The primary advantage of Graphite Furnace Atomic Absorption Spectroscopy (GFAAS) is its exceptional sensitivity, allowing for the detection of elements at much lower concentrations—often parts per billion (ppb) or less—than other AAS techniques. This is achieved by atomizing the entire sample in a contained, controlled environment, which maximizes the signal and minimizes matrix interferences through precise temperature control.

The decision to use GFAAS is almost always driven by a single, critical need: to measure extremely low concentrations of an element with high precision, far beyond the capabilities of methods like Flame AAS.

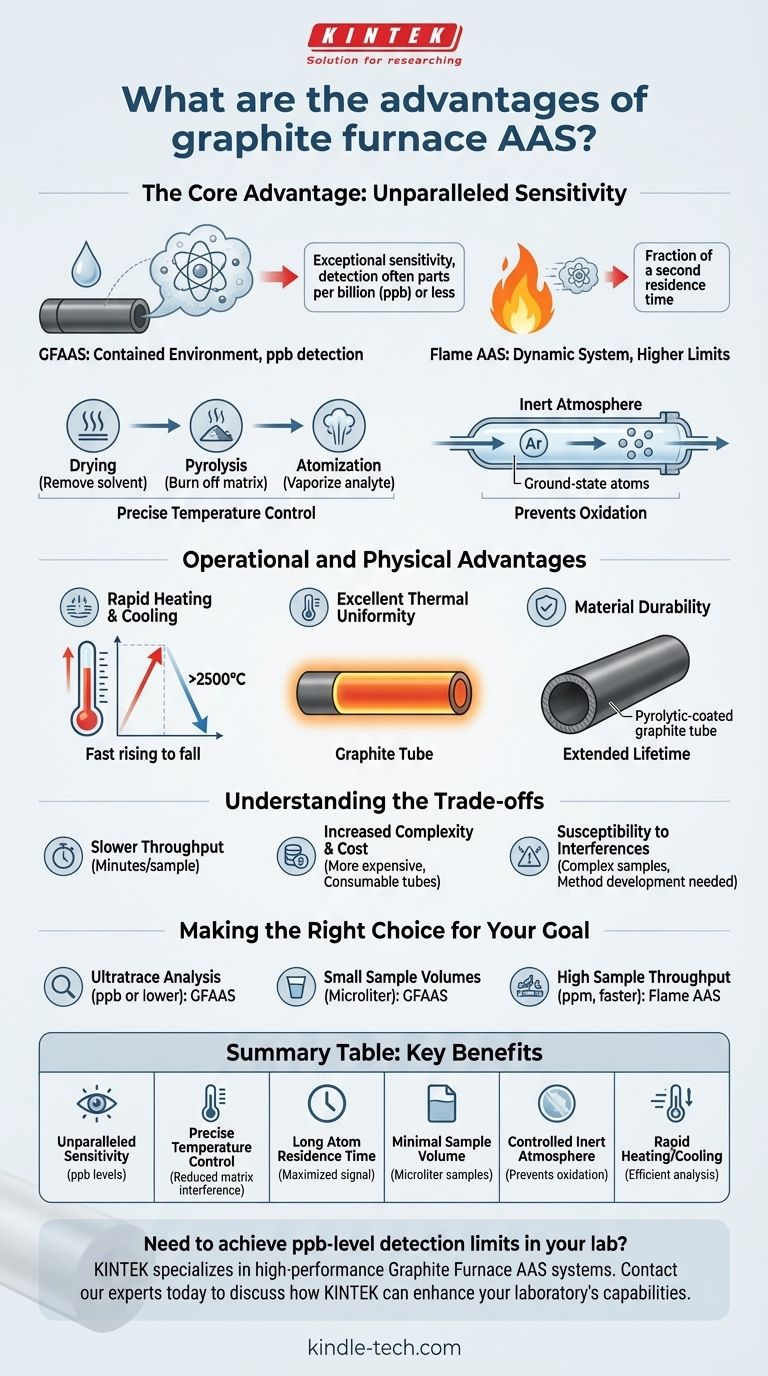

The Core Advantage: Unparalleled Sensitivity

The fundamental design of the graphite furnace is what gives the technique its power. Unlike a flame, which is a dynamic and open system, the graphite tube acts as a miniature furnace that gives the analyst precise control over the entire analytical process.

Why It's So Sensitive: Atom Residence Time

In GFAAS, a small, discrete sample (typically in the microliter range) is placed inside the graphite tube. The entire tube is then heated, holding the resulting cloud of atoms in the spectrophotometer's light path for several seconds.

This long residence time is the key. In contrast, atoms in Flame AAS pass through the light path in a fraction of a second, resulting in a much weaker signal for the same concentration.

The Power of Precise Temperature Control

GFAAS employs a multi-step temperature program that methodically prepares the sample before the final measurement. This process is crucial for reducing interference.

