The single greatest advantage of the Chemical Vapor Deposition (CVD) method for producing Carbon Nanotubes (CNTs) is its unparalleled level of control. By precisely adjusting deposition parameters, CVD allows for the synthesis of high-purity CNTs with specific, predetermined structures, making it the dominant method for both industrial-scale production and advanced research.

While other methods can produce CNTs, CVD is the preferred industrial process because it uniquely transforms nanotube synthesis from a brute-force discovery process into a tunable engineering discipline. It offers the control necessary to build for specific applications.

Why CVD Dominates CNT Synthesis

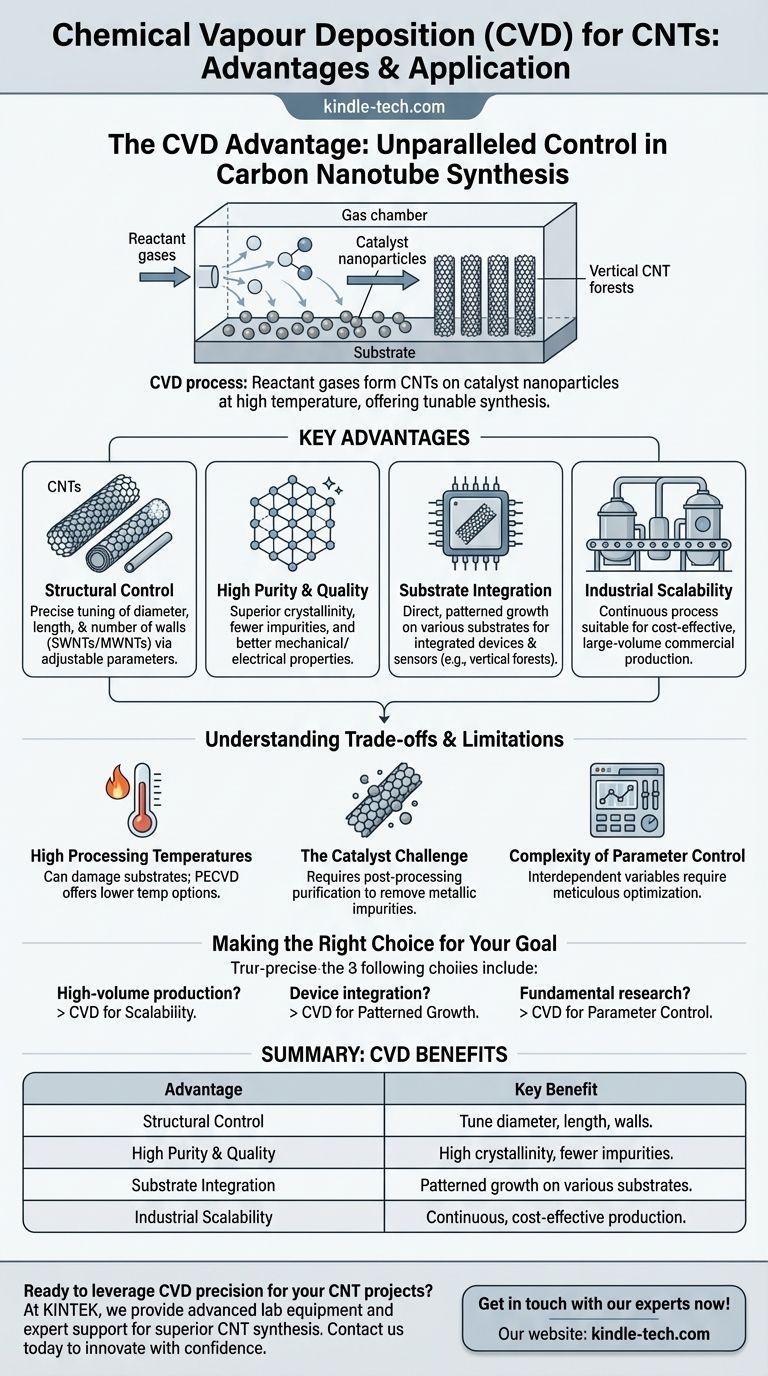

The CVD process works by introducing reactant gases into a chamber containing a substrate coated with catalyst nanoparticles. At high temperatures, a chemical reaction breaks down the gas, and carbon atoms assemble on the catalyst particles, growing into nanotubes. The advantages of this method stem directly from the fine control it offers over every stage of this process.

