At its core, a diamond cutting tool offers a combination of extreme hardness, exceptional wear resistance, and high thermal conductivity that is unmatched by other materials. These properties translate directly into higher machining precision, longer tool life, and greater overall production efficiency, particularly when working with non-ferrous and abrasive materials.

A diamond tool's primary advantage is not just its hardness, but its ability to manage heat and friction at the cutting edge. This unique combination allows for superior surface finishes and dimensional accuracy while dramatically extending the tool's operational life in the right applications.

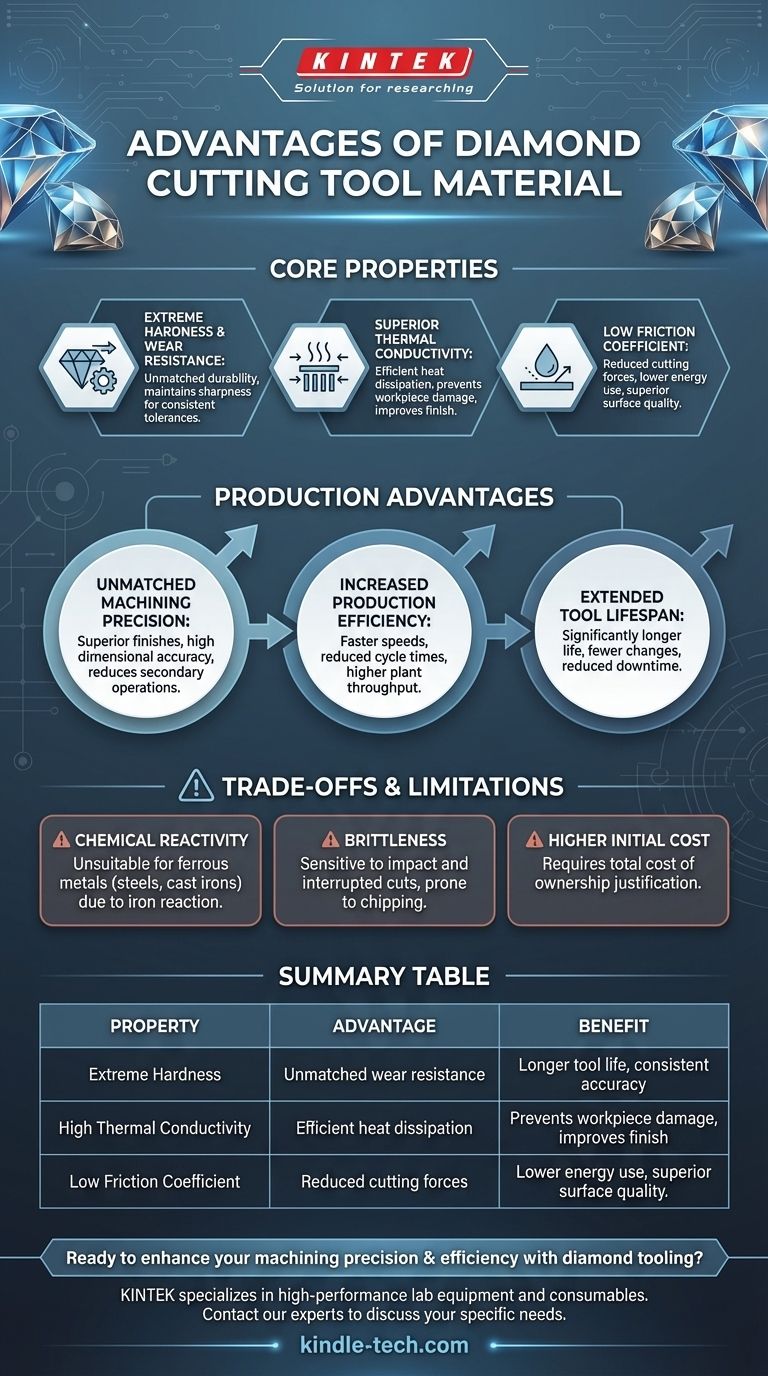

The Core Properties of Diamond Tools

The advantages of diamond tooling are a direct result of its fundamental physical characteristics. Understanding these properties explains why it performs so well in specific machining environments.

Extreme Hardness and Wear Resistance

As the hardest known material, diamond offers unparalleled resistance to abrasive wear. This means the cutting edge retains its sharpness for significantly longer than conventional tools.

This durability directly results in maintaining tight dimensional tolerances and consistent surface finishes over long production runs.

Superior Thermal Conductivity

Diamond is an exceptional thermal conductor, four to five times more so than copper. In machining, this allows it to pull heat away from the cutting zone and the workpiece very efficiently.

