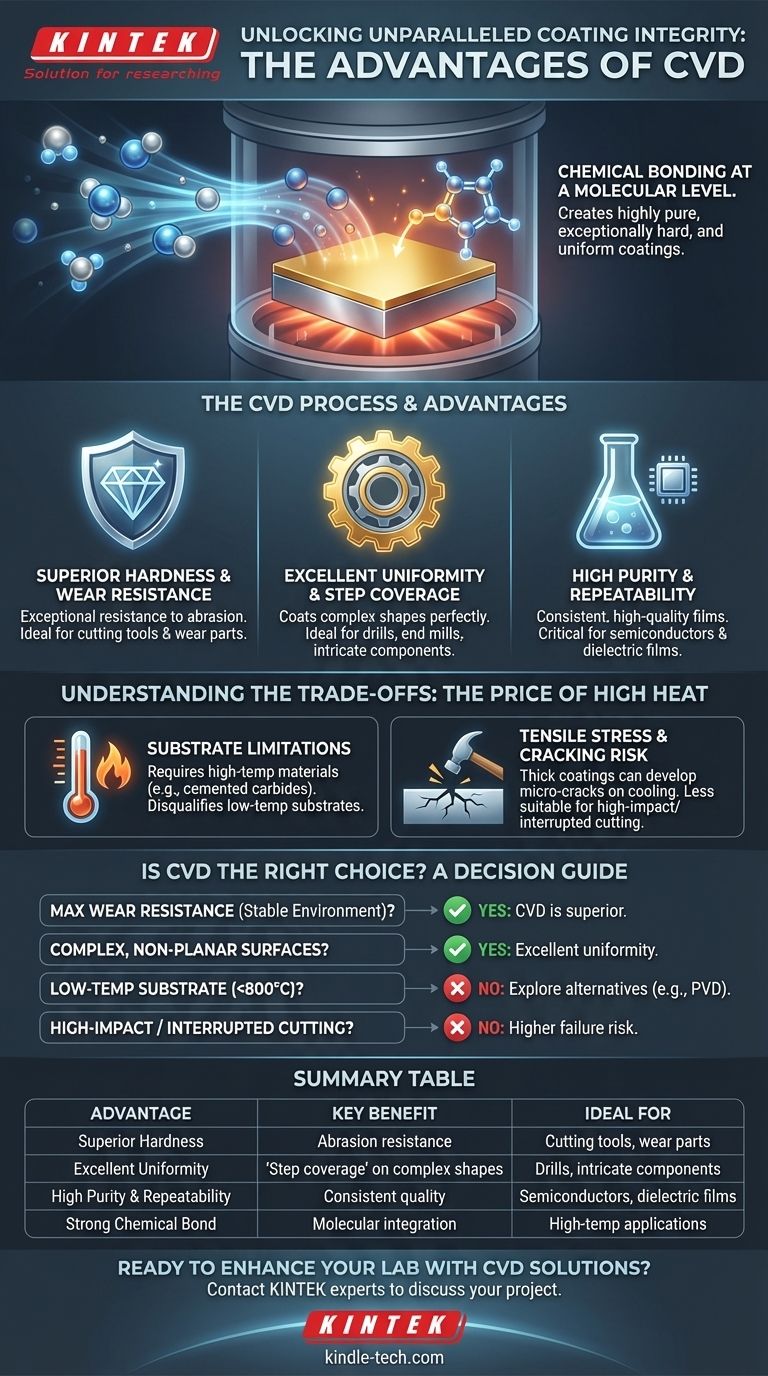

At its core, Chemical Vapor Deposition (CVD) offers unparalleled coating integrity. This process creates highly pure, exceptionally hard, and remarkably uniform coatings by chemically bonding new material directly to a substrate at a molecular level. The result is a film that is not merely layered on top, but fundamentally integrated with the surface it protects.

While CVD's high-temperature process creates exceptionally hard and well-bonded coatings ideal for wear resistance, this same requirement restricts its use to substrates that can withstand extreme heat and makes it less suitable for applications involving sharp, repeated impacts.

The Foundation of CVD: Chemical Bonding

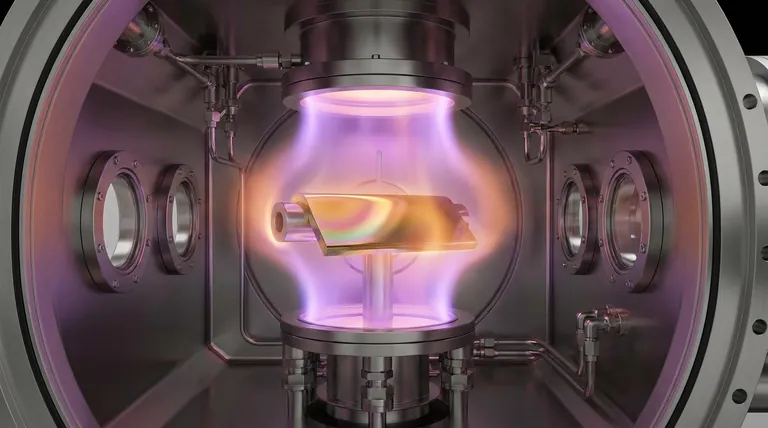

To understand the advantages of CVD, you must first understand its fundamental process. Unlike physical deposition methods that essentially "spray" a material onto a surface, CVD builds the coating through a chemical reaction.

