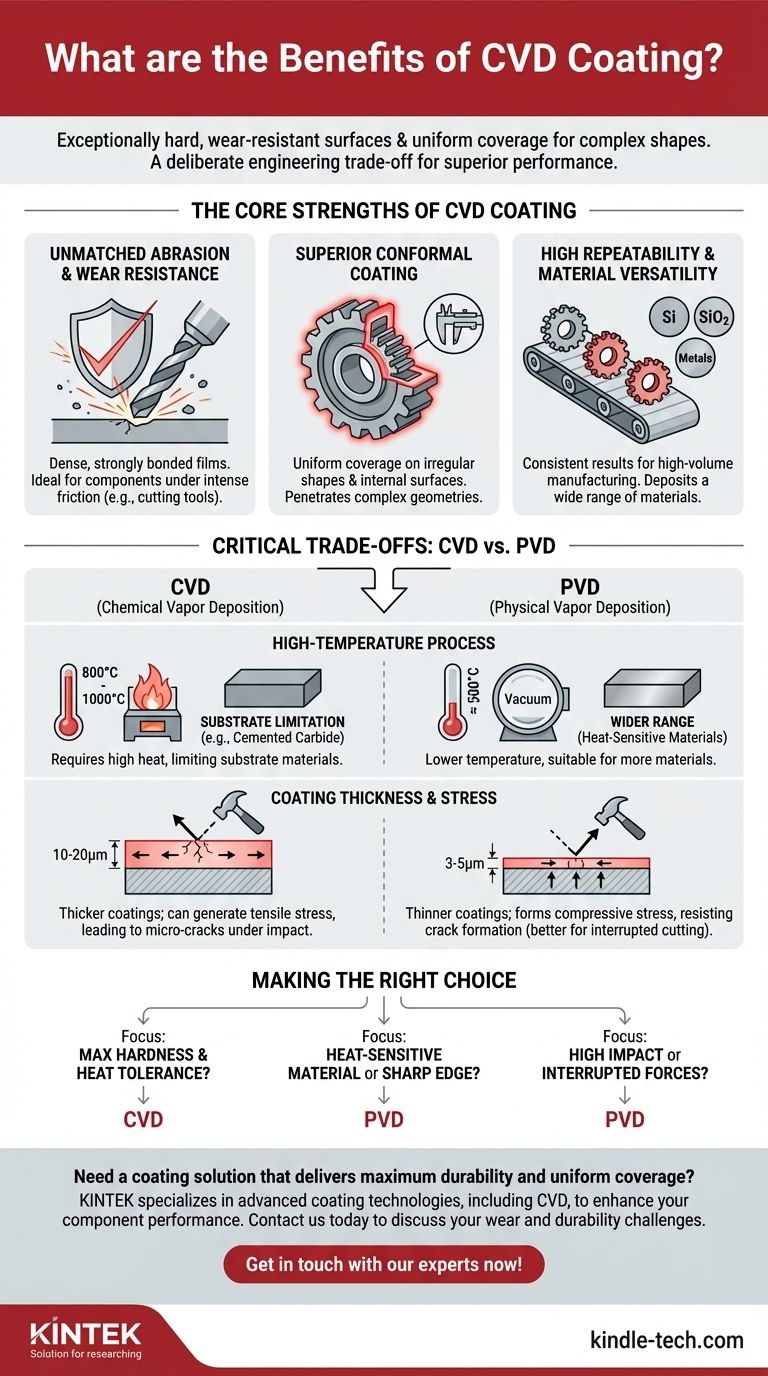

At its core, Chemical Vapor Deposition (CVD) coating excels at creating exceptionally hard, wear-resistant surfaces and providing uniform coverage on complex, irregular shapes. This process is highly valued for applications where durability and complete, even coating are the primary engineering goals, such as on cutting tools like drill bits and end mills.

The decision to use CVD is a deliberate engineering trade-off. You gain superior abrasion resistance and conformal coverage at the cost of a high-temperature process that limits which materials you can coat and can introduce internal stresses.

The Core Strengths of CVD Coating

The benefits of CVD stem directly from its unique deposition process, where chemical precursors react at high temperatures to form a solid film on a substrate's surface. This method results in distinct advantages for specific industrial applications.

Unmatched Abrasion and Wear Resistance

The primary benefit of a CVD coating is its outstanding resistance to abrasion and wear. The films created through this process are dense and strongly bonded to the substrate.

This makes CVD an ideal choice for components subjected to intense friction and abrasive forces, often outperforming other methods in pure durability tests.

Superior Conformal Coating

CVD is uniquely capable of coating irregularly shaped surfaces with high uniformity. This is often referred to as good "step coverage."

Because the coating is formed by a chemical reaction from a gas phase, it can penetrate and form evenly inside complex geometries, crevices, and internal surfaces where line-of-sight methods might fail.

High Repeatability and Material Versatility

The CVD process offers excellent repeatability, which is critical for high-volume manufacturing where consistency is paramount.

Furthermore, it is a highly versatile technique capable of depositing a wide range of materials, including dielectric films (like silicon dioxide), semiconductors, metals, and various metal organic compounds.

Understanding the Critical Trade-offs: CVD vs. PVD

To truly understand CVD's benefits, it's essential to compare it to its most common alternative, Physical Vapor Deposition (PVD). The differences are not about which is "better" but which is appropriate for a specific application.

The Challenge of High Temperatures

CVD is a high-temperature process, typically operating between 800°C and 1000°C. This heat is necessary to drive the chemical reactions.

The major consequence is that the substrate material must be able to withstand these temperatures without deforming or losing its properties. This limits CVD primarily to materials like cemented carbide. In contrast, PVD operates at much lower temperatures (around 500°C), making it suitable for a wider range of heat-sensitive materials.

The Impact of Coating Thickness and Stress

CVD coatings are generally thicker (10–20μm) than PVD coatings (3–5μm). While this thickness contributes to wear resistance, it can also create a problem.

During the cooling phase after deposition, this thick layer can generate significant tensile stress. This stress can lead to the formation of fine, microscopic cracks in the coating.

Under external impact or cyclical stress, such as in interrupted cutting processes like milling, these cracks can propagate and cause the coating to peel or flake off. PVD coatings, conversely, tend to form with compressive stress, which helps resist crack formation and makes them more suitable for such applications.

Making the Right Choice for Your Application

Selecting the correct coating technology requires a clear understanding of your component's material, its geometry, and its operational environment.

- If your primary focus is maximum hardness and wear resistance on a heat-tolerant part: CVD is an excellent choice due to its thick, durable, and well-bonded coating.

- If your primary focus is coating a heat-sensitive material or preserving a very sharp edge: The lower processing temperatures and thinner layers of PVD are the better solution.

- If your primary focus is performance in an application with high impact or interrupted forces: PVD is often preferred because its compressive stress resists the formation of cracks that can lead to coating failure.

Ultimately, understanding these fundamental process differences is the key to selecting the coating that truly enhances your component's performance and lifespan.

Summary Table:

| Benefit | Key Characteristic | Best For |

|---|---|---|

| Unmatched Wear Resistance | Dense, strongly bonded films | Cutting tools, components under intense friction |

| Superior Conformal Coating | Uniform coverage on complex geometries | Parts with crevices and internal surfaces |

| High Repeatability & Versatility | Consistent results; wide range of materials | High-volume manufacturing |

| Critical Trade-off | Consideration | Alternative |

| High-Temperature Process | Limits substrate materials (e.g., cemented carbide) | PVD for heat-sensitive materials |

| Thick Coatings & Tensile Stress | Potential for micro-cracks under impact | PVD for interrupted cutting processes |

Need a coating solution that delivers maximum durability and uniform coverage?

KINTEK specializes in advanced coating technologies, including CVD, to enhance the performance and lifespan of your critical components. Our expertise ensures you get the right coating for your specific material, geometry, and operational demands.

Contact us today to discuss how our CVD coating services can solve your wear and durability challenges. Let's optimize your component's performance together.

Get in touch with our experts now!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate