The primary advantages of CVD diamonds are their high purity and quality, lower cost, and significantly smaller ethical and environmental footprint. Created in a laboratory through a process called Chemical Vapor Deposition (CVD), these gems are chemically, physically, and optically identical to mined diamonds but are produced in a more controlled and efficient manner.

Choosing a CVD diamond is not a compromise on quality, but rather a decision based on different priorities. The core advantage lies in gaining a chemically identical, high-quality diamond without the immense environmental and ethical costs associated with traditional mining.

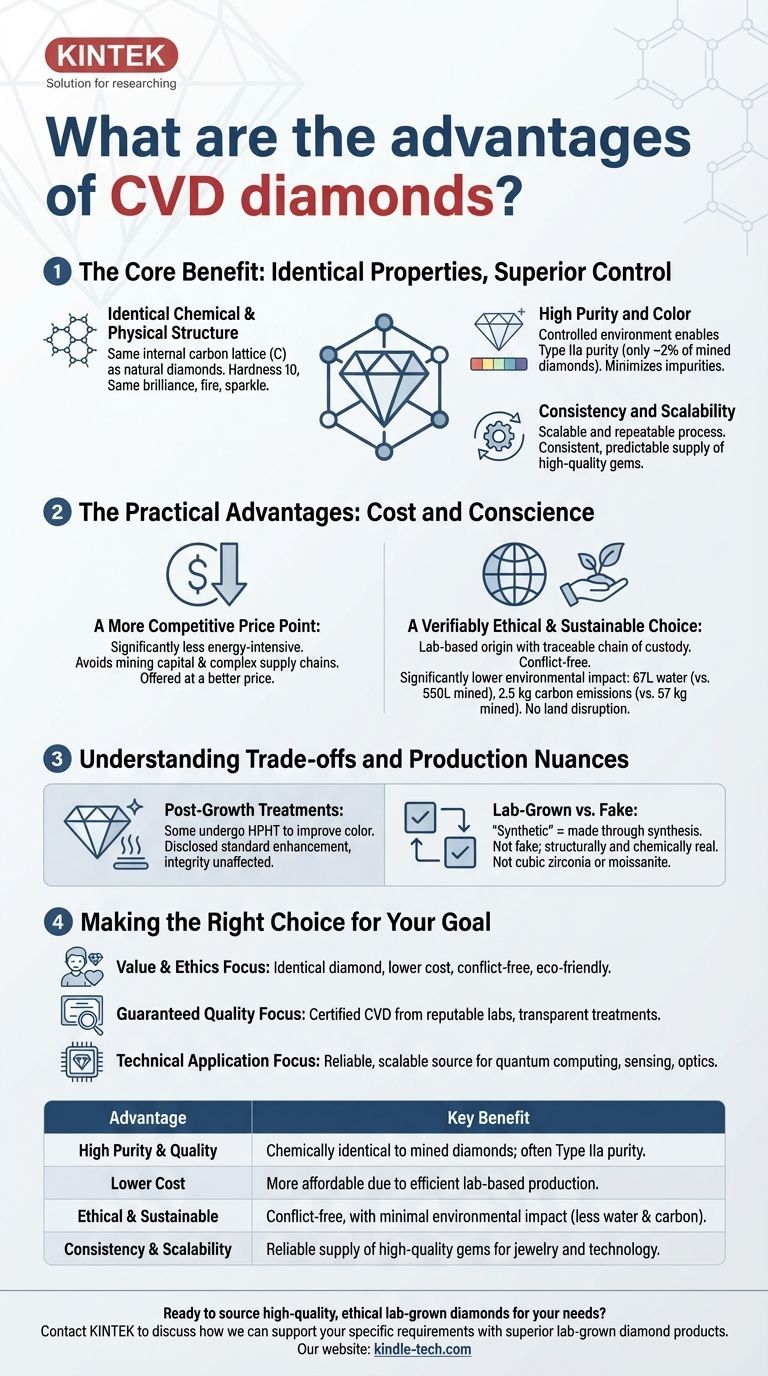

The Core Benefit: Identical Properties, Superior Control

The CVD process allows for a level of control and predictability that is impossible with geological formation. This results in a final product that is, by every scientific measure, a real diamond.

Identical Chemical and Physical Structure

CVD diamonds are not imitations. They share the exact same internal carbon lattice structure as natural diamonds.

This means they have the same physical properties, including a hardness of 10 on the Mohs scale, making them exceptionally durable for everyday wear. They also exhibit the same brilliance, fire, and sparkle.

