In short, the primary advantages of a rotary furnace are its ability to simultaneously mix and heat material, leading to superior temperature uniformity, highly efficient gas interaction, and consistent product quality. This dynamic processing environment makes it uniquely suited for applications involving powders, granules, and other free-flowing materials where exposing the entire surface area to heat and a controlled atmosphere is critical for the desired outcome.

The core value of a rotary furnace comes from its active, dynamic processing. Unlike static furnaces that heat material in a fixed position, the continuous rotation ensures every particle is treated equally, maximizing efficiency and product homogeneity.

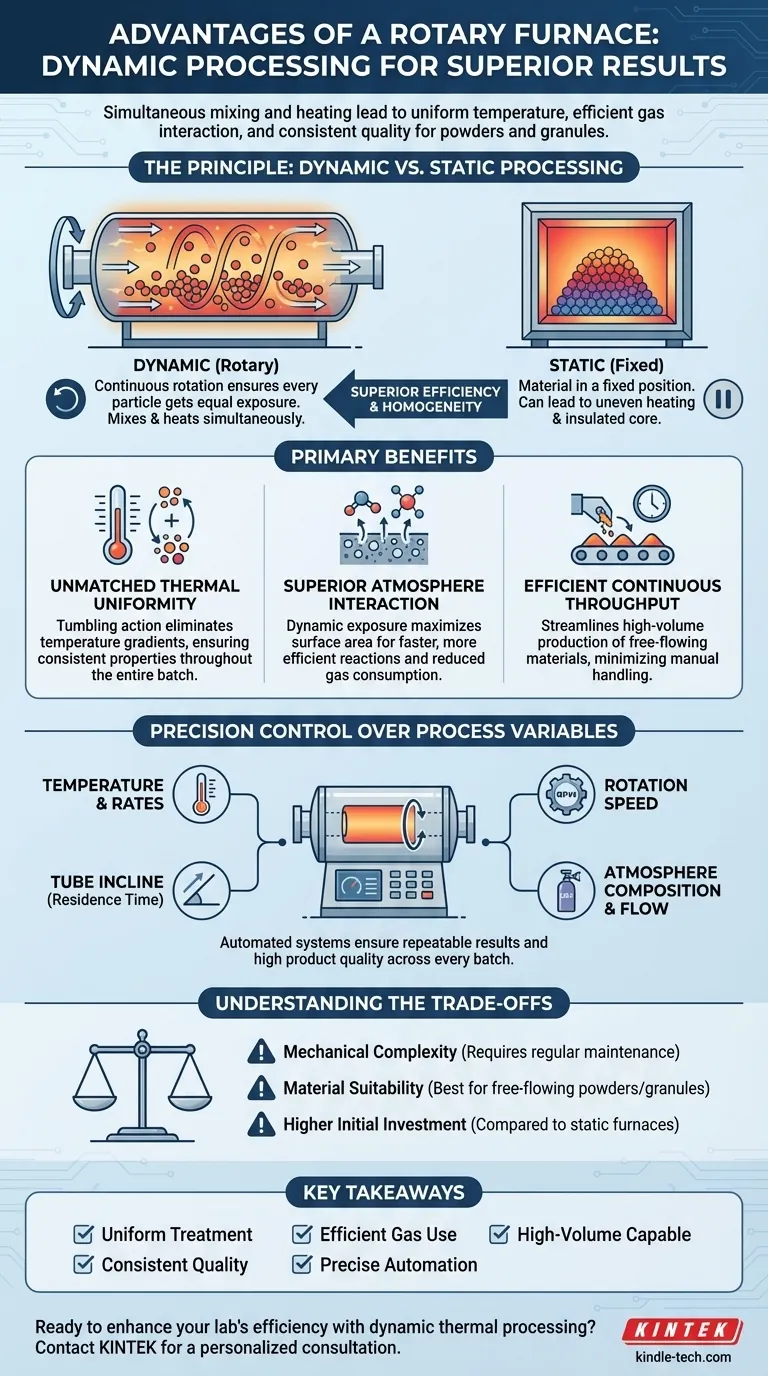

The Principle: Dynamic vs. Static Processing

The fundamental difference between a rotary tube furnace and a static furnace (like a box or standard tube furnace) is movement. This single principle of dynamic processing is the source of its most significant advantages.

Imagine cooking a single large item in an oven. If left in one spot, the side facing the heating element gets cooked faster than the side facing away. A rotary furnace is like a rotisserie; the constant rotation ensures every surface gets equal exposure to the heat source.

Unmatched Thermal Uniformity

In a static process, material at the bottom of a crucible can be insulated by the material above it, leading to temperature gradients and inconsistent treatment.

A rotary furnace eliminates this problem. The tumbling motion constantly brings cooler material from the core of the batch to the surface, and cycles hotter material from the surface back into the batch.

