At its core, converting plastic to fuel provides a method for managing problematic, non-recyclable plastic waste while simultaneously creating a valuable energy resource. This process, often called pyrolysis or chemical recycling, breaks down complex plastic polymers into simpler outputs like synthetic crude oil, gas, and char, which can then be refined or used as fuel.

While plastic-to-fuel technologies offer a compelling alternative to landfilling hard-to-recycle plastics, they are not a perfect solution. The key is to weigh the clear benefit of waste reduction against the significant technical and economic challenges, particularly the need to manage harmful emissions.

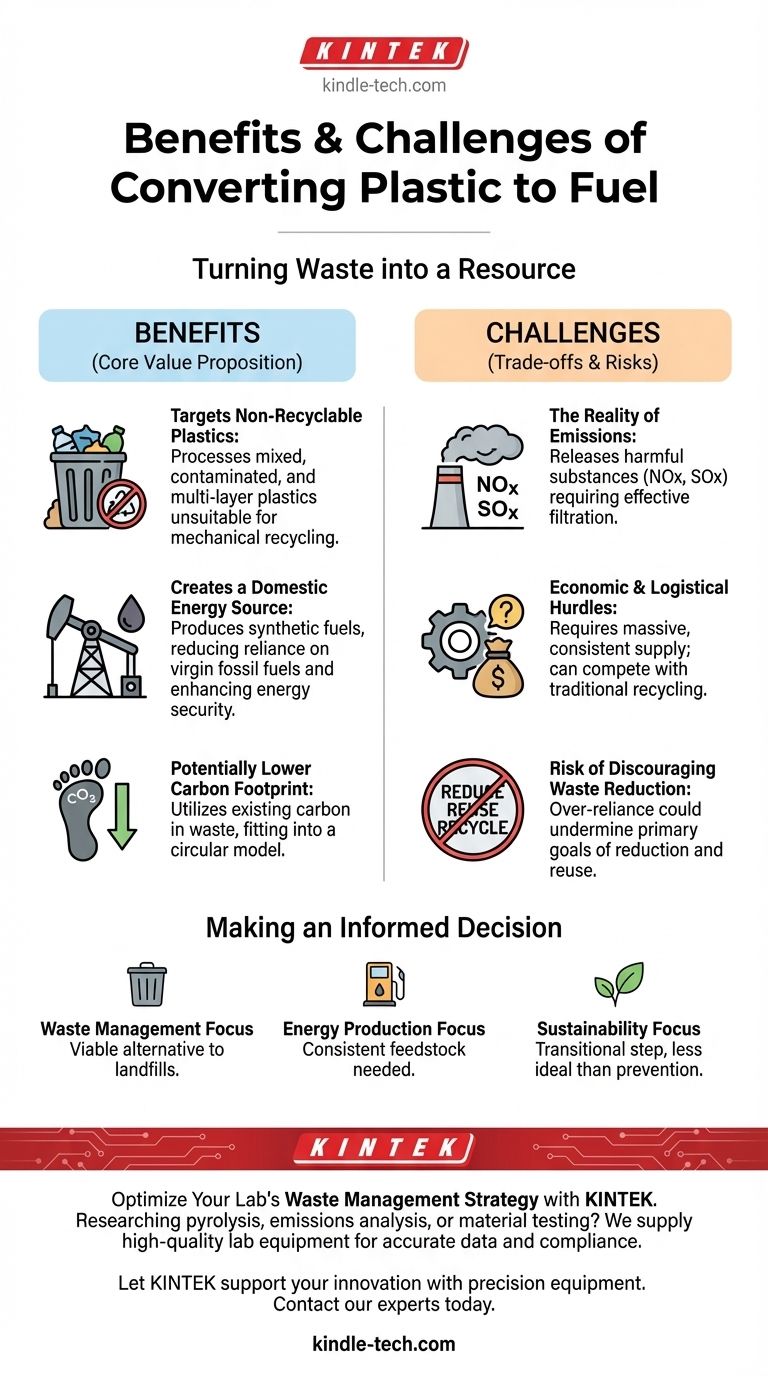

The Core Value Proposition: Turning Waste into a Resource

The primary appeal of plastic-to-fuel conversion lies in its ability to address two major global challenges simultaneously: plastic pollution and energy demand.

Targeting Non-Recyclable Plastics

The most significant benefit is the ability to process plastics that traditional mechanical recycling cannot handle. This includes mixed plastic streams, contaminated materials, and multi-layer films which would otherwise be sent to a landfill or incinerator.

This capability makes it a complementary tool in a waste hierarchy, targeting the materials left over after conventional recycling has taken place.

Creating a Domestic Energy Source

The synthetic fuels produced can be tailored for specific uses, including transportation fuels or chemical feedstocks. This creates a domestic source of energy from a readily available "above-ground" resource—our existing plastic waste.

This reduces reliance on extracting virgin fossil fuels and can contribute to a country's energy security.

Potentially Lower Carbon Footprint

When compared directly to extracting, refining, and burning new fossil fuels, using fuel derived from existing plastic can result in a lower overall carbon footprint.

The process utilizes the carbon already present in the waste stream, fitting into a more circular model, though it is not a zero-emission process.

Understanding the Trade-offs and Challenges

Objectivity requires acknowledging that plastic-to-fuel conversion is a complex industrial process with significant challenges that must be managed.

The Reality of Emissions

Contrary to some optimistic claims, the process is not emission-free. Burning any hydrocarbon, whether from petroleum or plastic, releases pollutants.

The conversion and combustion of these synthetic fuels can release harmful substances like nitrous oxides (NOx) and sulfur dioxides (SOx). Effective and often costly filtration and scrubbing technologies are essential to mitigate these health and environmental risks.

Economic and Logistical Hurdles

These facilities require a massive and consistent supply of plastic feedstock to be economically viable. This can lead to logistical challenges, such as importing waste from other regions.

Furthermore, creating a high-value market for waste-to-fuel can inadvertently compete with traditional recycling efforts, potentially diverting cleaner plastics away from more sustainable recycling pathways.

Risk of Discouraging Waste Reduction

There is a valid concern that an over-reliance on plastic-to-fuel could undermine the more critical goals of reducing plastic production and consumption in the first place.

If waste plastic becomes viewed primarily as a cheap fuel source, it may weaken the incentive for companies and consumers to pursue the most important strategies: reduce, reuse, and recycle.

Making an Informed Decision for Your Goal

The "best" approach depends entirely on the primary problem you are trying to solve. Consider these technologies as one tool in a much larger system.

- If your primary focus is waste management: Plastic-to-fuel is a viable alternative to landfills for contaminated and non-recyclable plastics, provided you invest in robust emissions control technology.

- If your primary focus is energy production: This technology can provide a localized fuel source, but its economic success depends on securing a consistent, low-cost supply of plastic feedstock without cannibalizing recycling streams.

- If your primary focus is environmental sustainability: View this technology as a transitional step. It is superior to landfilling plastic but less ideal than preventing plastic waste or using closed-loop mechanical recycling.

Ultimately, viewing plastic-to-fuel as one tool within a broader waste management strategy, rather than a standalone savior, is the key to its effective implementation.

Summary Table:

| Benefit | Challenge |

|---|---|

| Manages non-recyclable plastic waste | Emissions (NOx, SOx) require control |

| Creates fuel from waste (energy security) | High economic & logistical hurdles |

| Potentially lower carbon footprint vs. virgin fossil fuels | Risk of competing with recycling efforts |

Optimize Your Lab's Waste Management Strategy with KINTEK

Are you researching or developing plastic-to-fuel conversion processes? KINTEK specializes in supplying high-quality lab equipment and consumables essential for pyrolysis research, emissions analysis, and material testing. Our reliable tools help you accurately assess feedstock, monitor outputs, and ensure compliance with environmental standards.

We serve:

- Research laboratories developing waste-to-energy technologies

- Environmental testing facilities analyzing emissions and byproducts

- Universities and institutions studying circular economy solutions

Let KINTEK support your innovation with precision equipment that delivers accurate data for your plastic conversion projects. Contact our experts today to discuss your specific lab needs and how we can help you achieve your research goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Proton Exchange Membrane for Batteries Lab Applications

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

People Also Ask

- What is the effect of pressure in sputtering? Master Particle Energy for Superior Film Quality

- What is the structure of a pyrolysis plant? A Breakdown of the 4 Key Systems

- What is the major advantage of sputtering? Unmatched Material Versatility for High-Performance Thin Films

- Is biomass the best renewable energy source? Weighing Reliability Against Environmental Impact

- What are the limitations of physical vapor deposition? Overcoming the Line-of-Sight Challenge

- What are the physical properties of pyrolysis? Unlocking the Complex Nature of Pyrolysis Oil

- What is the difference between electric furnace and electric arc furnace? A Guide to Industrial Heating Methods

- What is the temperature and time for ashing? Achieve Accurate Results with the Right Parameters