The primary alternatives to traditional plastic waste management are a combination of systemic prevention, advanced chemical recycling, and energy recovery. While mechanical recycling remains a key component, true alternatives address the full lifecycle by prioritizing reduction and reuse, using chemical processes to handle complex waste, and, as a final option, converting non-recyclable plastic into energy.

The core challenge of plastic waste is not a lack of disposal options, but the failure of our linear "take-make-dispose" model. The most effective alternative is not a single technology, but a strategic shift to a circular economy, governed by a clear hierarchy of action that prioritizes preventing waste in the first place.

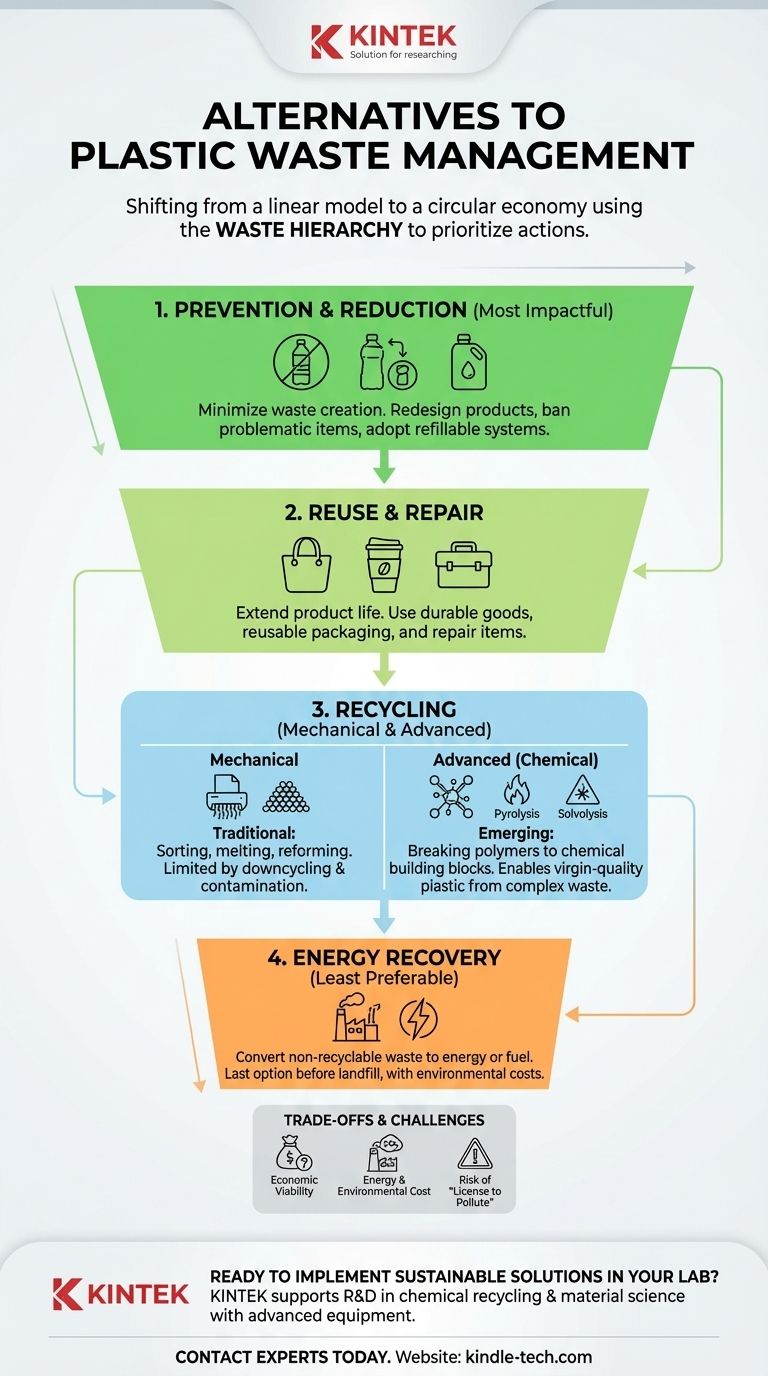

The Waste Hierarchy: A Framework for Effective Management

Instead of searching for a single "silver bullet," effective plastic management uses the waste hierarchy. This framework prioritizes strategies from most to least environmentally preferable, providing a logical path to reducing our plastic footprint.

Level 1: Prevention and Reduction (The Most Impactful Step)

The most effective way to manage plastic waste is to not create it. This upstream solution tackles the problem at its source, yielding the greatest environmental and economic benefits.

This involves redesigning products to use less plastic, banning problematic single-use items like bags and straws, and shifting business models toward refillable and reusable packaging systems.

Level 2: Reuse and Repair

This step focuses on extending the life of plastic products that are already in circulation. It is a simple but powerful way to decrease the demand for new virgin plastic production.

Common examples include using durable shopping bags, reusable water bottles and coffee cups, and choosing products designed for longevity and repairability over disposability.

Rethinking Recycling: Beyond the Basics

Recycling is not a monolithic activity. While the familiar form of mechanical recycling has significant limitations, emerging advanced methods offer new possibilities for creating a circular system.

Mechanical Recycling: The Traditional Approach

This is the process most people are familiar with: plastic waste is sorted, cleaned, shredded, melted, and reformed into new pellets.

