Tyre pyrolysis is generally considered environmentally friendly due to its ability to convert waste tires into valuable resources like pyrolysis oil, carbon black, steel wire, and gas. This process reduces waste accumulation, provides a sustainable energy source, and minimizes harmful emissions when properly managed. The pyrolysis plant operates under controlled conditions, ensuring compliance with environmental standards, and the end products have significant market value. However, the environmental friendliness depends on the efficiency of the plant, the technology used, and the management of byproducts to prevent secondary pollution.

Key Points Explained:

-

Waste Reduction and Resource Recovery:

- Tyre pyrolysis significantly reduces the volume of waste tires, which are otherwise difficult to dispose of and often end up in landfills or illegal dumping sites.

- The process converts waste tires into valuable products such as pyrolysis oil, carbon black, steel wire, and gas. These products can be reused in various industries, promoting a circular economy.

-

Energy Efficiency and Sustainability:

- The pyrolysis oil produced has a high calorific value, making it suitable as a fuel source. This reduces reliance on fossil fuels and provides a renewable energy alternative.

- The process is energy-efficient, as the gas produced during pyrolysis can be recycled to heat the reactor, reducing external energy requirements.

-

Environmental Compliance and Safety:

- Modern pyrolysis plants are designed to meet stringent environmental standards, such as those set by the EU. They are equipped with advanced dust removal and deodorization systems to prevent air pollution.

- The water used in the condensing system is recycled, minimizing water waste and preventing contamination.

-

Byproduct Management:

- Carbon black, a byproduct of tyre pyrolysis, can be used in the manufacturing of new tires, rubber products, and as a pigment in inks and paints.

- Steel wire recovered from tires can be recycled in the steel industry, further reducing waste and resource consumption.

-

Technological Advancements:

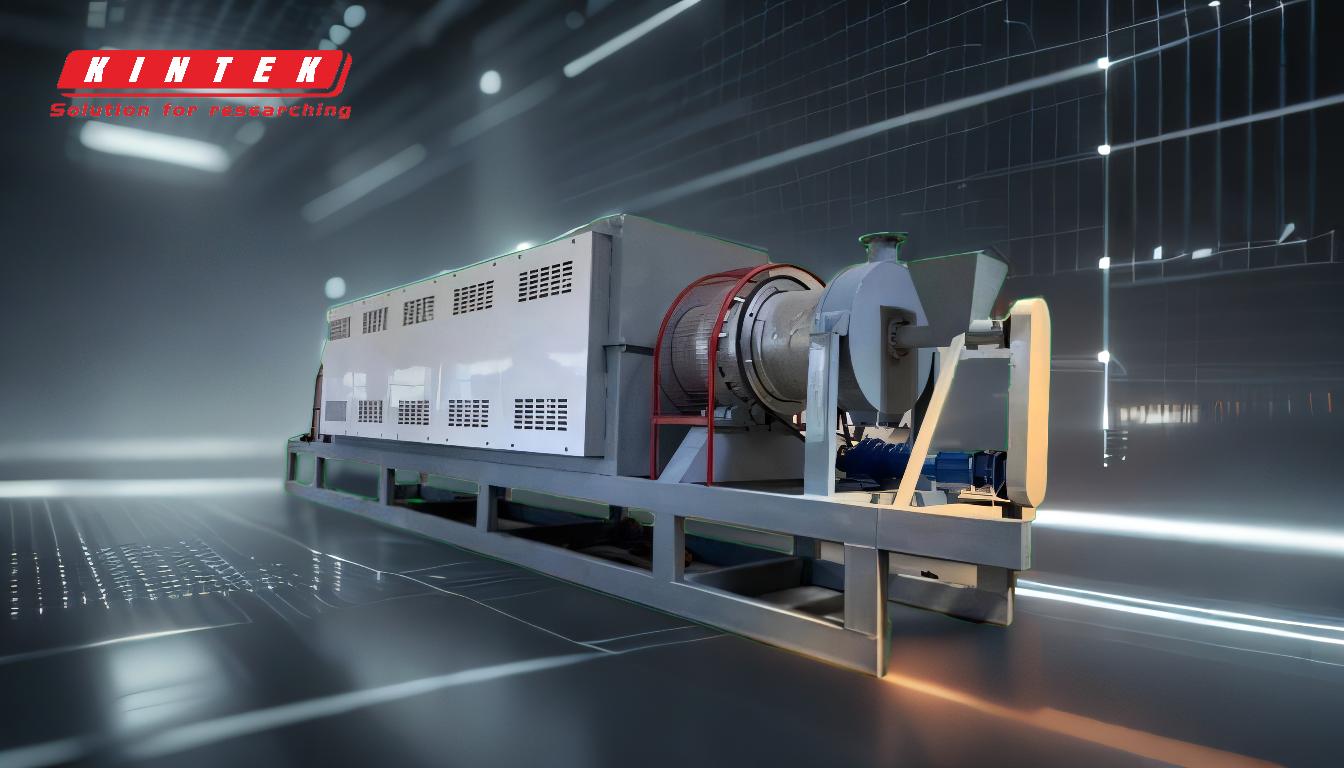

- Fully continuous pyrolysis plants, controlled by PLC systems, offer high efficiency, automation, and reduced labor costs. These advancements ensure consistent operation and minimize human error, enhancing environmental safety.

- The technology is scalable, allowing for the processing of large quantities of waste tires efficiently.

-

Global Environmental Impact:

- By converting waste tires into useful products, tyre pyrolysis contributes to reducing greenhouse gas emissions and fossil fuel dependency.

- The process aligns with global efforts to combat climate change by promoting sustainable waste management and clean energy production.

In conclusion, tyre pyrolysis is an environmentally friendly solution when implemented with proper technology and management practices. It addresses the critical issue of waste tire disposal while providing valuable resources and contributing to a sustainable future. For more information on the technology, you can explore pyrolysis plant.

Summary Table:

| Aspect | Benefits |

|---|---|

| Waste Reduction | Converts waste tires into pyrolysis oil, carbon black, steel wire, and gas. |

| Energy Efficiency | Pyrolysis oil serves as a renewable fuel, reducing fossil fuel dependency. |

| Environmental Compliance | Meets EU standards with dust removal, deodorization, and water recycling. |

| Byproduct Management | Carbon black and steel wire are reused in manufacturing, minimizing waste. |

| Technological Advancements | Fully continuous plants with PLC systems ensure efficiency and safety. |

| Global Impact | Reduces greenhouse gas emissions and supports sustainable energy production. |

Ready to adopt eco-friendly tyre pyrolysis? Contact us today to learn more!