The "best" crucible is the one that perfectly matches your specific application. There is no single universal solution. The ideal choice depends entirely on the metal you are melting, the maximum temperature you need to reach, and the type of furnace you are using. The three most common and important types you will encounter are clay-graphite, silicon carbide, and pure graphite.

Choosing the right crucible isn't about finding a single superior product, but about understanding the critical relationship between your material, your heat source, and the crucible's composition. Getting this match right is the key to safe, efficient, and successful high-temperature work.

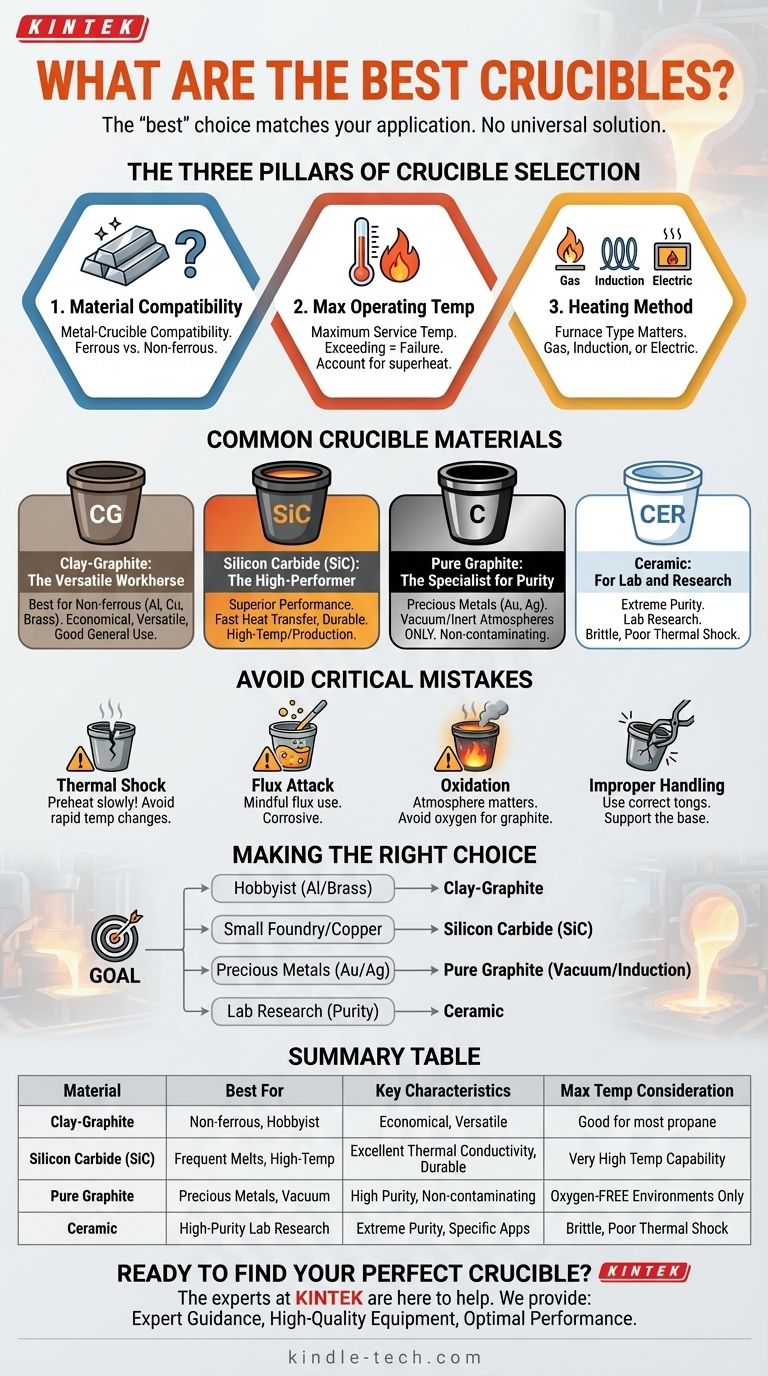

The Three Pillars of Crucible Selection

To select the correct crucible, you must evaluate your needs based on three fundamental criteria. Mismatching any of these can lead to failed melts, damaged equipment, or dangerous failures.

Pillar 1: Material Compatibility

The metal you intend to melt dictates which crucible material is chemically compatible.

A primary distinction is between ferrous (iron-based) and non-ferrous metals (aluminum, copper, brass, precious metals). Some crucibles that are excellent for aluminum will degrade quickly when used for cast iron.

Pillar 2: Maximum Operating Temperature

Every crucible has a maximum service temperature. Exceeding this limit will cause the crucible to soften, sag, or fail completely.

Always choose a crucible rated for a temperature significantly higher than the melting point of your target metal. Remember to account for the superheating required to ensure the metal is fluid enough for casting.

Pillar 3: Heating Method

The way you apply heat is a critical factor. The main types of furnaces each have specific requirements.

- Gas/Propane Furnaces: These are common and work well with most crucible types, especially clay-graphite and silicon carbide.

- Induction Furnaces: These require a crucible that is either electrically conductive (like graphite or silicon carbide) to heat up directly, or a non-conductive crucible (like a ceramic) placed inside a conductive graphite susceptor.

- Electric Resistance Furnaces: These function like a kiln and can use a wide variety of crucible types.

A Breakdown of Common Crucible Materials

Understanding the properties of each material is the final step in making an informed decision.

Clay-Graphite: The Versatile Workhorse

These are the most common and economical crucibles, often black or dark gray in color. They are a composite of graphite, silicon carbide, and clay binders.

They are the standard choice for melting most non-ferrous metals, including aluminum, brass, bronze, and copper alloys. They offer a good balance of durability and cost for general-purpose foundry work.

Silicon Carbide (SiC): The High-Performer

Silicon carbide crucibles offer superior performance over clay-graphite. They have excellent thermal conductivity, which means they transfer heat to the metal charge much faster, resulting in shorter melt times and better energy efficiency.

SiC crucibles are more resistant to thermal shock and chemical attack. This makes them a better choice for demanding production environments and for melting higher-temperature alloys, including some ferrous metals.

Pure Graphite: The Specialist for Purity

As the name implies, these are made from high-purity graphite. Their primary use is in vacuum or inert-atmosphere furnaces.

They are the top choice for melting precious metals like gold and silver, as they are non-contaminating and have a reducing effect that helps prevent oxidation of the melt. Crucially, they cannot be used in an oxygen-rich atmosphere (like a propane furnace), as the graphite will rapidly oxidize and burn away above 900°F (approx. 480°C).

Ceramic Crucibles: For Lab and Research

Materials like fused silica, alumina, and zirconia are used for highly specific laboratory applications where extreme purity is paramount or where the melt is highly reactive.

These crucibles are typically very brittle, have poor resistance to thermal shock, and are not suited for the mechanical stress of a typical foundry environment.

Critical Mistakes and How to Avoid Them

A crucible's lifespan is determined as much by its use as by its composition. Avoiding these common errors is essential.

The Danger of Thermal Shock

This is the number one cause of crucible failure. Rapid, uneven changes in temperature create stress that cracks the material.

Always preheat a new or stored crucible slowly and thoroughly to drive out any absorbed moisture. Never drop a cold ingot or tool into a red-hot crucible.

Chemical Attack from Flux

Fluxes are used to clean impurities from a melt, but they can be highly corrosive. Aggressive fluxes can eat away at the crucible's interior wall, drastically shortening its life.

Be mindful of the type and amount of flux you use. Choose a crucible material, like silicon carbide, that offers better resistance if you use flux regularly.

The Risk of Oxidation

This primarily affects pure graphite crucibles used improperly in open-air furnaces. However, all graphite-bearing crucibles will eventually oxidize and degrade from exposure to flame and air at high temperatures. A protective glaze on clay-graphite and SiC crucibles helps mitigate this.

Improper Handling

Crucibles are strong at resisting heat but brittle against mechanical shock. Always use properly fitting tongs that support the crucible's base and grip it securely around the body. Never "pinch" a crucible from the top rim.

Making the Right Choice for Your Goal

- If you are a hobbyist melting aluminum or brass: A standard clay-graphite crucible offers the best combination of performance and value.

- If you run a small foundry with frequent melts or work with copper alloys: Investing in a silicon carbide (SiC) crucible will pay off with faster melts and a longer service life.

- If you are melting or refining precious metals (gold, silver): A pure graphite crucible is the correct choice, but only for use in an electric, vacuum, or induction furnace.

- If you are conducting high-purity lab research: A ceramic crucible (alumina, zirconia) is necessary to prevent contamination of your sample.

Selecting the right crucible is the foundation of successful and safe metallurgical work.

Summary Table:

| Crucible Material | Best For | Key Characteristics | Max Temp Consideration |

|---|---|---|---|

| Clay-Graphite | Non-ferrous metals (Al, Cu, brass); hobbyists | Economical, versatile, good for general use | Good for most propane furnaces |

| Silicon Carbide (SiC) | Frequent melts, higher-temp alloys, small foundries | Excellent thermal conductivity, durable, flux-resistant | Very high temperature capability |

| Pure Graphite | Precious metals (Au, Ag); vacuum/inert atmospheres | High purity, non-contaminating, reducing atmosphere | Must be used in oxygen-free environments |

| Ceramic (Alumina, etc.) | High-purity lab research, reactive materials | Extreme purity, highly specific applications | Brittle, poor thermal shock resistance |

Ready to Find Your Perfect Crucible?

Choosing the right crucible is critical for the safety, efficiency, and success of your work. The experts at KINTEK are here to help you navigate these choices.

We provide:

- Expert Guidance: Get personalized recommendations based on the metal you're melting, your furnace type, and your operational goals.

- High-Quality Lab Equipment: KINTEK supplies reliable crucibles and consumables, including clay-graphite, silicon carbide, and graphite options, tailored to your laboratory or foundry needs.

- Optimal Performance: Ensure your melting process is safe, efficient, and delivers consistent results with the right equipment.

Don't leave your results to chance. Contact our specialists today for a consultation and let us help you select the ideal crucible for your specific application.

[#ContactForm Contact KINTEK Now]

Visual Guide

Related Products

- High Purity Pure Graphite Crucible for Electron Beam Evaporation

- High Purity Pure Graphite Crucible for Evaporation

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Custom Machined and Molded PTFE Teflon Parts Manufacturer with PTFE Crucible and Lid

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

People Also Ask

- What is the melting point of crucible material? Choose the Right Crucible for Your Process

- Why are high-chemical-stability ceramic crucibles essential for molten carbonate impregnation? Secure Pure Membranes

- Why are alumina crucibles or baskets essential for Boudouard reaction studies? Ensure Pure Data & Chemical Inertness

- What are crucibles used for in the laboratory? Essential Tools for High-Temperature Processing

- What metal is best for a crucible? Match Your Material to the Perfect Crucible for Superior Melts

- What are the specific functions of alumina crucibles during LLZO sintering? Boost Ionic Conductivity & Phase Stability

- What can you do with a crucible? Unlock High-Temperature Melting for Metals, Glass, and More

- Why are high-purity alumina crucibles selected for oxidation tests? Ensure Precision at 1200°C for Fe-Cr-Al ODS Alloys