Ball mill efficiency is determined by a precise interplay of operational settings and the inherent properties of the material being processed. In essence, factors you can control—such as rotational speed, the type and volume of grinding media, and the amount of material you feed—must be balanced against factors you cannot, like the hardness and initial size of the material itself. Understanding how to manipulate these variables is the key to optimizing your grinding operation.

Achieving peak efficiency is not about maximizing any single variable, but about finding the optimal balance between all contributing factors. This balance is dictated entirely by your end goal, whether that is achieving the finest possible particle size or maximizing the volume of material processed per hour.

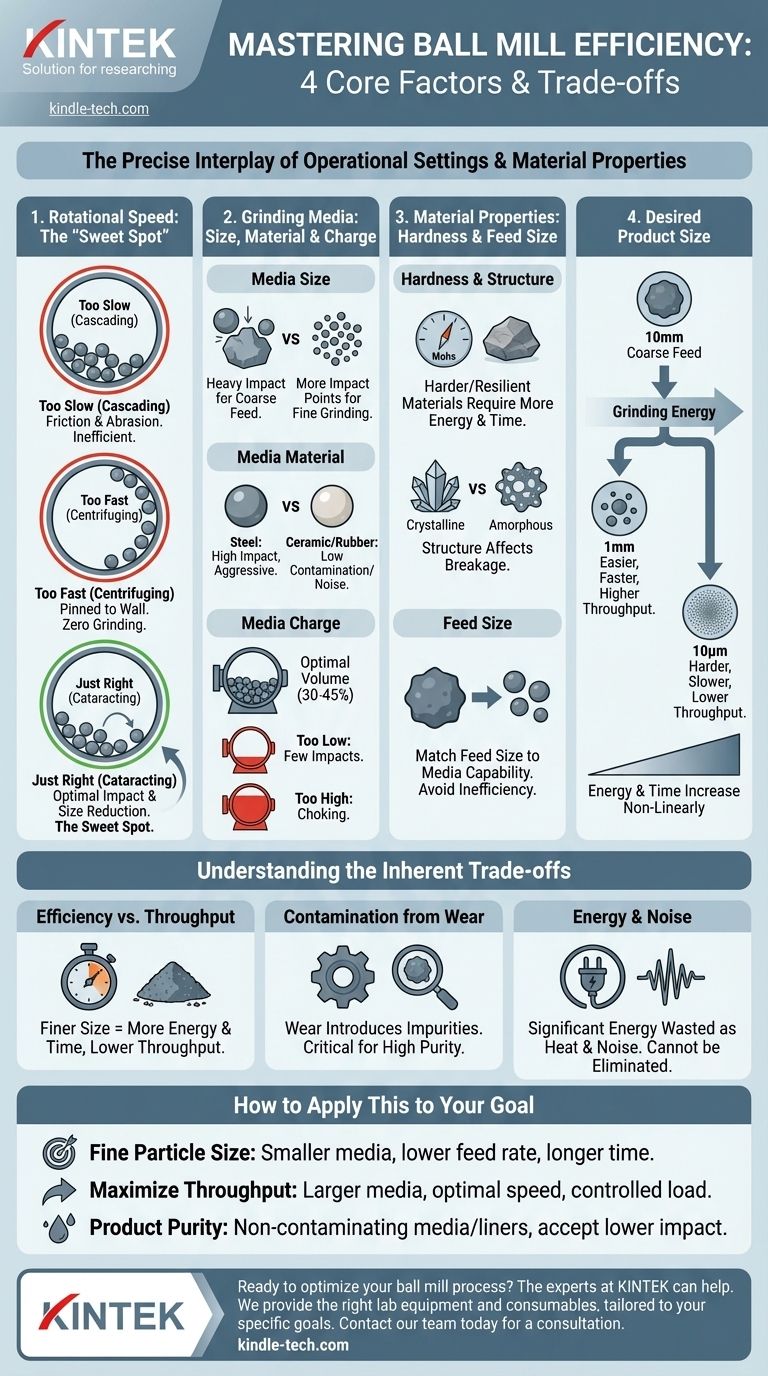

The Core Factors Influencing Mill Efficiency

The performance of a ball mill is a direct result of the mechanical energy transferred during grinding. Efficiency hinges on maximizing the energy used for particle size reduction while minimizing the energy wasted as heat, noise, and vibration. This is controlled by four key areas.

Rotational Speed: The "Sweet Spot" of Grinding

The speed of the mill's rotation is arguably the most critical operational parameter. It dictates the motion of the grinding media (the balls).

- Too Slow (Cascading): The balls simply tumble over one another, resulting in inefficient grinding based on friction and abrasion rather than impact.

- Too Fast (Centrifuging): The balls are pinned to the cylinder wall by centrifugal force and never fall, leading to almost zero grinding action.

- Just Right (Cataracting): At the optimal speed, the balls are carried up the cylinder wall and then thrown in an arc to impact the material at the bottom. This is the "sweet spot" that produces the most effective and efficient size reduction.

Grinding Media: Size, Material, and Charge

The grinding media are the engine of the mill. Their characteristics must be matched to the material and the desired outcome.

- Media Size: Larger, heavier balls provide greater impact force, which is necessary for breaking down large, coarse feed particles. Smaller balls create more impact points and a larger surface area, which is better for fine grinding of smaller particles.

- Media Material: Steel balls are common for high-impact, aggressive grinding. Ceramic or rubber balls are used when preventing metallic contamination is critical or when noise reduction is a priority, though they may grind less aggressively.

- Media Charge: This refers to the volume of the mill cylinder filled with grinding media, typically between 30-45%. Too low a charge results in fewer impacts and inefficient grinding. Too high a charge restricts the movement of the media and reduces the available space for the material, choking the grinding action.

Material Properties: Hardness and Feed Size

The nature of the material you are grinding establishes the baseline for the entire process.

- Hardness & Structure: The mechanical strength and internal structure of the material (e.g., crystalline vs. amorphous) directly determine how much energy is required to break it down. Harder, more resilient materials require more time and energy, lowering overall throughput efficiency.

- Feed Size: The size of the particles entering the mill must be appropriate for the size of the grinding media. Feeding particles that are too large for the media to effectively break is a primary cause of inefficiency.

Desired Product Size

Your target particle size is a crucial factor. The relationship between energy input and particle size reduction is not linear. Grinding a material from 10mm to 1mm is far easier than grinding it from 100 microns to 10 microns. Demanding an extremely fine product will inherently reduce the mill's efficiency when measured by throughput (tons per hour).

Understanding the Inherent Trade-offs

Optimizing a ball mill is a game of compromises. Improving one performance metric often comes at the expense of another. Being aware of these trade-offs is essential for realistic process design.

Efficiency vs. Throughput

Achieving an exceptionally fine particle size requires significant energy and time. This means that while your mill may be highly "efficient" at size reduction, its throughput (the amount of material processed over time) will be low. You must define which metric of efficiency matters most.

Contamination from Wear

The constant impact and abrasion inside a ball mill cause wear on both the grinding media and the cylinder's inner lining. This wear introduces small amounts of contamination into your product. While often negligible, this is a critical consideration for high-purity applications in the pharmaceutical or electronics industries.

Energy Consumption and Noise

Ball mills are energy-intensive machines. A significant portion of the electrical energy consumed is converted into heat and acoustic noise rather than productive grinding work. Optimizing operating parameters helps minimize this waste, but it cannot be eliminated.

How to Apply This to Your Goal

Your optimization strategy must be guided by your primary objective. There is no single "best" setup; there is only the best setup for your specific application.

- If your primary focus is achieving the finest particle size: Use smaller grinding media to increase contact points, reduce the material feed rate, and accept longer processing times.

- If your primary focus is maximizing throughput: Use larger media matched to a coarser feed, operate at the optimal cataracting speed, and carefully control the mill load to avoid choking.

- If your primary focus is product purity: Select grinding media and liners made of non-contaminating materials (like alumina or zirconia) and accept a potential reduction in grinding speed or impact force.

By systematically adjusting these variables, you can transform your ball mill from a simple machine into a precision instrument tailored to your exact needs.

Summary Table:

| Factor | Key Consideration | Impact on Efficiency |

|---|---|---|

| Rotational Speed | Find the 'cataracting' sweet spot for optimal impact. | Critical; too slow or fast drastically reduces grinding action. |

| Grinding Media | Match size/material to feed and desired product. | Determines impact force and grinding mechanism. |

| Material Properties | Hardness and initial feed size set the baseline. | Harder/finer grinding requires more energy, lowering throughput. |

| Media Charge | Maintain 30-45% volume for optimal media movement. | Too little or too much charge restricts grinding action. |

Ready to optimize your ball mill process for maximum efficiency and throughput? The experts at KINTEK can help. We specialize in providing the right lab equipment and consumables, including grinding media and mills, tailored to your specific material and particle size goals. Contact our team today for a consultation to enhance your grinding operation's performance and achieve your precise targets.

Visual Guide

Related Products

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

People Also Ask

- What role does a planetary ball mill play in the synthesis of Li2S-P2S5-SeS2? Powering Solid-State Electrolytes

- What is the function of a ball mill in synthesizing NMC622 and LLZ? Precision Grinding for High-Performance Batteries

- What is the primary function of a planetary ball mill? Mastering Argyrodite Solid Electrolyte Precursor Preparation

- Why is secondary ball milling necessary for sulfur cathodes? Master Solid-State Electrolyte Composite Preparation

- How does a planetary ball mill provide mechanical activation for scandium recovery? Maximize Your Leaching Efficiency

- What is the primary function of a planetary ball mill? Mastering SiCp/2024Al Composite Homogeneity

- What is the primary function of a high-energy ball mill? Master Silicon Anode Slurry Preparation

- What is the primary function of a planetary ball mill for Al2O3-TiC/CaF2 powders? Achieving Microstructural Homogeneity