The most common catalysts for plastic pyrolysis are a class of materials known as zeolites, particularly ZSM-5, as well as various metal oxides and mesoporous silicates. Their primary function is to lower the extreme temperatures required for pyrolysis and to selectively "crack" long plastic polymer chains into smaller, more valuable liquid fuel molecules. This catalytic action is critical for making the process more energy-efficient and for controlling the chemical composition of the final oil product.

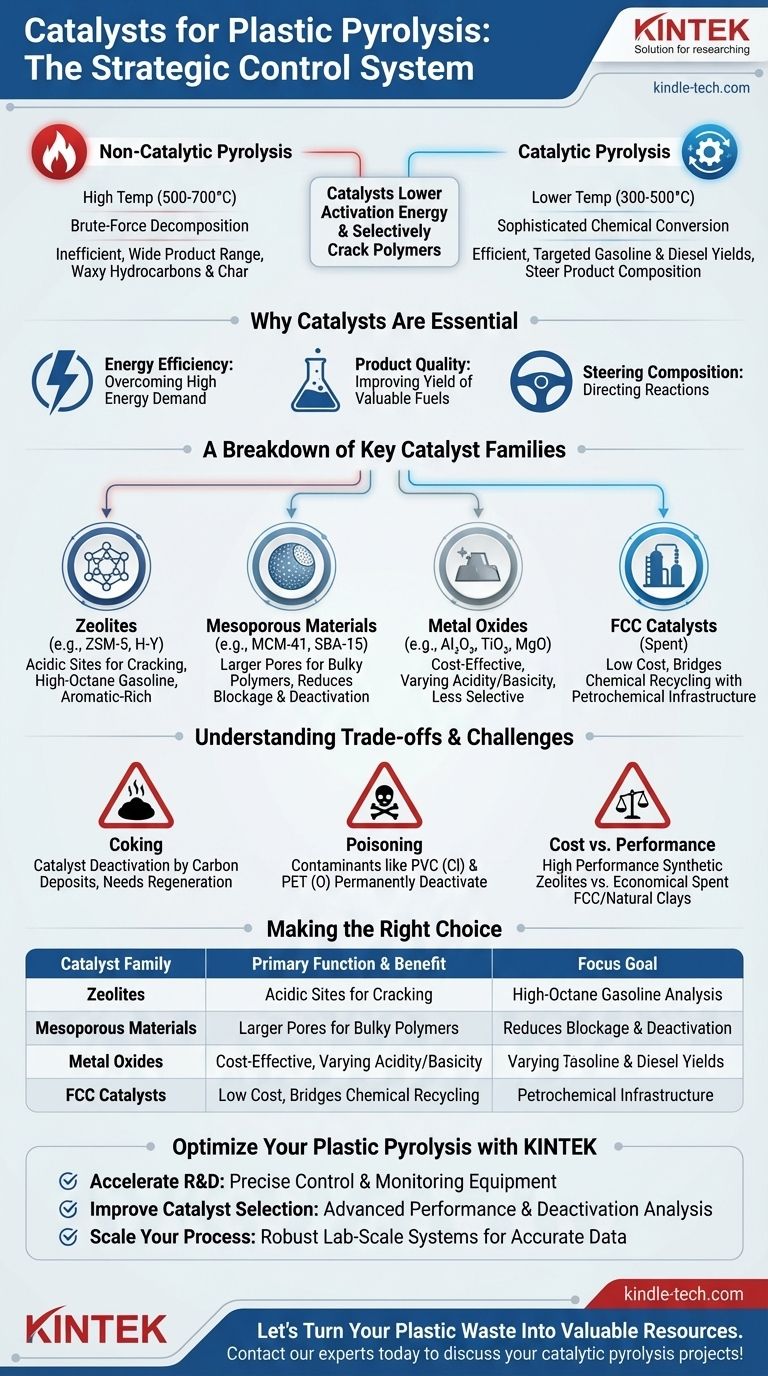

Catalysts are the strategic control system for plastic pyrolysis. While non-catalytic pyrolysis simply melts and decomposes plastic, catalytic pyrolysis allows you to actively direct the chemical reactions to produce specific, higher-value fuels more efficiently and at lower energy cost.

