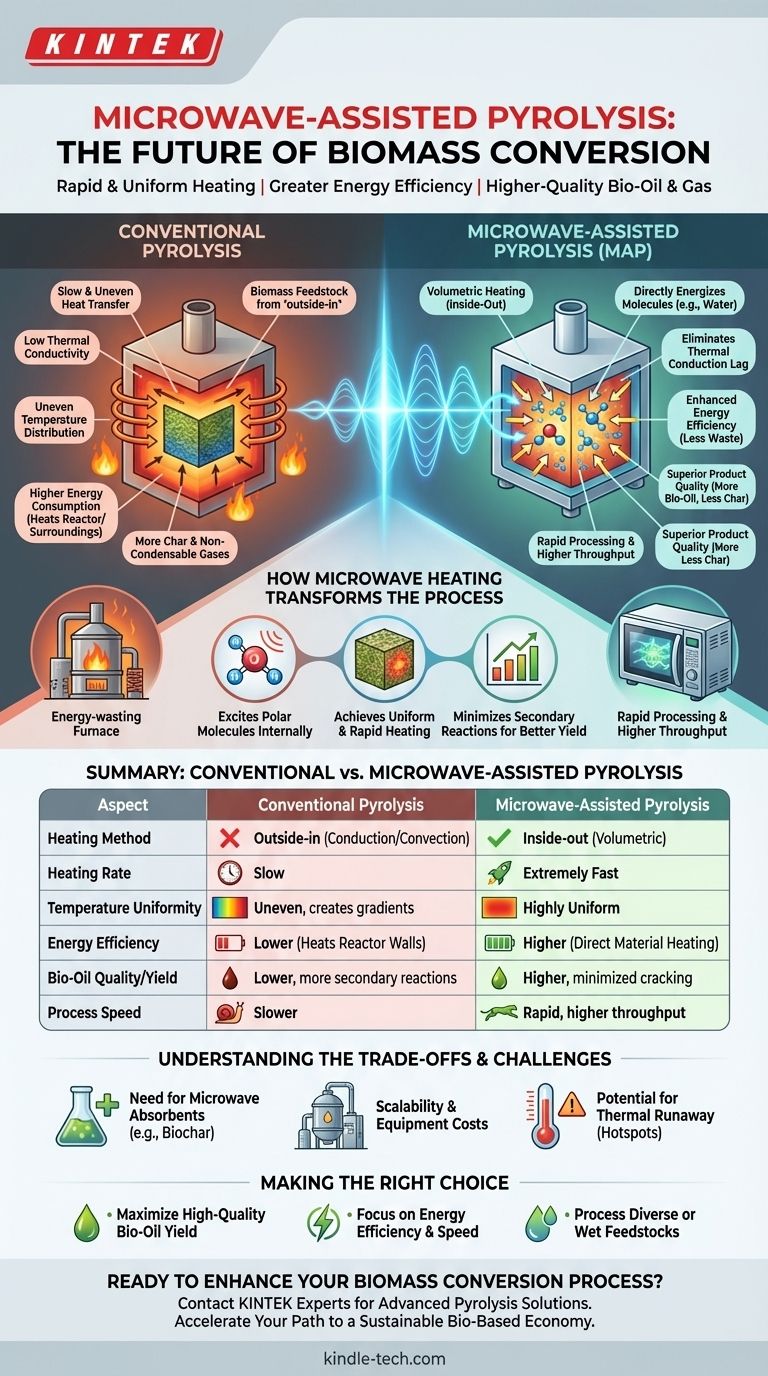

The primary advantages of microwave-assisted pyrolysis are its rapid and uniform heating, greater energy efficiency, and ability to produce higher-quality bio-oil and gas. This technology fundamentally changes how thermal energy is delivered to the feedstock, heating the material from the inside out, which provides significantly more control over the conversion process compared to conventional methods.

At its core, microwave-assisted pyrolysis overcomes the slow and inefficient heat transfer of traditional furnaces. By directly energizing the molecules within the feedstock, it offers a faster, more precise, and often more economical path to converting biomass into valuable energy products.

The Limitation of Conventional Pyrolysis

Conventional pyrolysis relies on thermal conduction, convection, and radiation to heat biomass from an external source. This "outside-in" approach is fundamentally slow and inefficient.