Its primary limitation is downcycling. With each cycle, the plastic polymer degrades, resulting in lower-quality material. It is also highly sensitive to contamination and is only viable for a few specific types of clean plastic (like PET and HDPE).

Advanced (Chemical) Recycling: Breaking Down the Polymers

This is a set of emerging technologies that break plastics down into their original chemical building blocks. Instead of just melting plastic, it "un-bakes the cake," returning it to a more fundamental state.

Key methods include pyrolysis (using heat in the absence of oxygen) and gasification to create synthetic gas or oil, and solvolysis (using solvents) to break polymers back into monomers.

The major benefit is the ability to produce virgin-quality plastic from mixed, contaminated, or low-quality waste that is unsuitable for mechanical recycling. This enables true plastic-to-plastic circularity.

Energy Recovery: When Recycling Isn't an Option

For plastics that cannot be prevented, reused, or recycled, recovering their embedded energy is the next preferable step over sending them to a landfill.

Waste-to-Energy (Incineration)

In modern facilities, non-recyclable waste is combusted under controlled conditions to generate heat, which powers turbines to create electricity. This method effectively reduces the volume of waste destined for landfills.

Strict environmental controls are critical to capture and neutralize harmful pollutants and greenhouse gases generated during the process.

Pyrolysis for Fuel Production

The same pyrolysis technology used for advanced recycling can be tuned to produce a synthetic crude oil or gas. This "plastic-derived fuel" can then be used to power industrial furnaces, generators, or ships, offsetting the use of virgin fossil fuels.

Understanding the Trade-offs and Challenges

No solution is perfect. Acknowledging the limitations of each alternative is essential for making informed decisions and avoiding the pitfalls of greenwashing.

The Economic Viability Barrier

Advanced recycling and modern waste-to-energy plants require massive capital investment. Furthermore, the resulting products (new polymers or energy) must compete with a market dominated by historically cheap, subsidized fossil fuels.

The Energy and Environmental Cost

Both chemical recycling and incineration are energy-intensive processes with their own carbon footprint. While they solve one problem (waste), they can contribute to another (climate change) if not powered by clean energy and operated under stringent environmental regulations.

The Risk of a "License to Pollute"

An over-reliance on technological fixes like advanced recycling or incineration can create a moral hazard. It risks signaling to corporations and consumers that it's acceptable to continue producing and consuming single-use plastics because a high-tech "solution" exists downstream. Prevention and reduction must always remain the top priority.

The Complication of "Biodegradable" Plastics

So-called biodegradable or compostable plastics are not a simple solution. Most require specific conditions found only in industrial composting facilities and cannot break down in a landfill or the open environment. They also act as a major contaminant in conventional plastic recycling streams.

Making the Right Choice for Your Goal

Applying these alternatives requires a tailored approach depending on your role.

- If your primary focus is public policy: Prioritize "upstream" regulations that drive reduction, such as bans on non-essential single-use plastics and implementing Extended Producer Responsibility (EPR) schemes that make manufacturers financially responsible for their packaging waste.

- If your primary focus is business innovation: Invest in product redesign for reusability, explore refill-based business models, and commit to using high-quality recycled content to create a stable market for recycled materials.

- If your primary focus is individual impact: Rigorously follow the waste hierarchy—reduce your consumption first, reuse what you can, and only then recycle what is left, advocating for the brands and policies that do the same.

Ultimately, a multi-layered strategy that aggressively prioritizes reduction is the only viable path toward solving the global plastic waste crisis.

Summary Table:

| Alternative | Key Focus | Core Methods |

|---|---|---|

| Prevention & Reduction | Minimizing waste creation | Product redesign, bans on single-use plastics |

| Reuse & Repair | Extending product life | Reusable packaging, durable goods |

| Advanced Recycling | Chemical breakdown of plastics | Pyrolysis, gasification, solvolysis |

| Energy Recovery | Converting waste to energy | Waste-to-energy incineration, pyrolysis for fuel |

Ready to implement sustainable waste management solutions in your lab?

KINTEK specializes in providing advanced laboratory equipment and consumables that support research and development in chemical recycling, pyrolysis, and material science. Whether you're developing new polymers, testing recycled materials, or optimizing waste-to-energy processes, our reliable tools help you achieve accurate and efficient results.

Let us support your sustainability goals. Contact our experts today to find the right equipment for your plastic waste management research and innovation needs.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Benchtop Laboratory Vacuum Freeze Dryer

- Custom Machined and Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

- Benchtop Laboratory Freeze Dryer for Lab Use

People Also Ask

- What is the difference between DC and RF magnetron sputtering? Choose the Right Method for Your Materials

- What is the heating rate in sintering? A Guide to Optimizing Your Thermal Cycle for Quality Parts

- How is a hot air oven different? The Key is Forced Air for Uniform Heating

- How can we reduce the toxicity of carbon nanotubes? Strategies for Safer Applications

- What is the difference between oven and furnace in laboratory? Choose the Right Thermal Tool for Your Lab

- What role does convection play in heat transfer? Understanding Heat Movement in Fluids

- What are the principles of thin film? A Guide to Engineered Materials & Deposition Techniques

- What is the meaning of sintering? A Guide to High-Strength, Complex Part Manufacturing