Unmatched Control Over Nanotube Structure

The properties of a CNT are dictated by its structure—its diameter, length, and number of walls. CVD allows for direct influence over these characteristics.

By adjusting variables like temperature, pressure, gas composition, and flow rate, you can tune the final product. This makes it possible to selectively grow single-walled or multi-walled CNTs and control their diameter and length, a level of precision other methods cannot easily match.

High Purity and Crystalline Quality

The CVD process results in CNTs with high purity and good crystallization. This is critical because defects in the nanotube's carbon lattice can severely degrade its exceptional mechanical strength and electrical conductivity.

Because the reactants are supplied externally as clean gases, the resulting nanotubes have very few amorphous carbon impurities compared to methods like arc discharge. The controlled, stable growth environment also promotes the formation of a well-ordered structure with low residual stress.

Versatility in Growth and Substrate Integration

A key advantage of CVD is its ability to grow CNTs directly onto a wide variety of substrates. This is essential for creating integrated devices, such as sensors, transistors, and interconnects in microelectronics.

The method allows for patterned growth, meaning you can pre-define where the catalyst is placed on a substrate to grow CNTs in specific locations and orientations. This includes growing vertically aligned "forests" of CNTs, which is impossible with other techniques.

Scalability for Industrial Production

Unlike batch-based processes like laser ablation, CVD is a continuous or semi-continuous process that is highly scalable. The ability to use larger reactors and maintain a constant flow of reactant gases makes it the most economically viable method for producing large quantities of CNTs for commercial applications.

Understanding the Trade-offs and Limitations

No method is perfect. To leverage CVD effectively, you must understand its inherent challenges.

High Processing Temperatures

Traditional thermal CVD operates at very high temperatures, typically between 850°C and 1100°C. These temperatures can damage or destroy many useful substrate materials, such as polymers or certain types of processed silicon wafers.

However, techniques like Plasma-Enhanced CVD (PECVD) can significantly lower the required temperature, expanding the range of compatible substrates, though this adds complexity to the system.

The Catalyst Challenge

CVD relies on metal catalyst nanoparticles (like iron, nickel, or cobalt) to nucleate nanotube growth. After synthesis, these metallic impurities often remain embedded in the CNTs.

Removing these catalyst particles requires aggressive post-processing purification steps, often involving strong acids. This purification process can be costly, time-consuming, and can introduce defects into the nanotubes, potentially compromising their quality.

Complexity of Parameter Control

The greatest strength of CVD—its high degree of control—is also a source of its complexity. The process involves numerous interdependent variables (temperature, pressure, gas mixture, flow rates, catalyst type and size).

Achieving a specific, repeatable outcome requires meticulous optimization and process control. A small deviation in one parameter can significantly alter the final product, demanding sophisticated monitoring and engineering to maintain consistency.

Making the Right Choice for Your Goal

Your application dictates whether CVD is the right approach.

- If your primary focus is high-volume, cost-effective production: CVD offers the best scalability for producing large quantities of high-purity CNTs for bulk material applications.

- If your primary focus is integrating CNTs directly into devices: CVD's unique ability to grow nanotubes on specific substrates in predefined patterns is its defining advantage for electronics and sensors.

- If your primary focus is fundamental research with specific properties: CVD provides the unparalleled parameter control needed to precisely tune CNT diameter, length, and alignment for targeted experiments.

Ultimately, understanding CVD's balance of precision, scalability, and complexity is the key to unlocking its full potential for carbon nanotube innovation.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Structural Control | Tune diameter, length, and number of walls (SWNTs/MWNTs) by adjusting parameters. |

| High Purity & Quality | Produces CNTs with high crystallinity and fewer impurities compared to other methods. |

| Substrate Integration | Enables direct, patterned growth on various substrates for device fabrication. |

| Industrial Scalability | Continuous process allows for cost-effective, large-volume production. |

Ready to leverage the precision of Chemical Vapor Deposition for your carbon nanotube projects?

At KINTEK, we specialize in providing the advanced lab equipment and expert support you need to master CNT synthesis. Whether you are scaling up for industrial production or conducting cutting-edge research, our solutions are designed to help you achieve superior control, purity, and yield.

Contact us today to discuss how we can support your specific laboratory needs and help you innovate with confidence.

Get in touch with our experts now!

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision

- What role does Chemical Vapor Deposition (CVD) equipment play in the preparation of C/C composites? Expert Analysis

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition

- What are the advantages of industrial CVD for solid boriding? Superior Process Control and Material Integrity