Why Catalysts Are Essential in Pyrolysis

Thermal, or non-catalytic, pyrolysis can convert plastic to oil, but it is an inefficient, brute-force method. Introducing a catalyst transforms the process from a simple decomposition into a sophisticated chemical conversion.

Overcoming High Energy Demand

Non-catalytic pyrolysis requires very high temperatures, often exceeding 500-700°C, to break the strong chemical bonds in polymers. Catalysts provide an alternative reaction pathway with a lower activation energy, allowing the process to run effectively at lower temperatures (e.g., 300-500°C), which significantly reduces energy consumption and operational costs.

Improving Product Quality and Yield

Without a catalyst, pyrolysis often produces a wide, undesirable range of products, including heavy, waxy hydrocarbons and excessive char. Catalysts promote specific cracking reactions that break these heavy molecules into the more valuable gasoline (C5-C12) and diesel (C13-C22) range hydrocarbons, increasing the yield of usable liquid fuel.

Steering Product Composition

Different catalysts can steer the reaction toward different outcomes. For instance, some are excellent at producing aromatic compounds, which increase the octane number of gasoline. Others may favor the production of olefins, which are valuable feedstocks for the chemical industry.

A Breakdown of Key Catalyst Families

No single catalyst is perfect for all plastics or all desired outcomes. The choice depends on the type of plastic feedstock and the target product.

Zeolites (e.g., ZSM-5, H-Y)

Zeolites are the most widely studied and effective catalysts for plastic pyrolysis. They are crystalline aluminosilicates with a highly ordered, porous structure and strong acidic sites. These sites are exceptional at cracking long hydrocarbon chains. ZSM-5, with its specific pore size, is particularly effective at producing high-octane, aromatic-rich gasoline.

Mesoporous Materials (e.g., MCM-41, SBA-15)

While zeolites are highly effective, their small micropores can become blocked by bulky plastic molecules, leading to deactivation. Mesoporous materials have much larger pores, allowing them to process larger polymers more effectively before they are broken down into smaller fragments that can then be further refined.

Metal Oxides (e.g., Al₂O₃, TiO₂, MgO)

Simple metal oxides are often used as catalysts or as supports for other active metals. They possess varying degrees of acidity and basicity that can influence the product distribution. They are generally less expensive than zeolites but may also be less selective in the products they form.

Fluid Catalytic Cracking (FCC) Catalysts

These are catalysts used extensively in traditional oil refineries. Spent FCC catalysts, which have lost some activity but are available at a very low cost, have proven to be highly effective for plastic pyrolysis. Using them creates a powerful link between chemical recycling and existing petrochemical infrastructure.

Understanding the Trade-offs and Challenges

While catalysts offer immense benefits, they also introduce complexities and challenges that must be managed for a successful industrial operation.

Catalyst Deactivation by Coking

The most significant operational challenge is coking. During pyrolysis, carbonaceous deposits (coke) form on the surface of the catalyst, covering the active sites and rendering it ineffective over time. The catalyst must then be regenerated, typically by burning off the coke in a controlled manner.

Poisoning from Contaminants

Plastic waste is rarely pure. Contaminants can "poison" the catalyst, permanently deactivating it. For example, chlorine from PVC plastic can destroy the acidic sites on zeolites, while oxygen from PET can lead to unwanted reactions and rapid deactivation.

Cost vs. Performance

There is a direct trade-off between the cost of a catalyst and its performance. Highly engineered synthetic zeolites offer superior selectivity and activity but come at a high price. Cheaper alternatives, like natural clays or spent FCC catalysts, may offer lower performance but can be more economically viable, especially at large scales.

Making the Right Choice for Your Goal

The ideal catalyst is defined by your specific objective, feedstock, and economic constraints.

- If your primary focus is maximizing high-octane gasoline: Use highly acidic microporous zeolites like ZSM-5 to promote the formation of valuable aromatic compounds.

- If your primary focus is processing mixed or contaminated plastic waste: Consider robust, lower-cost options like spent FCC catalysts or basic metal oxides that are more resistant to certain poisons.

- If your primary focus is producing chemical feedstocks like olefins: Tailor your selection towards catalysts like modified zeolites or specific metal oxides known to favor olefin production.

Ultimately, mastering catalytic pyrolysis is about understanding how to use these powerful materials to precisely control chemical reactions on a massive scale.

Summary Table:

| Catalyst Family | Key Examples | Primary Function & Benefit |

|---|---|---|

| Zeolites | ZSM-5, H-Y | Cracks polymers into high-octane gasoline; highly selective. |

| Mesoporous Materials | MCM-41, SBA-15 | Large pores handle bulky polymers; reduces deactivation. |

| Metal Oxides | Al₂O₃, MgO | Lower-cost option; provides acidity/basicity for cracking. |

| FCC Catalysts | Spent FCC Catalyst | Cost-effective; bridges recycling with refinery processes. |

Ready to optimize your plastic pyrolysis process with the right catalysts?

KINTEK specializes in providing high-performance laboratory equipment and consumables for advanced recycling research and development. Whether you are testing catalyst efficiency, analyzing product yields, or scaling your process, our precise and reliable tools are designed to meet the demanding needs of the industry.

We help you:

- Accelerate R&D with equipment for precise temperature control and reaction monitoring.

- Improve Catalyst Selection with analytical tools to test performance and deactivation.

- Scale Your Process with robust lab-scale systems that provide accurate data for pilot and industrial scaling.

Let's turn your plastic waste into valuable resources. Contact our experts today to discuss how KINTEK can support your catalytic pyrolysis projects!

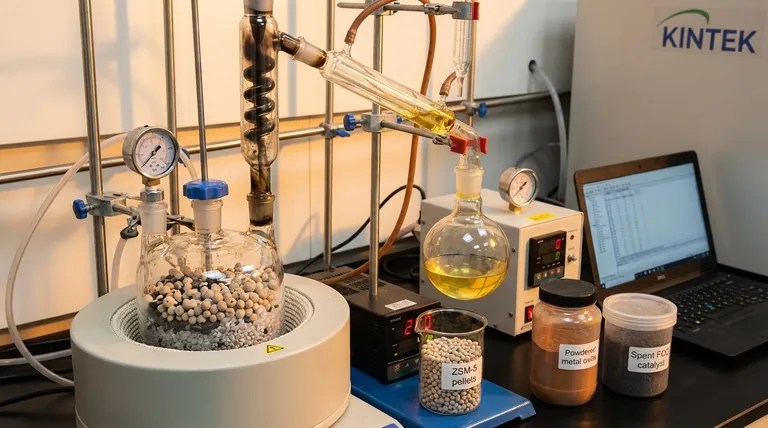

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Custom PTFE Teflon Parts Manufacturer for Magnetic Stirring Bar

- Custom PTFE Teflon Parts Manufacturer for PTFE Buchner Funnel and Triangular Funnel

- Bomb Type Probe for Steelmaking Production Process

People Also Ask

- What are the specific applications of PTFE in micro-batch slug flow systems? Enhance Your Microfluidic Reaction Purity

- What are alloys in simple words? Unlock the Power of Engineered Materials

- What are the four main types of sensors? A Guide to Power Source and Signal Type

- How are PTFE gaskets utilized for POEGMA electrolyte conductivity? Ensure Precision in Electrochemical Measurements

- Why are PTFE laboratory consumables required when testing stainless steel against organic acids? Ensure Data Integrity