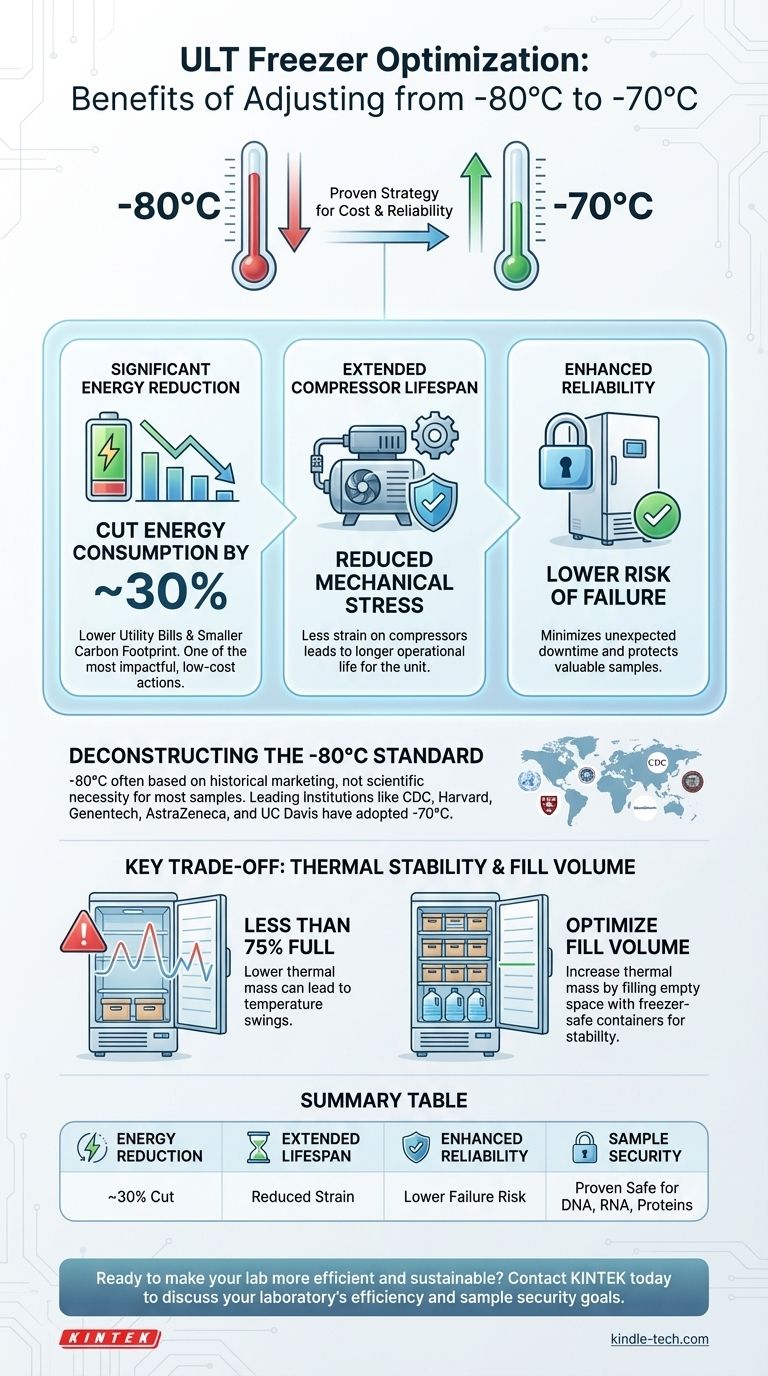

Adjusting an ultra-low temperature (ULT) freezer from -80°C to -70°C is a proven strategy for significantly reducing operational costs and improving equipment reliability. This 10°C change can cut energy consumption by approximately 30% and extend the freezer's lifespan, directly lowering the risk of mechanical failure and sample loss.

The widespread adoption of -80°C as a standard is largely a result of historical marketing, not a demonstrated scientific requirement for most common samples. Shifting to -70°C allows laboratories to achieve the same level of sample security while gaining substantial energy and financial savings.

The Tangible Benefits of a -70°C Setpoint

Moving to a -70°C setpoint delivers immediate, measurable advantages in energy use, equipment health, and operational stability. These benefits compound over the life of the freezer.

Significant Energy Reduction

The single greatest benefit is a dramatic drop in energy consumption, often around 30%. ULT freezers are among the most energy-intensive pieces of equipment in any laboratory.

This reduction in power draw translates directly into lower utility bills and a smaller carbon footprint for your institution.

Extended Compressor Lifespan

Maintaining -80°C places extreme and constant strain on a freezer's compressors. By raising the setpoint to -70°C, the system does not have to work as hard or cycle as frequently to maintain its target temperature.

This reduced mechanical stress mitigates wear and tear, leading to a longer operational lifespan for the entire unit.

Reduced Risk of Catastrophic Failure

A leading cause of sample loss is unexpected freezer failure. An over-stressed compressor is far more likely to fail, leading to costly downtime and the potential for compromised research.

By easing the burden on the freezer, a -70°C setpoint enhances reliability and provides greater peace of mind that your samples are secure.

Deconstructing the -80°C Standard

The assumption that -80°C is necessary for all long-term storage is worth questioning. The evidence suggests that -70°C is a safe and effective temperature for the vast majority of applications.

Is -80°C Scientifically Necessary?

The original ULT freezers were designed to operate at -70°C. The push toward -80°C in subsequent decades appears to be driven more by manufacturer competition than by new scientific evidence demonstrating its superiority for sample preservation.

For most common biological samples, including DNA, RNA, and proteins, there is no definitive data showing that storage at -80°C provides any additional benefit over -70°C.

The Institutional Precedent

This shift is not a speculative experiment; it is a validated practice adopted by leading scientific institutions and companies worldwide.

Organizations like the CDC, Harvard, Genentech, AstraZeneca, and UC Davis have already adjusted their ULT freezer fleets to -70°C, confirming its viability and reaping the benefits of energy efficiency and enhanced reliability.

Understanding the Key Trade-off: Thermal Stability

While the benefits are clear, there is one critical factor to consider before making the change: the freezer's fill volume. This directly impacts its ability to maintain a stable temperature.

The Impact of Freezer Capacity

A freezer's contents provide thermal mass, which helps buffer against temperature fluctuations when the door is opened. A fully stocked freezer will hold its temperature far more effectively than a partially empty one.

If a freezer is mostly empty, adjusting the setpoint to -70°C could lead to more significant temperature swings during daily use, potentially exposing samples to undesirable warming cycles.

Mitigation: Maximizing Fill Volume

If your freezer is not full, it is highly recommended to fill empty rack spaces before adjusting the temperature. Use ice-filled boxes, water jugs, or other freezer-safe containers to increase the thermal mass.

Alternatively, consider a freezer consolidation or sharing program with a neighboring lab to ensure units are run at or near capacity, maximizing both space and energy efficiency.

Making the Right Choice for Your Laboratory

Adopting a -70°C setpoint is a strategic decision that aligns fiscal responsibility with sustainable science. Base your decision on your primary operational goals.

- If your primary focus is cost savings and sustainability: Changing your ULT setpoints to -70°C is one of the most impactful, low-cost actions you can take.

- If your primary focus is sample integrity: -70°C is proven to be safe for most samples, and the reduced risk of mechanical failure offers an additional layer of long-term protection.

- If your freezers are consistently less than 75% full: First prioritize increasing the thermal mass by filling empty space or consolidating samples before adjusting the temperature setpoint.

Ultimately, shifting to -70°C is an evidence-based decision that makes your laboratory more efficient, economical, and secure.

Summary Table:

| Benefit | Key Impact |

|---|---|

| Energy Reduction | Cuts consumption by ~30%, lowering costs and carbon footprint. |

| Extended Lifespan | Reduces compressor strain, leading to longer equipment life. |

| Enhanced Reliability | Lowers the risk of catastrophic failure and sample loss. |

| Sample Security | -70°C is proven safe for most biological samples (DNA, RNA, proteins). |

Ready to make your lab more efficient and sustainable?

Adjusting your ULT freezers to -70°C is a simple change with major benefits. KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you implement this best practice to significantly reduce your energy bills and enhance the reliability of your sample storage.

Contact KINTEK today to discuss how we can support your laboratory's efficiency and sample security goals.

Visual Guide

Related Products

- 108L Vertical Ultra Low Temperature ULT Freezer

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 308L Precision Ultra Low Temperature Freezer for Laboratory Applications

- 708L Ultra Low Temperature Freezer High Performance Laboratory Freezer

- 208L Advanced Precision Laboratory Ultra Low Temperature Freezer for Cold Storage

People Also Ask

- What are the recommendations for storing mRNA vaccines in ultra-low temperature freezers? Ensure Absolute Stability at -80°C

- How is temperature controlled in ultra low temperature freezers? A Guide to Stable -80°C Storage

- How are advancements in compressor technology and refrigerant fluids improving ULT freezers? Boost Efficiency & Cut Costs

- What are ultra-low temperature freezers designed for? Preserving Your Most Valuable Biological Samples

- What temperature ranges are typically associated with ultra-low temperature freezers? Preserve Samples from -40°C to -86°C