High Purity and Color

The controlled environment of a CVD reactor allows for the creation of diamonds with very high clarity and color, often classified as Type IIa—a category that includes only about 2% of the world's mined diamonds.

This purity is a direct result of the process, which uses a hydrocarbon gas mixture to build the diamond atom by atom, minimizing the inclusion of impurities like nitrogen that can cause yellowing.

Consistency and Scalability

Unlike mining, which relies on discovering finite deposits, the CVD process is scalable and repeatable.

This manufacturing control leads to a consistent and predictable supply of high-quality diamonds, which is particularly crucial for industrial and technological applications that require uniform material properties.

The Practical Advantages: Cost and Conscience

The efficiency of the laboratory process translates directly into tangible benefits for the buyer and the planet.

A More Competitive Price Point

The CVD process is significantly less energy-intensive and does not require the massive capital investment and operational costs of large-scale mining.

By avoiding a long and complex supply chain, CVD diamonds can be offered at a more competitive price than mined diamonds of comparable size and quality.

A Verifiably Ethical Choice

CVD diamonds are, by their nature, socially responsible. Their lab-based origin provides a clear and traceable chain of custody, guaranteeing they are not "conflict diamonds."

This completely sidesteps the ethical and humanitarian concerns that have historically plagued the diamond mining industry.

Significantly Lower Environmental Impact

The environmental benefits are stark when compared to mining. Creating a one-carat lab-grown diamond is vastly more sustainable.

According to data, the process uses 67 liters of water versus 550 for a mined diamond and produces just 2.5 kg of carbon emissions compared to 57 kg for its mined equivalent. It also avoids the massive land disruption and mineral waste of mining operations.

Understanding the Trade-offs and Production Nuances

While the advantages are clear, it is crucial to understand the nuances of the production process to make a fully informed decision.

The Role of Post-Growth Treatments

Some CVD diamonds are produced with a brownish tint due to minor structural imperfections. These diamonds often undergo a post-growth treatment, like High-Pressure/High-Temperature (HPHT), to permanently improve their color.

This is a standard enhancement process, but reputable sellers will always disclose if a diamond has been treated. It does not affect the diamond's integrity but is an important factor in its history and valuation.

Distinguishing "Lab-Grown" from "Fake"

There is often confusion around terms like "synthetic." In a scientific context, "synthetic" simply means "made through synthesis" rather than occurring naturally.

CVD diamonds are synthetic in this sense, but they are not fake. They are structurally and chemically real diamonds. Terms like "lab-grown" or "man-made" more accurately describe their origin without causing confusion with simulants like cubic zirconia or moissanite.

Making the Right Choice for Your Goal

Ultimately, the decision to choose a CVD diamond depends on your specific priorities.

- If your primary focus is value and ethics: CVD offers a visually and structurally identical diamond at a significantly lower cost, with a guaranteed conflict-free and environmentally friendly origin.

- If your primary focus is guaranteed quality: Look for certified CVD diamonds from reputable gemological labs that are transparent about any post-growth treatments to ensure you get the high-purity gem you expect.

- If your primary focus is a technical application: CVD technology provides a reliable and scalable source of high-purity diamond material, ideal for advanced uses in quantum computing, sensing, and optics.

CVD technology empowers you to acquire a genuine diamond whose quality and origin are defined by science, not by chance.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| High Purity & Quality | Chemically identical to mined diamonds; often Type IIa purity. |

| Lower Cost | More affordable due to efficient lab-based production. |

| Ethical & Sustainable | Conflict-free, with minimal environmental impact (less water & carbon). |

| Consistency & Scalability | Reliable supply of high-quality gems for jewelry and technology. |

Ready to source high-quality, ethical lab-grown diamonds for your needs?

Whether you're a jeweler seeking consistent, high-purity gems or a technology company requiring precision diamond material, KINTEK can provide the solution. Our expertise in lab equipment and consumables ensures you get the reliable, high-performance materials your projects demand.

Contact us today via our form to discuss how we can support your specific requirements with superior lab-grown diamond products.

Visual Guide

Related Products

- CVD Diamond for Thermal Management Applications

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Dressing Tools for Precision Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- Are CVD diamonds fake? Discover the Truth About Lab-Grown Diamonds

- What is the future value of lab grown diamond? Understanding Its Depreciating Financial Worth

- What is the main difference between CVD and natural diamond? Origin, Purity, and Value Explained

- Are CVD diamonds better than HPHT? The Real Truth About Lab-Grown Diamond Quality

- What is the process of lab created diamonds? A Clear Guide to HPHT & CVD Methods