At its core, natural rubber sheet is prized across industries for its exceptional elasticity, resilience, and high resistance to tearing and abrasion. Its unique combination of physical properties makes it the material of choice for applications requiring dynamic performance, from the anti-vibration mounts in your car to the durable linings of industrial mining chutes.

Natural rubber's value proposition is simple: it offers unmatched mechanical strength and flexibility. However, its utility is defined as much by its limitations—specifically, its poor resistance to oils, ozone, and high temperatures—as it is by its strengths.

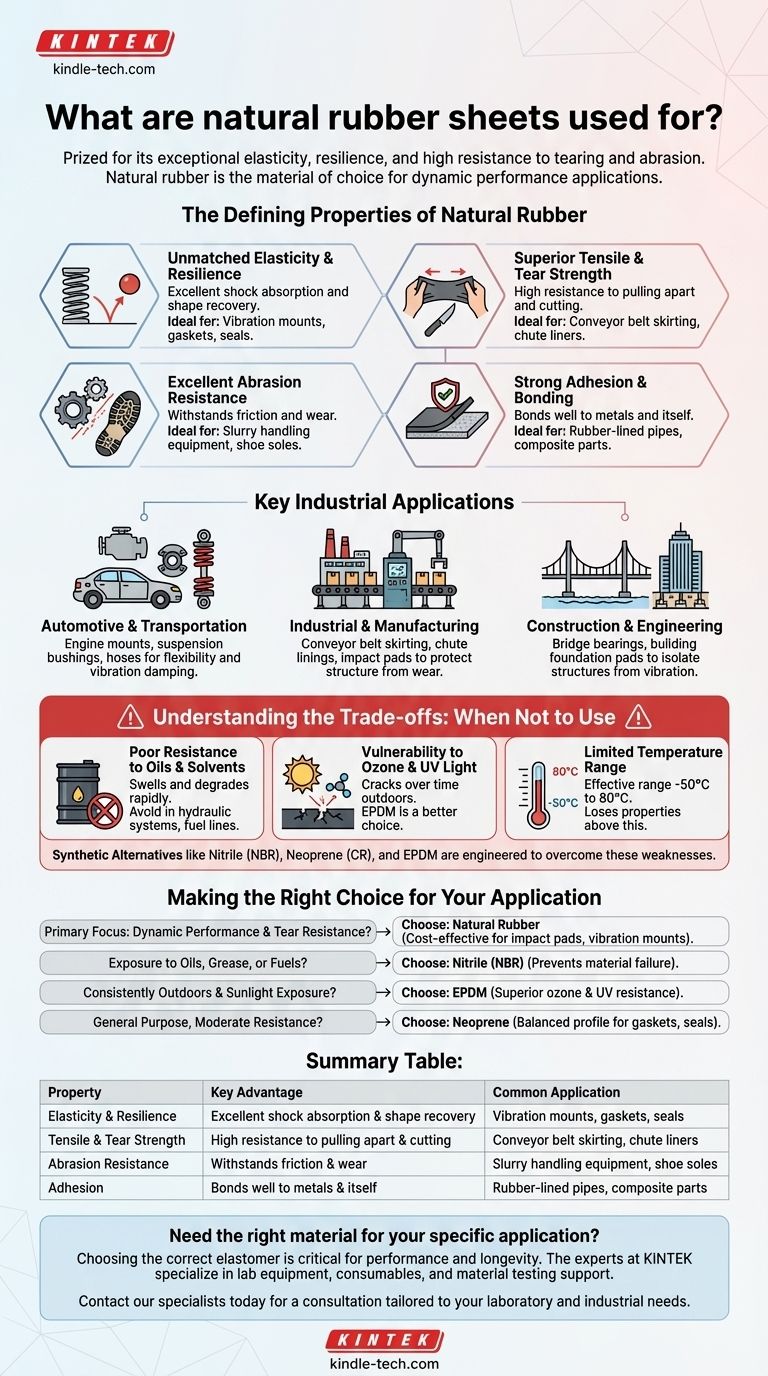

The Defining Properties of Natural Rubber

To understand where to use natural rubber, you must first understand its fundamental characteristics. These properties are the reason it has remained a staple material for over a century, even with the advent of countless synthetic alternatives.

Unmatched Elasticity and Resilience

Natural rubber has a remarkable ability to stretch to many times its original length and then return to its original shape without permanent distortion. This "snap-back" quality, known as high resilience, is critical for absorbing shock and vibration.

This makes it ideal for gaskets, seals, and shock absorbers that must deform and recover thousands of times during their service life.

Superior Tensile and Tear Strength

Tensile strength is a measure of the force required to pull a material apart. Tear strength measures its resistance to the growth of a cut or nick. Natural rubber excels in both categories.

This inherent toughness is why it's used for applications like conveyor belt skirting and chute liners, where it must withstand constant impact and the cutting action of sharp materials like rock and gravel.