How the Process Works

A volatile precursor gas containing the desired coating elements is introduced into a vacuum chamber with the substrate. The chamber is heated to an extremely high temperature, often between 800°C and 1000°C. This heat triggers a chemical reaction, breaking the gas down and causing the desired material to deposit and bond with the substrate's surface.

The Result: A Strong, Integrated Film

Because the coating is formed through a chemical bond rather than a mechanical one, the adhesion is exceptionally strong. The resulting film becomes a new, integral part of the substrate's surface, leading to superior durability and performance under specific conditions.

Key Advantages of CVD Coatings

The chemical nature of the CVD process gives rise to several distinct advantages, making it the preferred choice for certain demanding applications.

Superior Hardness and Wear Resistance

The strong, dense, and often crystalline structure of CVD coatings provides exceptional hardness and resistance to abrasion. This makes it a primary choice for protecting cutting tools and other components subjected to constant friction and wear.

Excellent Uniformity and "Step Coverage"

Because the deposition occurs from a gas phase, the coating molecules can reach every part of the substrate's surface. This allows CVD to apply a highly uniform film over complex and irregularly shaped objects, such as the flutes of a drill bit or the teeth of an end mill, a property known as excellent step coverage.

High Purity and Repeatability

The controlled vacuum environment and chemical precursors allow for the creation of extremely high-purity films. This precision and control also ensure excellent repeatability from one batch to the next, which is critical for high-tech applications like manufacturing semiconductor and dielectric films (e.g., SiO2, Si3N4).

Understanding the Trade-offs: The Price of High Temperature

The primary advantages of CVD are intrinsically linked to its greatest limitations. The high-temperature nature of the process introduces critical trade-offs that must be considered.

Substrate Material Limitations

The process temperature of 800-1000°C immediately disqualifies any substrate material that cannot withstand that heat without melting, warping, or losing its structural integrity. This generally restricts CVD to high-temperature materials like cemented carbides.

Risk of Tensile Stress and Cracking

CVD often produces a relatively thick coating (10-20μm). As the coated part cools from the extreme process temperature, the difference in thermal contraction between the substrate and the thick coating can generate significant tensile stress. This stress can lead to the formation of fine, microscopic cracks in the coating.

Unsuitability for Interrupted Cutting

While these micro-cracks may not be an issue in stable conditions, they represent a significant point of failure in applications with non-uniform force. In processes like milling, where the tool engages and disengages with the material (interrupted cutting), the repeated impacts can cause these cracks to propagate, leading to the coating chipping or peeling off entirely.

Is CVD the Right Choice for Your Application?

Choosing the right coating technology requires weighing its advantages against the specific demands of your use case. Use these points as a guide.

- If your primary focus is maximum wear resistance in a stable environment: CVD is likely the superior choice due to its exceptional hardness and bond strength.

- If your application involves coating complex, non-planar surfaces: CVD's gas-phase process provides excellent uniformity and step coverage that is difficult to match.

- If your substrate cannot withstand high temperatures (above 800°C): CVD is not a viable option, and you must explore lower-temperature alternatives like Physical Vapor Deposition (PVD).

- If your process involves high-impact forces or interrupted cutting: The inherent tensile stress in thick CVD coatings creates a higher risk for failure, making it less suitable than more ductile options.

Understanding these fundamental trade-offs is the key to selecting the right surface treatment for optimal performance and longevity.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Superior Hardness | Exceptional resistance to abrasion and wear | Cutting tools, wear parts |

| Excellent Uniformity | Uniform film over complex shapes (step coverage) | Drills, end mills, intricate components |

| High Purity & Repeatability | Consistent, high-quality coatings batch after batch | Semiconductors, dielectric films |

| Strong Chemical Bond | Coating integrates with substrate at molecular level | High-temperature applications |

Ready to enhance your lab's capabilities with CVD coating solutions?

KINTEK specializes in advanced lab equipment and consumables for precise surface treatment applications. Our expertise in CVD technology can help you achieve superior coating performance for your most demanding projects.

Contact our experts today to discuss how our CVD solutions can bring unmatched hardness, uniformity, and durability to your laboratory operations!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer

- What are the methods of carbon nanotube purification? Achieve High-Purity CNTs for Your Application

- What is chemical Vapour deposition method for CNT? Achieve Precise Control for High-Quality Nanotube Growth

- What is the temperature range of LPCVD? From 425°C to 900°C for Superior Thin Films

- What is the growth process of MOCVD? A Step-by-Step Guide to Epitaxial Thin Film Deposition

- What is the vacuum deposition of film? A Guide to Ultra-Thin, High-Purity Coatings

- What are the methods of chemical vapor deposition of graphene? A Guide to TCVD, PECVD, and More

- What temperature does physical vapor deposition occur? A Guide from Room Temp to 1000°C