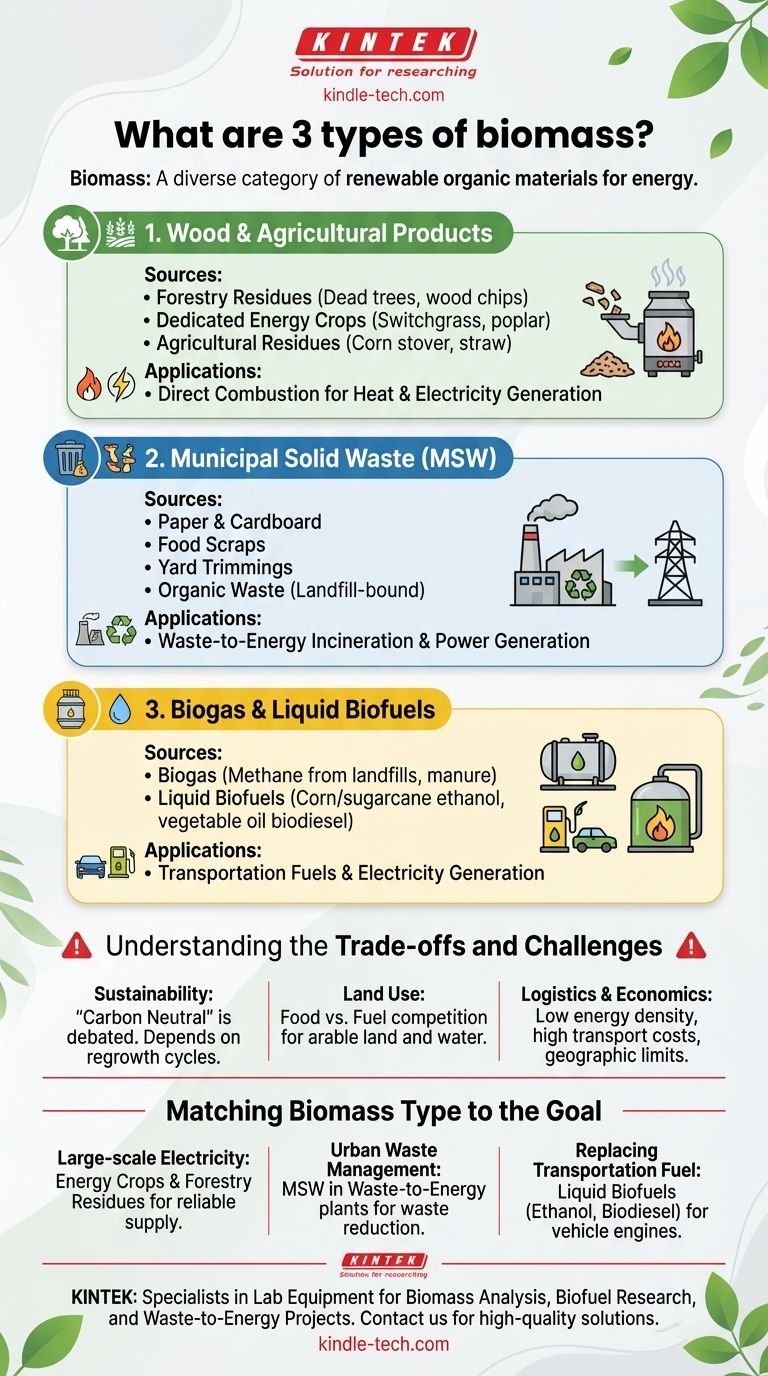

In practice, biomass is broadly categorized by its source and form. The three primary types are wood and agricultural products, solid waste from human activities, and captured biogas or processed liquid biofuels. Each category has distinct sources, conversion technologies, and applications, from direct combustion for heat to refinement into transportation fuels.

While often seen as a single renewable resource, "biomass" is a diverse category of organic materials. Understanding the fundamental differences between its types is the first step to evaluating its true potential and limitations as an energy source.

The Primary Categories of Biomass Fuel

Biomass is any organic matter—derived from plants or animals—that can be converted into energy. The key is to understand that the source of this material directly influences how it can be used.

1. Wood and Agricultural Products

This is the most traditional and widely used category of biomass. It consists of solid, raw organic material that is typically burned directly for heat or to generate electricity.