Slow and Uneven Heat Transfer

The low thermal conductivity of most biomass feedstocks means heat struggles to penetrate the material. This results in an uneven temperature distribution, where the outside is much hotter than the core.

This temperature gradient can lead to secondary reactions and the over-production of less valuable byproducts like char and non-condensable gases.

Higher Energy Consumption

In traditional systems, the entire reactor vessel and its surroundings must be heated to the target temperature. A significant amount of energy is lost to the environment, increasing both operational costs and the process's overall carbon footprint.

How Microwave Heating Transforms the Process

Microwave-assisted pyrolysis (MAP) is not just a faster way of heating; it is a different physical mechanism altogether. It leverages the dielectric properties of the material for a more targeted and efficient energy transfer.

Volumetric Heating: A Fundamental Shift

Microwaves pass through the material and directly excite polar molecules (like water) within the feedstock. This generates heat internally and simultaneously throughout the material's volume.

This "inside-out" volumetric heating eliminates the slow process of thermal conduction, leading to a much more uniform temperature profile.

Enhanced Energy Efficiency

Because the energy is delivered directly to the material being processed, less energy is wasted heating the reactor walls and surrounding air. The system can be brought to the target temperature much faster, reducing overall energy consumption.

Superior Product Quality and Yield

The precise and uniform heating minimizes unwanted secondary cracking of vapors. This typically results in a higher yield of high-quality pyrolysis oil (bio-oil) and a lower yield of residual biochar.

Rapid Processing and Greater Throughput

The incredibly fast heating rates—often orders of magnitude higher than conventional methods—dramatically shorten the time required for the pyrolysis process. This allows for smaller reactor footprints and increased operational throughput.

Understanding the Trade-offs and Challenges

While powerful, microwave-assisted pyrolysis is not without its specific considerations. Objectivity requires understanding its limitations.

The Need for Microwave Absorbents

Many dry biomass materials have poor dielectric properties, meaning they don't absorb microwave energy well on their own.

To overcome this, a highly microwave-absorbent material, such as biochar or silicon carbide, is often mixed with the feedstock to initiate and sustain the heating process.

Scalability and Equipment Costs

Designing large-scale, industrial microwave reactors presents engineering challenges, particularly in ensuring an even distribution of the microwave field. The initial capital cost for specialized microwave equipment can also be higher than for traditional furnaces.

Potential for Thermal Runaway

The rapid heating rates, if not properly controlled, can lead to localized "hotspots." This can cause thermal runaway, potentially damaging the equipment and negatively affecting the consistency of the final products.

Making the Right Choice for Your Goal

Selecting the right pyrolysis technology depends entirely on your primary objective.

- If your primary focus is maximizing high-quality bio-oil yield: Microwave-assisted pyrolysis is a superior choice due to its precise temperature control and ability to minimize unwanted secondary reactions.

- If your primary focus is energy efficiency and speed: The direct, volumetric heating of microwaves offers significantly lower energy consumption and faster processing times, increasing throughput.

- If your primary focus is processing diverse or wet feedstocks: Microwaves are particularly effective at heating materials containing water, potentially simplifying the pre-drying stage required in conventional systems.

Ultimately, embracing microwave technology allows for a more controlled and efficient method of converting biomass into the valuable components of a sustainable, bio-based economy.

Summary Table:

| Aspect | Conventional Pyrolysis | Microwave-Assisted Pyrolysis |

|---|---|---|

| Heating Method | Outside-in (conduction/convection) | Inside-out (volumetric) |

| Heating Rate | Slow | Extremely Fast |

| Temperature Uniformity | Uneven, creates gradients | Highly Uniform |

| Energy Efficiency | Lower (heats reactor walls) | Higher (direct material heating) |

| Bio-Oil Quality/Yield | Lower, more secondary reactions | Higher, minimized cracking |

| Process Speed | Slower | Rapid, higher throughput |

Ready to Enhance Your Biomass Conversion Process?

If your goal is to maximize high-quality bio-oil yield, improve energy efficiency, or increase processing throughput, KINTEK's expertise in advanced pyrolysis technology can help. We specialize in providing robust lab equipment and consumables tailored to your research and development needs in sustainable energy.

Contact our experts today to discuss how our solutions can accelerate your path to a more efficient and sustainable bio-based economy.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Performance Laboratory Freeze Dryer

- High Performance Laboratory Freeze Dryer for Research and Development

People Also Ask

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas