The primary challenges for biofuels are rooted in chemistry, economics, and logistics. Raw biofuels, particularly those derived from processes like pyrolysis, produce an unstable and corrosive bio-oil that is difficult to refine. This material has high oxygen content, which lowers its energy value and complicates its separation from the water produced during its creation, presenting significant technical and cost barriers to widespread adoption.

While biofuels offer a renewable alternative to fossil fuels, their path to viability is a constant balancing act. The very processes required to improve their quality and stability often reduce their yield and increase their cost, creating a fundamental trade-off that researchers and engineers are actively working to solve.

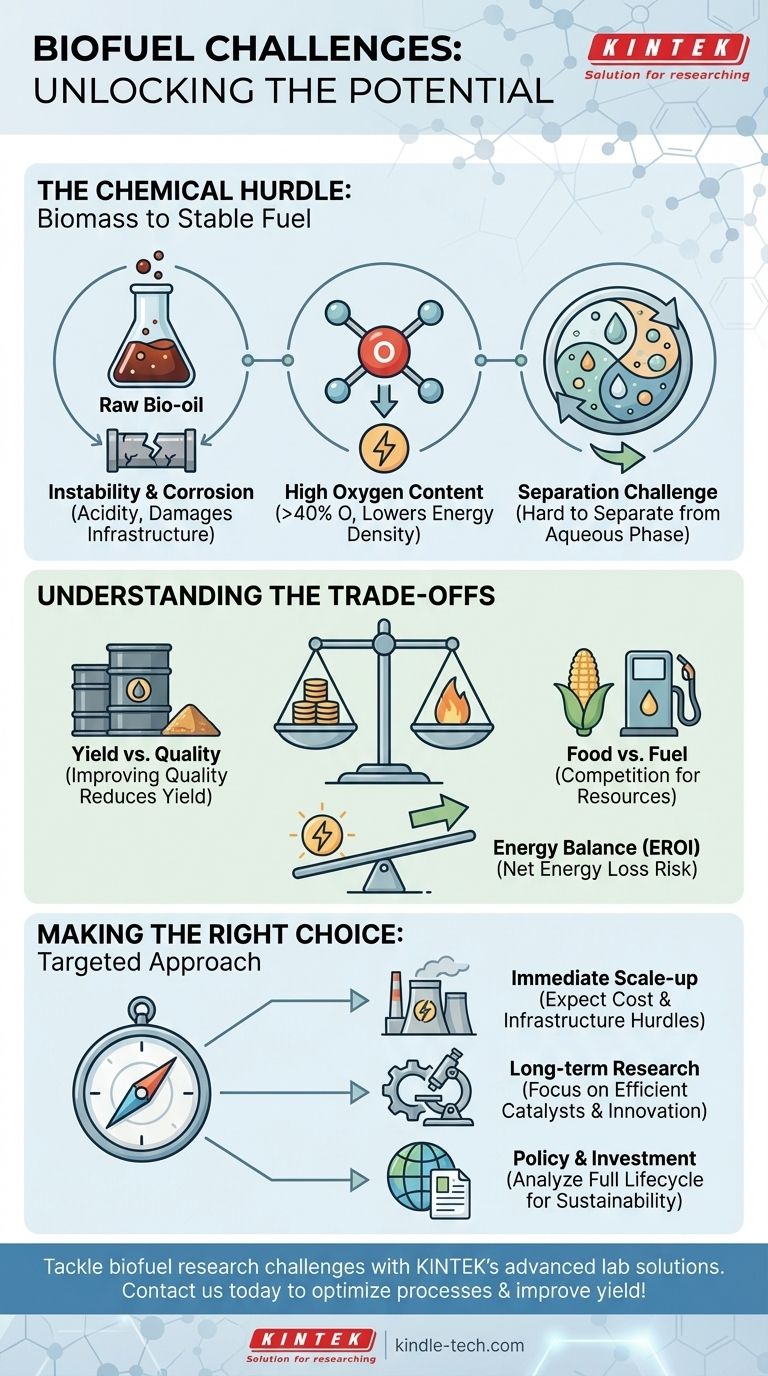

The Chemical Hurdle: From Biomass to Stable Fuel

The conversion of raw biomass into a usable liquid fuel is not a simple one-to-one process. The resulting bio-oil has inherent chemical properties that make it incompatible with existing infrastructure without significant, and often costly, upgrading.

The Problem of Instability and Corrosion

Raw bio-oil is highly acidic and chemically unstable. This corrosiveness means it can damage conventional pipelines, storage tanks, and engine components designed for petroleum-based fuels. Its instability also causes it to thicken and polymerize over time, turning into a tar-like substance that is difficult to handle.

The Oxygen Content Dilemma

Unlike crude oil, which is composed almost entirely of hydrocarbons, bio-oil contains a high percentage of oxygen (often over 40% by weight). This high oxygen content is a major drawback; it lowers the energy density of the fuel and contributes to its instability and corrosiveness. While processes exist to remove this oxygen (hydrodeoxygenation), they are energy-intensive and expensive.

The Separation Challenge

The process of creating bio-oil also produces a significant amount of water. Because of its chemical properties, the bio-oil does not easily separate from this aqueous phase. This emulsion-like mixture is difficult to process, and separating the valuable oil from the water adds another layer of complexity and cost to production.

Understanding the Trade-offs

Solving one problem in biofuel production often creates another. This landscape of competing priorities is central to understanding the slow pace of commercialization.

Yield vs. Quality

There is a direct trade-off between the quality of the bio-oil and the yield. For example, severe processing conditions designed to reduce the oxygen content to an acceptable level (e.g., below 25%) also tend to reduce the overall amount of usable carbon converted from the biomass. In essence, you sacrifice a portion of your final product to make the rest of it usable.

Food vs. Fuel

First-generation biofuels, like corn ethanol, created a direct conflict between using agricultural land for food production versus fuel production. This competition can drive up food prices and raise ethical questions about resource allocation. While newer generations of biofuels focus on non-food sources like algae or agricultural waste, they come with their own set of technical and cost challenges.

Energy Balance

A critical question for any fuel is its Energy Return on Investment (EROI). If the energy required to grow the feedstock, transport it, process it into biofuel, and refine it is greater than the energy it provides, the entire process is a net energy loss. Many biofuel pathways struggle to achieve a sufficiently positive energy balance to be economically viable without subsidies.

Making the Right Choice for Your Goal

Navigating biofuel viability requires understanding that the "best" approach depends entirely on the intended outcome.

- If your primary focus is large-scale, immediate energy replacement: Recognize that current-generation biofuels are not a simple "drop-in" solution and face significant cost and infrastructure hurdles.

- If your primary focus is long-term sustainable energy research: Concentrate on innovations that can break the yield-vs-quality trade-off, such as developing more efficient catalysts to remove oxygen without losing carbon.

- If your primary focus is policy or investment: Analyze the full lifecycle of a biofuel pathway—including land use, water consumption, and net energy balance—to ensure you are supporting a genuinely sustainable solution.

Ultimately, unlocking the full potential of biofuels depends on targeted innovation that addresses these fundamental chemical and economic challenges.

Summary Table:

| Challenge | Key Issue | Impact |

|---|---|---|

| Chemical Instability | High acidity and corrosiveness | Damages infrastructure, hard to store |

| High Oxygen Content | Over 40% oxygen by weight | Low energy density, unstable fuel |

| Yield vs. Quality | Improving quality reduces yield | Increases production costs |

| Food vs. Fuel | Competition for agricultural resources | Ethical and economic concerns |

| Energy Balance | Low Energy Return on Investment (EROI) | Economic viability without subsidies |

Ready to tackle your biofuel research challenges? KINTEK specializes in providing advanced lab equipment and consumables tailored for biofuel development. From pyrolysis reactors to analytical instruments, our solutions help you optimize processes, improve yield, and overcome chemical hurdles. Contact us today to enhance your renewable energy research with reliable, high-performance tools!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

People Also Ask

- How does the tip effect influence Al2O3 reinforcement in PCAS? Master Morphological Control for Stronger Composites

- What is an example of cold working and hot working? Control Metal Properties for Your Project

- What are the components of a rotavap? Master Gentle Evaporation for Sensitive Compounds

- What is the significance of a constant temperature drying oven in high-pressure CO2 reduction? Ensure Stable Results

- What is the method of spark plasma sintering? A High-Speed Powder Consolidation Technique

- What elements cannot be detected by XRF? Understanding the Limits of Light Element Analysis

- What materials can be processed with metal laser sintering or laser melting? High-performance alloys for demanding applications.

- Is pyrolysis oil a biofuel? Understanding Its Potential as a Renewable Energy Source