Excellent Abrasion Resistance

Natural rubber holds up exceptionally well against friction and wear. It can endure scraping and rubbing without quickly degrading, a property known as abrasion resistance.

This is why it's a primary material for shoe soles, protective linings in slurry handling equipment, and the "skirts" on conveyor systems that guide abrasive materials.

Strong Adhesion and Bonding

A key manufacturing benefit of natural rubber is its natural tackiness. It readily bonds to itself and to metal substrates when properly prepared.

This property is crucial for creating composite parts, such as rubber-lined pipes or vibration mounts where the rubber must be permanently bonded to a metal fixture.

Key Industrial Applications

The properties above translate directly into a wide range of industrial and commercial uses.

Automotive and Transportation

The automotive industry is a massive consumer of natural rubber. It's used for engine mounts, suspension bushings, and various seals and hoses that require flexibility and vibration damping. While tires use a blend of natural and synthetic rubbers, natural rubber is a key component for its strength and heat-dissipation qualities.

Industrial and Manufacturing

In heavy industry, natural rubber sheet is a workhorse material. It's cut and fabricated into conveyor belt skirting, chute and hopper linings, and impact pads. Its purpose is to protect the underlying steel structure from abrasive wear and impact damage, extending the life of expensive equipment.

Construction and Engineering

In large-scale construction, natural rubber pads are used as bridge bearings and building foundation pads. These pads allow for slight thermal expansion and contraction and isolate structures from ground vibration, such as from nearby trains or seismic activity.

Understanding the Trade-offs: When Not to Use Natural Rubber

No material is perfect. Acknowledging natural rubber's weaknesses is just as important as knowing its strengths for proper material selection.

Poor Resistance to Oils and Solvents

This is natural rubber's most significant limitation. When exposed to petroleum-based oils, fuels, and many industrial solvents, it will swell, soften, and rapidly degrade. This makes it completely unsuitable for automotive fuel lines or seals in hydraulic systems.

Vulnerability to Ozone and UV Light

When exposed to direct sunlight (UV radiation) or ozone (often generated by electric motors), natural rubber will crack and become brittle over time. This phenomenon is known as "ozone cracking." For outdoor applications, it must be specially formulated with anti-ozonants or a more resistant material like EPDM should be used.

Limited Temperature Range

Natural rubber has a relatively narrow effective temperature range. It generally performs well between -50°C (-58°F) and 80°C (176°F). Above this upper limit, it can begin to lose its properties and revert to a soft, gummy state.

The Rise of Synthetic Alternatives

Materials like Nitrile (NBR), Neoprene (CR), and EPDM were specifically engineered to overcome natural rubber's weaknesses. Nitrile excels in oily environments, EPDM is superior for outdoor use, and Neoprene offers a balanced, general-purpose profile.

Making the Right Choice for Your Application

Selecting the right elastomer requires matching the demands of your environment to the properties of the material.

- If your primary focus is dynamic performance and tear resistance: Natural rubber is likely your best and most cost-effective choice for applications like impact pads and vibration mounts.

- If your application involves exposure to oils, grease, or fuels: You must use a synthetic alternative like Nitrile (NBR) rubber to prevent rapid material failure.

- If the part will be consistently outdoors and exposed to sunlight: EPDM rubber is the superior choice due to its exceptional resistance to ozone and UV degradation.

- If you need a jack-of-all-trades material with moderate resistance: Neoprene often provides a good balance of properties for general-purpose gaskets and seals where conditions are not extreme.

Understanding the unique strengths and critical weaknesses of natural rubber empowers you to select the right material with confidence.

Summary Table:

| Property | Key Advantage | Common Application |

|---|---|---|

| Elasticity & Resilience | Excellent shock absorption and shape recovery | Vibration mounts, gaskets, seals |

| Tensile & Tear Strength | High resistance to pulling apart and cutting | Conveyor belt skirting, chute liners |

| Abrasion Resistance | Withstands friction and wear | Slurry handling equipment, shoe soles |

| Adhesion | Bonds well to metals and itself | Rubber-lined pipes, composite parts |

Need the right material for your specific application?

Choosing the correct elastomer is critical for performance and longevity. The experts at KINTEK specialize in lab equipment and consumables, including material testing and selection support for industries relying on rubber components. We can help you validate material properties and ensure your project's success.

Contact our specialists today for a consultation tailored to your laboratory and industrial needs.

Visual Guide

Related Products

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Copper Foam

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Platinum Sheet Electrode for Laboratory and Industrial Applications

People Also Ask

- Why is platinum unreactive? The Atomic Secrets Behind Its Remarkable Stability

- How can you improve corrosion resistance? Extend Equipment Life with Proven Strategies

- What are the disadvantages of using metal? Understanding Corrosion, Weight, and Cost Challenges

- What is the difference between metallic and non-metallic coating? A Guide to Sacrificial vs. Barrier Protection

- What are the advantages disadvantages and uses of sheet metal? The Ultimate Guide to Material Selection