The primary benefit of vacuum pyrolysis is its ability to produce a higher yield of high-quality liquid bio-oil compared to other methods. By operating under reduced pressure, the process lowers the decomposition temperature of organic materials and rapidly removes valuable vapors, preventing them from breaking down into less desirable gases and char.

While all pyrolysis converts waste into value, vacuum pyrolysis is specifically engineered to maximize the quantity and quality of liquid bio-oil by precisely controlling the reaction environment. It achieves this by lowering the process temperature and preventing the secondary reactions that degrade the final product.

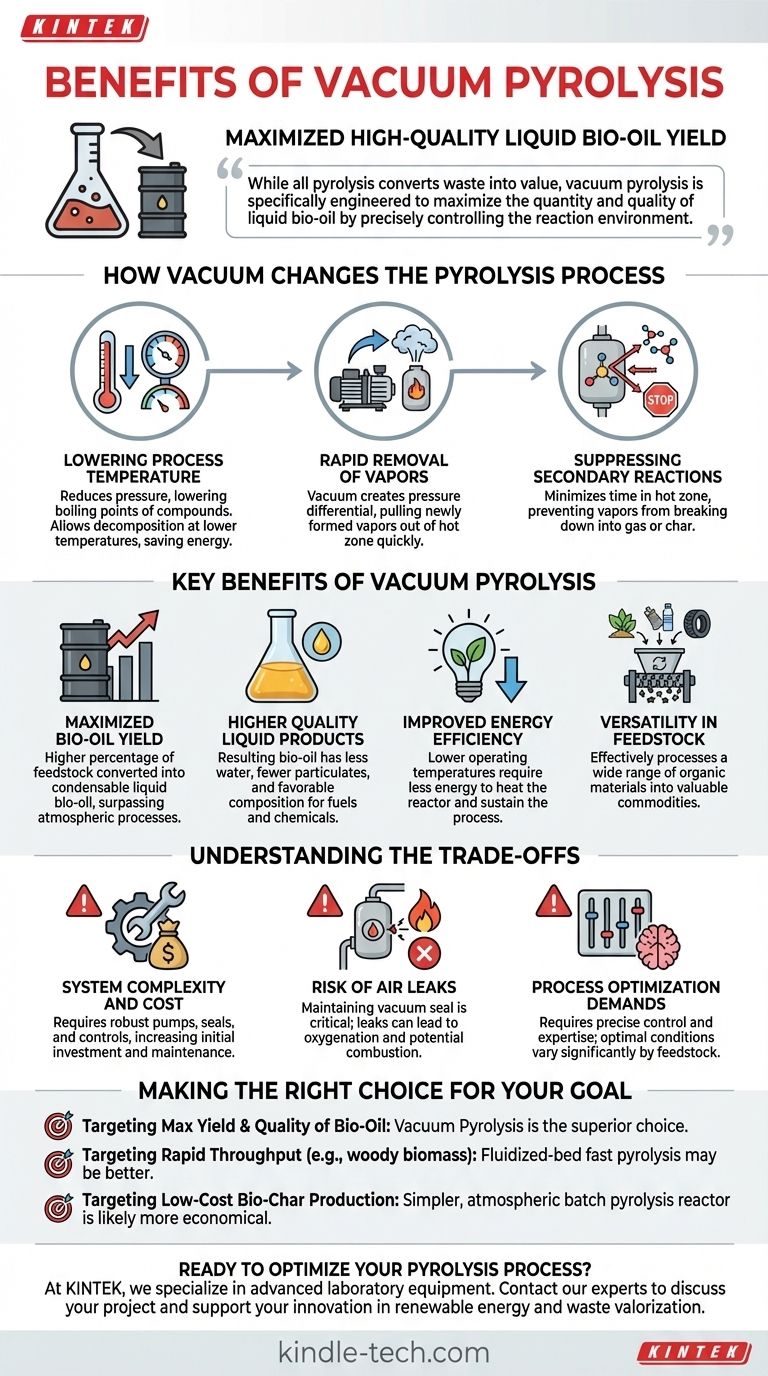

How Vacuum Changes the Pyrolysis Process

To understand the benefits, we must first understand the core principle. Pyrolysis is the thermal decomposition of materials in the absence of oxygen. Adding a vacuum fundamentally alters the physics of this process.

Lowering the Process Temperature

Applying a vacuum reduces the pressure inside the reactor. This, in turn, lowers the boiling point of the chemical compounds (pyrolysates) created during decomposition.

Just as water boils at a lower temperature on a high mountain, organic materials in a vacuum reactor decompose and vaporize at a lower temperature than they would at atmospheric pressure. This directly translates to reduced energy consumption for the system.

Rapid Removal of Vapors

The pressure differential created by the vacuum actively pulls the newly formed vapors out of the hot reaction zone almost immediately.

This rapid extraction is a critical advantage. In standard pyrolysis, these valuable vapors linger in the reactor, where the high heat can cause them to "crack" or re-polymerize into less useful products.

Suppressing Secondary Reactions

The combination of lower temperatures and rapid vapor removal works to suppress unwanted secondary reactions. This is the key to producing a cleaner, more valuable end product.

By minimizing the time vapors spend in the hot zone, you prevent them from breaking down into non-condensable gases or forming excess char. The result is a process that preferentially yields the most valuable liquid fraction.

The Key Benefits of Vacuum Pyrolysis

The unique physics of the vacuum process leads to several distinct operational advantages over atmospheric or conventional fast pyrolysis.

Maximized Bio-Oil Yield

This is the most significant benefit. By preventing secondary reactions, a much larger percentage of the initial feedstock is converted into condensable, liquid bio-oil. Yields are consistently higher than in atmospheric processes.

Higher Quality Liquid Products

The resulting bio-oil is often of higher quality. It typically contains less water, fewer solid particulates, and a more favorable composition for upgrading into transportation fuels or specialty chemicals.

Improved Energy Efficiency

Operating at lower temperatures means less energy is required to heat the reactor and sustain the process. This can lead to significant operational cost savings and a better net energy balance for the entire system.

Versatility in Feedstock

Like other pyrolysis methods, vacuum pyrolysis is highly flexible. It can effectively process a wide range of organic materials, including plastics, waste tires, and diverse forms of biomass, converting them into valuable commodities.

Understanding the Trade-offs

No technology is without its challenges. Objectivity requires acknowledging the trade-offs associated with the vacuum approach.

System Complexity and Cost

Introducing a vacuum system adds complexity. It requires robust vacuum pumps, high-integrity seals, and sophisticated control systems to maintain sub-atmospheric pressure, which increases both the initial capital investment and ongoing maintenance costs.

Risk of Air Leaks

Maintaining the integrity of the vacuum seal is critical. Any air leaking into the hot reactor can create an oxygenated environment, leading to unintended combustion. This is not only inefficient but can also pose a significant safety hazard.

Process Optimization Demands

Vacuum pyrolysis is not a one-size-fits-all solution. The optimal level of vacuum and temperature profile can vary significantly depending on the feedstock. Achieving peak performance requires more precise process control and expertise than simpler pyrolysis systems.

Making the Right Choice for Your Goal

The decision to use vacuum pyrolysis should be driven by your specific end-product requirements and economic constraints.

- If your primary focus is maximizing the yield and quality of liquid bio-oil: Vacuum pyrolysis is the superior technical choice, as it is specifically designed for this outcome.

- If your primary focus is rapid throughput for a consistent feedstock like woody biomass: A fluidized-bed fast pyrolysis system may offer a more practical and scalable solution.

- If your primary focus is low-cost production of bio-char with liquids as a secondary product: A simpler, atmospheric batch pyrolysis reactor is likely the most economical path.

Ultimately, selecting the right thermal conversion technology depends on a clear understanding of your goals, feedstock, and operational capabilities.

Summary Table:

| Benefit | Key Advantage |

|---|---|

| Maximized Bio-Oil Yield | Higher liquid product conversion by preventing secondary reactions. |

| Superior Product Quality | Bio-oil with less water, fewer solids, and a better chemical composition. |

| Improved Energy Efficiency | Lower operating temperatures reduce energy consumption. |

| Feedstock Versatility | Effectively processes biomass, plastics, and waste tires. |

Ready to optimize your pyrolysis process for maximum liquid yield and quality?

At KINTEK, we specialize in advanced laboratory equipment, including pyrolysis systems. Our expertise can help you select or develop the right thermal conversion technology to meet your specific goals for bio-oil, char, or syngas production.

We provide solutions for laboratories and R&D teams focused on converting biomass, plastics, and other organic waste into valuable commodities. Let us help you enhance your research and development with reliable, efficient equipment.

Contact our experts today to discuss your project and discover how KINTEK can support your innovation in renewable energy and waste valorization.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1700℃ Muffle Oven Furnace for Laboratory

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Vacuum Cold Trap Direct Cold Trap Chiller

- CF Ultra-High Vacuum Observation Window Stainless Steel Flange Sapphire Glass Sight Glass

People Also Ask

- What is the bias of sputtering RF? How a Negative DC Self-Bias Enables Insulator Sputtering

- What are the hazards of additive manufacturing? Mitigate Chemical, Physical, and Mechanical Risks

- How does a controlled heating reaction system achieve morphology control for platinum nanoparticles?

- What is the unit of measurement for coating thickness? Microns (μm) and Nanometers (nm) Explained

- How do ultrasonic cell disruptors or dispersion equipment function during ZIF-8 synthesis? Master Acoustic Cavitation

- What are rapid sintering techniques? Unlock Faster, Stronger Material Production

- What is the role of the constant flow and constant pressure pump in core flooding? Master Deep Granite Stimulation

- How do you clean a sputtering chamber? Master the Critical Protocol for Purity and Yield