The typical program includes a drying step to remove the solvent, a pyrolysis (or ashing) step to burn off organic matrix components, and finally, a rapid atomization step to vaporize the target analyte for measurement. This programmatic removal of the matrix drastically reduces background noise.

A Controlled Inert Atmosphere

The graphite tube is continuously purged with an inert gas, typically argon. This serves a critical function: it prevents the hot analyte atoms from reacting with oxygen in the air.

By preventing oxidation, the system ensures a maximum population of ground-state atoms, which are the only atoms capable of absorbing light and generating a signal in AAS.

Operational and Physical Advantages

The choice of graphite as a material is not arbitrary. Its unique physical properties contribute directly to the performance of the instrument.

Rapid Heating and Cooling

Graphite has a low thermal capacity, meaning it can be heated to very high temperatures (over 2500°C) and cooled down again very quickly. This allows for rapid, well-defined temperature steps in the analysis program and shortens the overall time per sample.

Excellent Thermal Uniformity

As a near-perfect black body radiator, a heated graphite tube provides an extremely uniform temperature environment. This ensures that the entire sample is atomized consistently, leading to high precision and excellent reproducibility between measurements.

Material Durability

Modern graphite tubes are coated with a layer of pyrolytic graphite, which makes them less porous and more resistant to chemical attack. This extends the usable lifetime of the tube, a critical consumable component, and improves analytical performance.

Understanding the Trade-offs

While powerful, GFAAS is not the solution for every analytical problem. Its advantages in sensitivity come with practical limitations.

Slower Sample Throughput

GFAAS is inherently a sequential technique. Each sample must go through the entire temperature program, which can take several minutes. This results in a much lower throughput compared to Flame AAS, which can analyze samples every few seconds.

Increased Complexity and Cost

The instrumentation is more complex and expensive than a flame system. Furthermore, the graphite tubes are consumable items with a finite lifetime (typically a few hundred firings), adding to the ongoing operational cost of the analysis.

Susceptibility to Interferences

Despite the temperature program, GFAAS can be prone to severe matrix interferences. Complex samples can require extensive method development and the use of chemical modifiers or advanced background correction techniques to achieve accurate results.

Making the Right Choice for Your Goal

Selecting the correct atomic absorption technique depends entirely on your analytical requirements for sensitivity, sample volume, and throughput.

- If your primary focus is ultratrace analysis (ppb or lower): GFAAS is the definitive choice due to its superior atomization efficiency and low detection limits.

- If you are working with very small or precious sample volumes: The ability of GFAAS to analyze microliter-sized samples makes it the only viable option.

- If your primary focus is high sample throughput for concentrations in the ppm range: Flame AAS is a more practical, faster, and cost-effective solution.

Ultimately, understanding the fundamental strengths of GFAAS allows you to apply its exceptional sensitivity to the most demanding analytical challenges.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Unparalleled Sensitivity | Detects elements at parts per billion (ppb) levels or lower |

| Precise Temperature Control | Multi-step program (drying, pyrolysis, atomization) reduces matrix interference |

| Long Atom Residence Time | Atoms remain in light path for seconds, maximizing signal |

| Minimal Sample Volume | Analyzes microliter-sized samples, ideal for precious materials |

| Controlled Inert Atmosphere | Argon purge prevents oxidation, ensuring accurate measurements |

| Rapid Heating/Cooling | Graphite tube enables fast temperature cycles for efficient analysis |

Need to achieve ppb-level detection limits in your lab?

KINTEK specializes in providing high-performance lab equipment, including Graphite Furnace AAS systems, to help you meet the most demanding analytical challenges. Our expertise ensures you get the sensitivity and precision required for ultratrace analysis.

Contact our experts today to discuss how a GFAAS solution from KINTEK can enhance your laboratory's capabilities and deliver reliable results for your trace element analysis needs.

Visual Guide

Related Products

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Graphite Vacuum Continuous Graphitization Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Large Vertical Graphite Vacuum Graphitization Furnace

People Also Ask

- Why is graphite furnace more sensitive than flame? Unlocking Ultra-Trace Detection for Your Lab

- What are the stages of graphite furnace? A Guide to Precise Multi-Stage Temperature Programming

- What are the benefits of a graphite furnace? Achieve Rapid, Uniform High-Temperature Processing

- What does graphite furnace measure? A Key Tool for Trace Analysis & High-Temp Processing

- What is the principle of graphite furnace? Achieve Extreme Temperatures with Direct Resistive Heating

- Is graphite good for high temperature? Unlock Its Full Potential in Controlled Atmospheres

- What does a graphite furnace do? Achieve Extreme Heat and Ultra-Sensitive Analysis

- What is the purpose of a graphite furnace? Achieve Extreme Temperatures for Advanced Materials