Sources in this category include forestry residues (such as dead trees, branches, and wood chips), dedicated energy crops (fast-growing plants like switchgrass and poplar), and agricultural crop residues (like corn stover, straw, and husks).

2. Municipal Solid Waste (MSW)

A significant portion of the waste generated by homes and businesses is organic and can be used as a fuel source. This is a key strategy in waste-to-energy systems.

The biomass portion of MSW includes paper and paperboard products, food scraps, yard trimmings, and other organic materials destined for a landfill. Using this waste for energy both reduces landfill volume and generates power.

3. Biogas and Liquid Biofuels

This category involves converting organic matter into a gas or liquid fuel rather than burning it in its solid form. This often requires a biological or chemical process.

Biogas is primarily methane captured from the anaerobic digestion (decomposition without oxygen) of organic materials like landfill waste, sewage, and animal manure.

Liquid biofuels are transportation fuels created from biomass. The most common are ethanol, an alcohol often made from fermenting corn or sugarcane, and biodiesel, produced from vegetable oils, animal fats, or recycled greases.

Understanding the Trade-offs and Challenges

While biomass is a renewable resource, its use is not without significant debate and practical challenges. Objectivity requires acknowledging these limitations.

The Question of Sustainability

The "carbon neutral" claim for biomass is heavily debated. While a new plant can reabsorb the carbon released by burning a previous one, this cycle can take decades, especially for forests.

If harvesting practices are not sustainable, biomass energy can contribute to deforestation and a net increase in atmospheric carbon over the short to medium term.

Land Use and "Food vs. Fuel"

A major criticism, particularly for biofuels like corn ethanol, is the competition for resources. Using arable land and water to grow energy crops can reduce the land available for food production.

This competition can lead to increased food prices and raise ethical questions about prioritizing fuel over food security, especially in a world with a growing population.

Logistical and Economic Hurdles

Unlike dense fossil fuels, solid biomass is often bulky, wet, and spread out geographically. The energy and cost required to collect, dry, and transport it to a power plant can be substantial.

This lower energy density means that biomass power is often only economically viable when the fuel source is very close to the processing facility, limiting its widespread applicability.

Matching the Biomass Type to the Goal

The right choice of biomass depends entirely on the intended outcome, whether it's powering a city, managing waste, or fueling vehicles.

- If your primary focus is large-scale, consistent electricity generation: Dedicated energy crops and well-managed forestry residues provide the most reliable and uniform fuel supply for power plants.

- If your primary focus is urban waste management and local power: Using Municipal Solid Waste (MSW) in a waste-to-energy plant or capturing biogas from landfills directly addresses waste reduction goals.

- If your primary focus is replacing petroleum in transportation: Liquid biofuels like ethanol and biodiesel are the only biomass types currently suitable for use in standard vehicle engines.

Ultimately, viewing biomass not as a single solution but as a portfolio of options is essential for harnessing its benefits effectively and responsibly.

Summary Table:

| Biomass Type | Primary Sources | Common Conversion Methods | Key Applications |

|---|---|---|---|

| Wood & Agricultural Products | Forestry residues, energy crops (e.g., switchgrass), crop waste (e.g., corn stover) | Direct combustion, gasification | Heat, electricity generation |

| Municipal Solid Waste (MSW) | Paper, food scraps, yard trimmings from households and businesses | Waste-to-energy incineration, landfill gas capture | Electricity generation, waste reduction |

| Biogas & Liquid Biofuels | Landfill gas, animal manure, vegetable oils, corn/sugarcane | Anaerobic digestion, fermentation, transesterification | Transportation fuels (ethanol, biodiesel), electricity |

Ready to find the right biomass solution for your energy or laboratory needs?

KINTEK specializes in supplying high-quality lab equipment and consumables essential for biomass analysis, biofuel research, and waste-to-energy projects. Whether you are developing new energy crops, analyzing biofuel composition, or optimizing conversion processes, our reliable equipment helps you achieve accurate and efficient results.

Let our experts support your biomass innovation. Contact us today to discuss your specific requirements and discover how KINTEK can empower your laboratory's success.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Conductive Carbon Fiber Brush for Static Removal and Cleaning

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process