This constant mixing results in excellent temperature uniformity throughout the entire volume of material, which is critical for producing a homogenous final product with consistent properties.

Superior Atmosphere and Gas Interaction

Many thermal processes, such as sintering or chemical synthesis, require a specific gas atmosphere. The efficiency of these reactions depends on how well the gas interacts with the surface of the material.

The continuous movement of the sample constantly exposes new surface area to the process atmosphere. This dynamic exposure dramatically improves gas diffusion into the material.

The result is a more efficient reaction, faster processing times, and often a reduction in the total volume of process gas consumed compared to a static system. This is especially vital for high-temperature sintering in reducing atmospheres.

Efficient and Continuous Throughput

Rotary furnaces are exceptionally well-suited for continuous or high-volume batch processing. Material can be fed into one end of the tilted tube and slowly travel to the exit as it rotates, receiving the specified heat treatment along the way.

This design minimizes the need for manual material handling, especially for powders and granules, streamlining the production workflow and increasing overall throughput.

Precision Control Over Process Variables

Modern rotary furnaces are not just rotating tubes; they are highly engineered systems that offer precise control over every critical aspect of the thermal process.

Integrated Atmosphere Management

These furnaces are designed as sealed systems. They can be evacuated to create a vacuum or filled with a specific, controlled atmosphere.

This makes them ideal for processing oxygen-sensitive materials or for driving chemical reactions that require a particular environment, such as sintering metal powders or preparing certain battery materials.

Advanced Automation and Repeatability

The process is governed by an intelligent control system. Operators can precisely manage key parameters, including:

- Temperature and heating/cooling rates

- Rotation speed

- Tube incline angle (which controls residence time)

- Atmosphere composition and flow rate

This level of automation ensures that every batch is processed under identical conditions, guaranteeing repeatable results and high product quality.

Understanding the Trade-offs

No technology is a universal solution. The advantages of a rotary furnace come with specific considerations that make it ideal for some applications but less so for others.

Mechanical Complexity and Maintenance

The rotation mechanism, including the drive motor and rotary seals, introduces moving parts that are not present in a static furnace. These components require regular inspection and maintenance to ensure a reliable, gas-tight seal and smooth operation.

Material Suitability

A rotary furnace works best with free-flowing powders, granules, or small parts that can tumble freely. Materials that are sticky, prone to agglomeration, or could be damaged by the tumbling action may not be suitable for this type of processing.

Initial Investment

Due to their mechanical complexity and advanced control systems, rotary furnaces typically represent a higher initial capital investment compared to a simple box or static tube furnace of similar size.

Making the Right Choice for Your Application

Selecting the right furnace requires aligning its capabilities with your primary process goal.

- If your primary focus is high-volume powder processing: The continuous throughput and excellent thermal uniformity make the rotary furnace an ideal choice for ensuring consistent quality across large batches.

- If your primary focus is efficient chemical reactions or coating: The superior gas interaction from the tumbling motion will maximize reaction efficiency and reduce processing time and gas consumption.

- If your primary focus is producing high-purity materials in a controlled atmosphere: The sealed system and precise atmospheric control are critical for processes like sintering advanced ceramics or producing low-impurity metallurgical products.

Ultimately, choosing a rotary furnace is a decision to prioritize dynamic processing for the sake of uniformity, efficiency, and control.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Dynamic Processing | Simultaneous mixing and heating for uniform treatment |

| Thermal Uniformity | Eliminates temperature gradients for consistent product quality |

| Efficient Gas Interaction | Maximizes surface area exposure, reducing gas consumption |

| Continuous Throughput | Ideal for high-volume powder and granule processing |

| Precise Process Control | Automated control over temperature, rotation, and atmosphere |

Ready to enhance your lab's efficiency with dynamic thermal processing?

A rotary furnace from KINTEK delivers the precise mixing, heating, and atmospheric control required for consistent, high-quality results with powders, granules, and other free-flowing materials. Our expertise in lab equipment ensures you get a solution tailored to your specific application, whether it's sintering, chemical synthesis, or high-volume production.

Let's discuss how a KINTEK rotary furnace can optimize your process. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the optimum temperature for pyrolysis? Target Your Desired Biochar, Bio-oil, or Syngas

- What is different between calcination? Unlocking Thermal Processing for Material Science

- How does time affect pyrolysis? Master Residence Time to Control Biochar, Bio-Oil, and Syngas Yields

- What is the difference between calcining and roasting? A Guide to High-Temperature Processing

- What is the function of a pyrolysis reactor? Transform Waste into Valuable Resources with Thermal Cracking

- How is combustion similar to pyrolysis? Unlocking the Thermal Decomposition Pathways

- What are the advantages and disadvantages of rotary furnace? Maximize Uniformity & Efficiency in Thermal Processing

- What are the products of the pyrolysis of plastic? Unlock Fuel, Gas, and Char from Waste