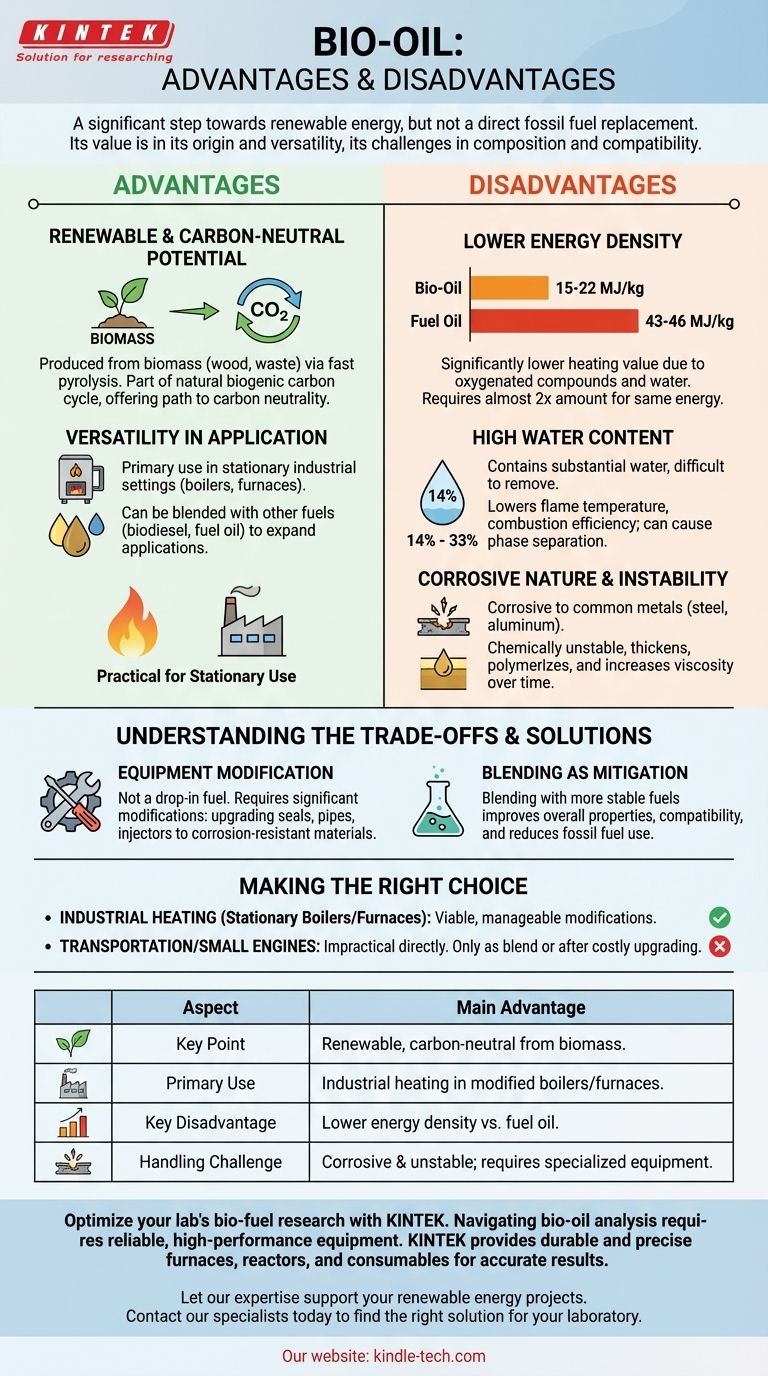

At its core, bio-oil represents a significant step toward renewable energy, but it is not a direct, drop-in replacement for conventional fossil fuels. Its main advantages are its renewable origin and versatility, while its primary disadvantages stem from its chemical composition, specifically a high water and oxygen content that leads to lower energy density and compatibility issues.

While bio-oil offers a renewable fuel source derived from biomass, its inherent properties—lower heating value, high water content, and corrosiveness—present significant technical challenges that currently limit its use to specific industrial applications or as a blend component.

The Primary Advantages of Bio-Oil

Bio-oil's value comes from its potential to reduce dependence on fossil fuels. Its benefits are rooted in its origin and adaptability.

Renewable and Carbon-Neutral Potential

Bio-oil is produced from biomass, such as wood or agricultural waste, through a process called fast pyrolysis. This means it is a renewable resource.

Because the carbon released during combustion was recently captured from the atmosphere by the source biomass, it is considered part of the natural biogenic carbon cycle, offering a path toward carbon-neutral energy.