This rapid heat dissipation prevents thermal damage to the workpiece, such as burns or micro-cracks, which is critical for achieving high-quality surface integrity. It also reduces the thermal expansion of both the tool and the part, improving accuracy.

Low Friction Coefficient

Diamond has a very low coefficient of friction when machining most materials. This inherent "slipperiness" reduces the cutting forces required.

Lower forces mean less heat is generated in the first place, further contributing to better surface quality. It also reduces the load on the machine spindle and can lead to lower energy consumption.

Translating Properties into Production Advantages

These physical properties create tangible benefits on the shop floor, impacting everything from part quality to operational costs.

Unmatched Machining Precision

The combination of edge retention, thermal stability, and low cutting forces allows diamond tools to produce superior surface finishes and exceptional dimensional accuracy. This often reduces or eliminates the need for secondary finishing operations like grinding or polishing.

Increased Production Efficiency

Because diamond tools can withstand higher cutting speeds and feeds, cycle times can be significantly reduced. This ability to machine faster directly increases throughput and overall plant productivity.

Extended Tool Lifespan

The high wear resistance of diamond results in a tool life that can be many times longer than that of carbide or ceramic tools. This leads to fewer tool changes, significantly reducing machine downtime and operator intervention.

Understanding the Trade-offs and Limitations

While powerful, diamond is not a universal solution. An objective assessment requires acknowledging its specific limitations.

Chemical Reactivity with Ferrous Metals

This is the single most important limitation. At the high temperatures generated during machining, carbon from the diamond tool reacts with iron. This chemical affinity causes rapid tool degradation, making diamond unsuitable for machining steels, cast irons, and other ferrous alloys.

Brittleness and Impact Sensitivity

Diamond is extremely hard but also brittle. It does not tolerate shock or vibration well and is susceptible to chipping in applications with heavy impact loads or interrupted cuts.

Higher Initial Cost

Diamond tooling represents a significant upfront investment compared to other materials. The cost must be justified by calculating the total cost of ownership, including gains from longer life, reduced downtime, and higher productivity.

Types of Diamond Tooling

It is also important to recognize that "diamond" is a category, not a single material. The most common form in machining is Polycrystalline Diamond (PCD), which consists of synthetic diamond particles sintered together with a metallic binder. This structure provides greater toughness and impact resistance than a single-crystal diamond.

Making the Right Choice for Your Application

Selecting the correct tool material is about matching its properties to the workpiece material and the production goal.

- If your primary focus is high-volume machining of non-ferrous materials (e.g., aluminum, brass, copper, composites): Diamond is almost certainly the optimal choice for achieving the lowest cost-per-part through speed and tool life.

- If your primary focus is machining steel, stainless steel, or cast iron: You must avoid diamond and instead consider materials like Cubic Boron Nitride (CBN) or coated carbides.

- If your primary focus is achieving the absolute highest surface finish on a compatible material: Diamond tooling can often eliminate post-processing steps, justifying its cost through process simplification.

Ultimately, choosing a diamond tool is an economic and engineering decision driven by its unparalleled performance within its specific operational window.

Summary Table:

| Property | Advantage | Benefit |

|---|---|---|

| Extreme Hardness | Unmatched wear resistance | Longer tool life, consistent accuracy |

| High Thermal Conductivity | Efficient heat dissipation | Prevents workpiece damage, improves finish |

| Low Friction Coefficient | Reduced cutting forces | Lower energy use, superior surface quality |

Ready to enhance your machining precision and efficiency with diamond tooling?

KINTEK specializes in high-performance lab equipment and consumables, including cutting tools for demanding applications. Our expertise can help you select the right tooling to maximize productivity, reduce costs, and achieve unparalleled surface finishes on non-ferrous materials.

Contact our experts today to discuss how our solutions can benefit your specific laboratory or production needs.

Visual Guide

Related Products

- Professional Cutting Tools for Carbon Paper Cloth Diaphragm Copper Aluminum Foil and More

- CVD Diamond Cutting Tool Blanks for Precision Machining

- CVD Diamond for Thermal Management Applications

- Precision Wire Saw Laboratory Cutting Machine with 800mm x 800mm Workbench for Diamond Single Wire Circular Small Cutting

- Laboratory CVD Boron Doped Diamond Materials

People Also Ask

- What are the disadvantages of screw extrusion? High Costs and Complexity Explained

- What precautions should be taken when cutting carbon cloth? Avoid Short Circuits and Ensure Device Safety

- What are diamond coated tools used for? Conquer Abrasive Materials with Superior Tool Life

- What industrial uses are there for diamonds? Unlock High-Performance Applications

- What are the correct storage conditions for an RVC sheet? Ensure Long-Term Performance and Integrity