most promising technologies for creating stable biochar, but you must verify the feedstock is clean to ensure the resulting biochar is safe for soil application.

Ultimately, pyrolysis is a sophisticated technology that, when implemented responsibly, is a powerful tool for building a more circular and sustainable economy.

Summary Table:

| Aspect | Potential Benefit | Key Risk / Consideration |

|---|---|---|

| Waste Management | Reduces landfill volume & methane emissions. | Requires strict feedstock sorting to avoid contamination. |

| Energy Production | Creates renewable fuels (syngas, bio-oil). | System must have a positive net energy balance. |

| Carbon Sequestration | Produces stable biochar to lock away carbon. | Biochar must be from clean biomass to be safe for soil. |

| Emissions Control | Closed-loop process prevents direct burning. | Syngas combustion requires advanced scrubbing technology. |

Ready to explore responsible pyrolysis solutions for your laboratory or operation? The right equipment is critical to achieving environmental benefits while mitigating risks. KINTEK specializes in high-quality lab equipment and consumables for advanced thermal processes. Our experts can help you select the right system to ensure efficient, safe, and sustainable outcomes for your specific waste or biomass conversion goals.

Contact our team today to discuss how we can support your sustainability initiatives with reliable technology.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs