The primary benefits of a plastic pyrolysis plant are its ability to convert problematic plastic waste into valuable resources, drastically reduce the volume of material sent to landfills, and create alternative energy sources. This process chemically recycles plastics that traditional mechanical recycling methods often cannot handle, addressing a critical gap in waste management.

The core value of plastic pyrolysis is its power to transform a linear waste problem into a circular resource loop. It turns an environmental liability—non-recyclable plastic—into valuable assets like fuel oil and carbon black, fundamentally changing how we view and manage plastic waste.

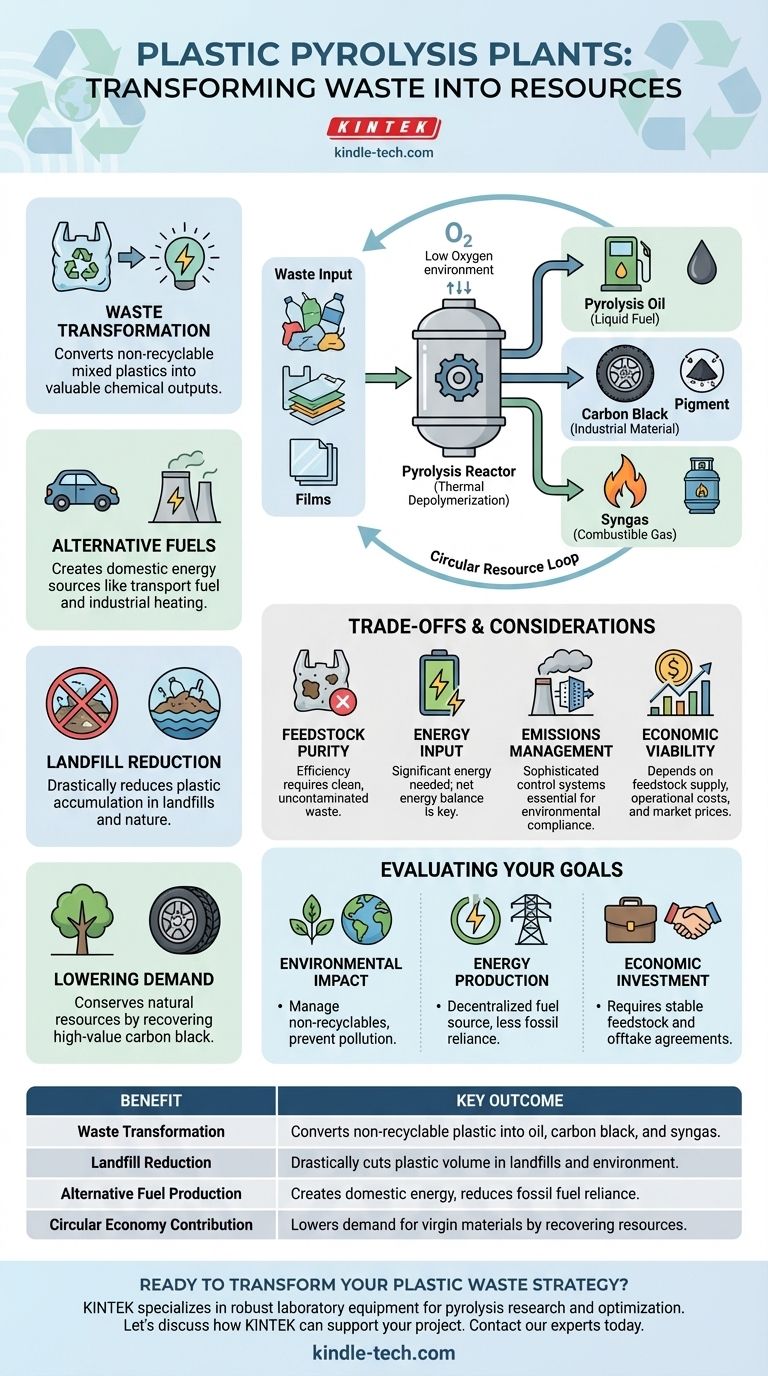

The Core Benefits of Plastic Pyrolysis

A pyrolysis plant uses a process called thermal depolymerization. In a controlled, low-oxygen environment, high heat breaks down the long polymer chains in plastic into smaller, more valuable molecules without combustion.

Transforming Waste into Valuable Resources

The process converts mixed and often low-grade plastic waste into several useful outputs. This act of chemical recycling reclaims the inherent value locked within the plastic.

The primary outputs are pyrolysis oil (a synthetic fuel), carbon black (a valuable industrial material), and syngas (a combustible gas).

Producing Alternative Fuels

The main liquid product, pyrolysis oil, can be refined and used as a transportation fuel or for industrial heating. This creates a domestic energy source from a widely available waste stream.

This provides a direct alternative to extracting and refining virgin fossil fuels, contributing to greater energy independence and resource security.

Reducing Landfill and Environmental Burden

Pyrolysis plants can process plastics that are typically rejected by conventional recycling facilities, such as mixed plastic films, multi-layered packaging, and contaminated items.

By diverting this material, pyrolysis directly reduces the amount of plastic accumulating in landfills and leaking into natural ecosystems like oceans and rivers.

Lowering Demand for Virgin Materials

The carbon black produced is a high-value solid material used in manufacturing tires, inks, and pigments.

Recovering this material from waste plastic reduces the need to produce it from fossil fuels, contributing to a more circular economy and conserving natural resources.

Understanding the Trade-offs and Considerations

While powerful, pyrolysis technology is not a silver bullet. An objective evaluation requires understanding its operational realities and challenges.

Feedstock Purity is Critical

The efficiency of the process and the quality of the outputs are highly dependent on the type and cleanliness of the incoming plastic waste. Contaminants like PVC, PET, dirt, and metal can disrupt operations and degrade the final products.

Energy Input Requirements

Pyrolysis is an endothermic process, meaning it requires a significant and consistent energy input to maintain the high temperatures needed to break down plastics.

A plant's overall environmental and economic viability depends on its net energy balance—ensuring it produces more energy than it consumes. The syngas generated during the process is often reused to help power the facility.

Emissions and Byproduct Management

Like any industrial thermal process, a pyrolysis plant generates emissions that must be managed with sophisticated control systems. Ensuring that the facility captures and treats all volatile compounds and particulates is essential for its environmental license to operate.

Economic Viability Hinges on Markets

The profitability of a pyrolysis plant depends on three key factors: a consistent supply of low-cost (or free) plastic feedstock, efficient operational costs, and stable markets for its outputs. Fluctuations in the price of crude oil can directly impact the market value of pyrolysis oil.

How to Evaluate Pyrolysis for Your Goals

Your assessment of plastic pyrolysis depends entirely on your primary objective.

- If your primary focus is environmental impact: The key benefit is its unique ability to manage non-recyclable plastics, preventing them from ending up in landfills or the ocean.

- If your primary focus is energy production: Pyrolysis offers a decentralized method to convert a local waste stream into a usable fuel, reducing reliance on conventional fossil fuels.

- If your primary focus is economic investment: A successful plant requires securing a long-term, consistent feedstock and establishing stable offtake agreements for the pyrolysis oil and carbon black.

Ultimately, plastic pyrolysis represents a powerful tool in a circular economy, offering a pragmatic way to reclaim value from our most challenging waste streams.

Summary Table:

| Benefit | Key Outcome |

|---|---|

| Waste Transformation | Converts non-recyclable plastic into pyrolysis oil, carbon black, and syngas. |

| Landfill Reduction | Drastically cuts plastic waste volume sent to landfills and the environment. |

| Alternative Fuel Production | Creates a domestic energy source, reducing reliance on virgin fossil fuels. |

| Circular Economy Contribution | Lowers demand for virgin materials by recovering valuable industrial resources. |

Ready to transform your plastic waste management strategy?

A plastic pyrolysis plant is a significant investment in sustainability and resource recovery. At KINTEK, we specialize in providing robust laboratory equipment and consumables to help you research, test, and optimize pyrolysis processes. Whether you are developing new catalysts, analyzing feedstock, or verifying output quality, our solutions support your journey toward a circular economy.

Let's discuss how KINTEK can support your pyrolysis project. Contact our experts today to find the right equipment for your lab's needs.

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Non Consumable Vacuum Arc Induction Melting Furnace

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What role does an autoclave play in simulating PWR conditions? Advanced Material Validation for Nuclear Safety

- Why are sealed laboratory reaction vessels necessary in the hydrothermal synthesis of zeolites? Ensure Purity and Yield

- Why are high-pressure autoclaves essential for preparing bio-based polyamide curing agents from dimeric acid?

- What is the purpose of using a high-temperature hydrothermal reactor? Enhance Iodine@Activated Carbon Cathode Synthesis

- What is the purpose of using high-purity argon gas in a high-pressure reactor? Ensure Precise Corrosion Test Data