Versatility in Application

Bio-oil is not limited to a single use. Its first and most practical applications are in stationary industrial settings, such as boilers and furnaces, where equipment can be adapted more easily.

Furthermore, bio-oil can potentially be blended with other fuels, like biodiesel or conventional fuel oil. This expands its range of applications and helps mitigate some of its inherent disadvantages.

Key Disadvantages and Technical Hurdles

The chemical nature of bio-oil creates several practical challenges that must be overcome for its widespread adoption. These are not minor issues; they fundamentally affect its performance and handling.

Lower Energy Density

Bio-oil has a higher heating value of 15–22 MJ/kg, which is significantly lower than that of conventional fuel oil (43–46 MJ/kg).

This is primarily due to the high concentration of oxygenated compounds and water. In practical terms, you need to burn almost twice as much bio-oil to generate the same amount of energy as fuel oil.

High Water Content

Bio-oil typically contains a substantial amount of water, often between 14% and 33% by weight. This water is not easily removed through simple methods like distillation.

High water content lowers the flame temperature and combustion efficiency. It can also cause the oil to separate into two phases, creating storage and handling problems.

Corrosive Nature and Instability

The presence of organic acids and other oxygenated compounds makes raw bio-oil corrosive to common construction metals like carbon steel and aluminum.

These same compounds make the oil chemically unstable. Over time, it can thicken, polymerize, and increase in viscosity, making it difficult to pump and atomize for combustion.

Understanding the Trade-offs: Equipment and Infrastructure

Using bio-oil is not a simple switch. It requires a clear understanding of the necessary adjustments to existing systems.

The Need for Equipment Modification

Due to its lower energy value and corrosive properties, bio-oil cannot be used as a drop-in fuel in most standard combustion engines or generators without significant modifications.

These changes often involve upgrading seals, pipes, and fuel injectors to corrosion-resistant materials and adjusting combustion systems to handle the different fuel properties.

Blending as a Mitigation Strategy

One of the most promising near-term strategies is blending bio-oil with more stable fuels. This approach can improve the overall properties of the fuel mixture, making it more compatible with existing infrastructure while still reducing fossil fuel consumption.

Making the Right Choice for Your Goal

The suitability of bio-oil depends entirely on the intended application and your tolerance for technical and economic trade-offs.

- If your primary focus is large-scale industrial heating: Bio-oil is a viable option for stationary boilers and furnaces, where equipment modifications are manageable and the fuel's lower energy density is less of a logistical constraint.

- If your primary focus is use in transportation or small engines: Direct use of raw bio-oil is impractical; it should only be considered as a blend component or after an intensive and costly upgrading process to improve its properties.

Ultimately, understanding bio-oil's role as a promising but challenging transitional fuel is key to leveraging its benefits effectively.

Summary Table:

| Aspect | Key Point |

|---|---|

| Main Advantage | Renewable, carbon-neutral potential from biomass (e.g., wood waste). |

| Primary Use | Industrial heating in modified boilers and furnaces. |

| Key Disadvantage | Lower energy density (15-22 MJ/kg) vs. fuel oil (43-46 MJ/kg). |

| Handling Challenge | Corrosive and unstable; requires specialized equipment. |

Optimize your lab's bio-fuel research with KINTEK.

Navigating the complexities of bio-oil analysis requires reliable, high-performance lab equipment. Whether you are characterizing fuel properties, testing blends, or developing upgrading processes, KINTEK provides the durable and precise furnaces, reactors, and consumables you need for accurate results.

Let our expertise in lab equipment support your renewable energy projects. Contact our specialists today to discuss your specific application and find the right solution for your laboratory.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Evaporation Boat for Organic Matter

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What is press and sintering? A Guide to Efficient, Net-Shape Manufacturing

- What is a gold sputtering target? A High-Purity Source for Precision Gold Coatings

- What is the major advantage of sputtering? Unmatched Material Versatility for High-Performance Thin Films

- What are the advantages of using HIP for tungsten-steel joints? Achieve 97%+ Density for Complex FGM Structures

- How do reaction vessels and heating systems influence Fe-Ni-B-P borided layers? Optimize Chemical Nickel Plating Success

- What is a target in a sputtering process? The Source of Your Thin Film Coating

- What are the risks of biomass boilers? Understanding the Environmental and Operational Trade-offs

- What are the four heat treatment methods to enhance the properties of steel? Master Annealing, Normalizing, Hardening, and Tempering