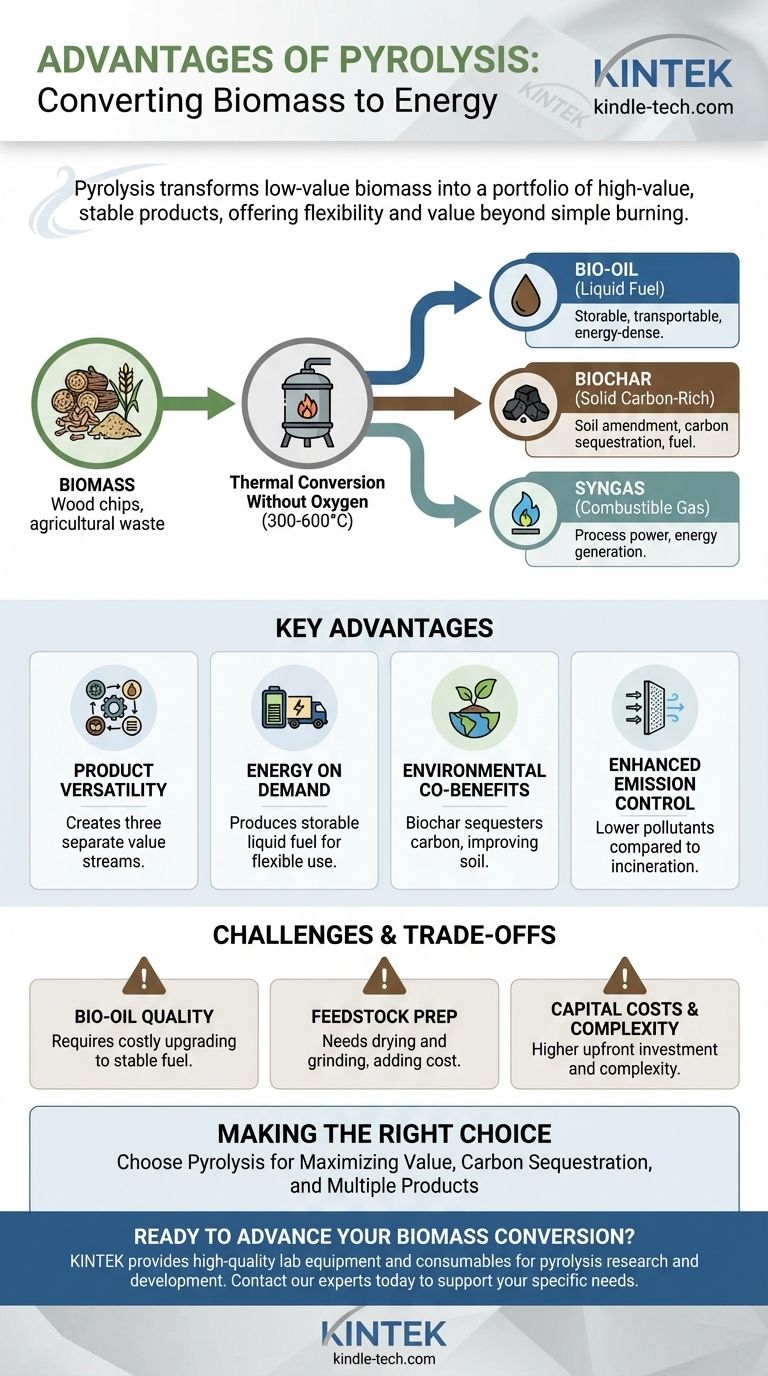

The primary advantage of pyrolysis is its unique ability to convert biomass into three distinct and valuable products—a liquid fuel (bio-oil), a solid carbon-rich material (biochar), and a combustible gas (syngas). Unlike direct combustion which simply releases heat, pyrolysis refines biomass into storable and transportable energy carriers and materials, offering significantly greater flexibility and value.

The true power of pyrolysis lies not just in generating energy, but in transforming low-value, bulky biomass into a portfolio of higher-value, stable products. This conversion creates new revenue streams and environmental benefits that simple burning cannot match.

The Core Principle: Thermal Conversion Without Oxygen

To understand the advantages of pyrolysis, it's essential to first grasp how it differs from burning. It is a thermochemical process that operates in a fundamentally different environment.

What is Pyrolysis?

Pyrolysis is the thermal decomposition of organic material at high temperatures (typically 300-600°C) in the complete or near-complete absence of oxygen.

Instead of burning the biomass to release heat, pyrolysis essentially "cooks" it. This process breaks down complex organic polymers like cellulose and lignin into simpler, smaller molecules that form the basis of its unique products.

The Three Key Products

The output of pyrolysis is a mix of solids, liquids, and gases, the proportions of which can be controlled by adjusting process conditions like temperature and heating rate.

- Bio-oil (Pyrolysis Oil): This liquid product is the hallmark of pyrolysis. It is an energy-dense, transportable liquid that can be stored for later use.

- Biochar: This is the solid, charcoal-like residue. It is rich in stable carbon and can be used as a fuel, but its highest value is often as a soil amendment.

- Syngas (Synthesis Gas): This is a mixture of non-condensable, combustible gases (like hydrogen, carbon monoxide, and methane).

Key Advantages Over Traditional Methods

The unique products of pyrolysis give it several distinct advantages over direct combustion (burning) for energy generation.

Product Versatility: Creating Value Beyond Heat

Directly burning biomass produces ash and hot flue gases, which are used to generate heat or steam. The value chain essentially ends there.

Pyrolysis, however, creates three separate value streams. Bio-oil can be refined into transportation fuels or chemicals, biochar can be sold for agricultural use, and syngas can be used to power the process itself, making it energy self-sufficient.

Energy on Demand: The Power of a Liquid Fuel

A major challenge with many renewable sources is intermittency. Raw biomass is also bulky and costly to transport.

Pyrolysis solves this by converting solid biomass into a storable and transportable liquid fuel. This decouples the location of biomass processing from the point of energy consumption, allowing energy to be generated where and when it is needed most.

Environmental Co-Benefits: Carbon Sequestration with Biochar

The biochar co-product is a key differentiator. When added to soil, it improves fertility, increases water retention, and, most importantly, sequesters carbon for centuries.

This turns a waste-to-energy process into a carbon-negative technology. Instead of releasing the carbon into the atmosphere via combustion, it is locked into a stable, solid form in the ground.

Enhanced Emission Control

Because pyrolysis occurs without oxygen, it prevents the formation of many pollutants commonly associated with incineration, such as dioxins and furans.

The process also allows for greater control over combustion, as the resulting fuels (bio-oil or syngas) can be burned in controlled systems like engines or turbines, leading to lower emissions of pollutants like nitrogen oxides (NOx) and sulfur oxides (SOx).

Understanding the Trade-offs and Challenges

While powerful, pyrolysis is not a perfect solution. An objective assessment requires understanding its practical limitations.

The Challenge of Bio-oil Quality

Raw bio-oil is not a "drop-in" replacement for petroleum fuels. It is acidic, corrosive, viscous, and chemically unstable over time.

Significant and often costly upgrading (such as hydrotreating) is required to transform it into a stable fuel compatible with existing infrastructure. This is a major technical and economic hurdle to its widespread adoption.

Feedstock Preparation Requirements

Pyrolysis reactors are sensitive to the physical properties of the feedstock. Biomass typically must be dried and ground to a uniform, small particle size before being processed.

This preparation step requires energy and adds to the overall operational cost and complexity of the facility compared to a simple combustion plant that can often handle more varied feedstock.

Capital Costs and Complexity

A pyrolysis plant, with its need for a sealed reactor, product collection systems, and potentially oil upgrading equipment, is generally more complex and has a higher upfront capital cost than a comparable biomass incinerator or boiler.

Making the Right Choice for Your Goal

The decision to use pyrolysis depends entirely on the desired outcome, as it offers a different value proposition than other biomass conversion technologies.

- If your primary focus is maximizing value and creating multiple products from waste: Pyrolysis is the superior choice due to its production of bio-oil and high-value biochar.

- If your primary focus is immediate, on-site heat and power at the lowest capital cost: Direct combustion is often the simpler and more established solution.

- If your primary focus is carbon sequestration and soil regeneration: The biochar co-product from pyrolysis makes it a uniquely compelling technology for achieving environmental goals.

Ultimately, pyrolysis empowers us to treat biomass not as waste to be disposed of, but as a raw material to be refined into a suite of valuable energy and carbon products.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Product Versatility | Creates three valuable products: bio-oil, biochar, and syngas. |

| Energy on Demand | Produces a storable, transportable liquid fuel (bio-oil). |

| Carbon Sequestration | Biochar co-product locks carbon in soil for centuries. |

| Enhanced Emission Control | Lower pollutant emissions compared to direct combustion. |

Ready to transform your biomass into valuable energy and materials?

Pyrolysis technology offers a sophisticated solution for laboratories and businesses aiming to maximize the value of organic waste. KINTEK specializes in providing high-quality lab equipment and consumables to support your pyrolysis research and development.

Whether you are exploring bio-oil refinement, biochar applications, or syngas utilization, our reliable tools can help you achieve precise and reproducible results. Let us help you unlock the full potential of biomass conversion.

Contact our experts today to discuss how KINTEK can support your specific laboratory needs and advance your sustainable energy projects.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds