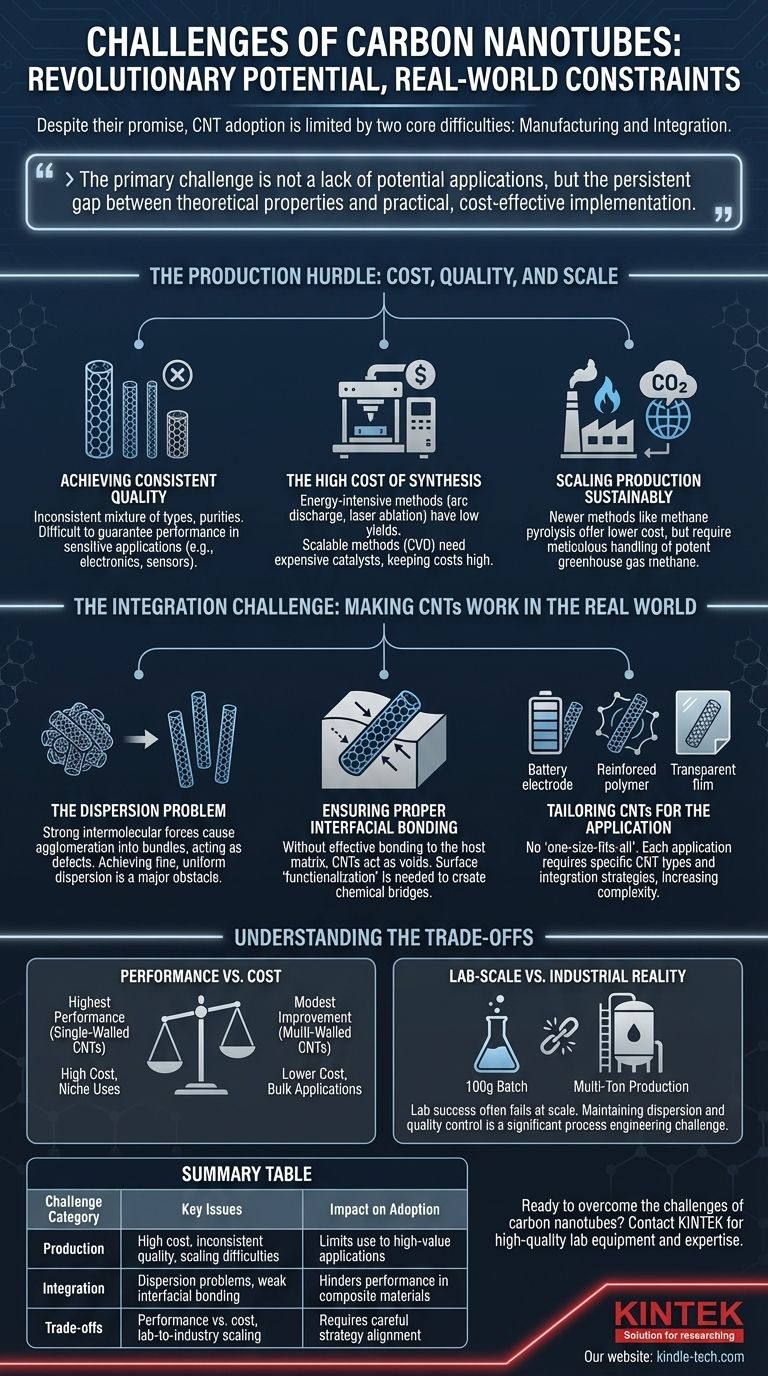

Despite their revolutionary potential, the widespread adoption of carbon nanotubes (CNTs) is fundamentally constrained by two core difficulties. The first is manufacturing: producing high-quality, uniform CNTs at a commercially viable scale and cost remains a significant engineering hurdle. The second is integration: effectively dispersing these microscopic tubes into other materials to translate their remarkable properties from the nano-scale to a macro-scale product.

The primary challenge is not a lack of potential applications for carbon nanotubes, but the persistent gap between their theoretical properties and their practical, cost-effective implementation in real-world systems.

The Production Hurdle: Cost, Quality, and Scale

The journey from raw carbon to a functional nanotube is fraught with technical and economic challenges. The method of synthesis directly impacts the final quality, cost, and environmental footprint.

Achieving Consistent Quality

The extraordinary properties of a CNT are dictated by its specific structure—its diameter, length, and chirality (the angle of its atomic lattice).

Most industrial production methods create a mixture of different types of CNTs with varying levels of purity. This inconsistency makes it difficult to guarantee predictable performance in sensitive applications like electronics or sensors.

Even newer, "greener" production methods, such as using captured carbon dioxide, often raise concerns about the lower quality and purity of the resulting material.

The High Cost of Synthesis

Traditional methods for creating high-purity CNTs, such as arc discharge or laser ablation, are extremely energy-intensive and have very low yields.

While chemical vapor deposition (CVD) is more scalable, it relies on expensive catalysts and complex process controls to manage nanotube growth, keeping costs high for premium-grade material. This economic barrier limits their use to high-value applications.

Scaling Production Sustainably

Newer methods like methane pyrolysis, which splits natural gas into valuable hydrogen and solid carbon, offer a path to lower-cost production.

However, this process requires meticulous handling to prevent the release of methane, a greenhouse gas far more potent than carbon dioxide. The engineering required to ensure this process is truly "green" adds its own layer of complexity and cost.

The Integration Challenge: Making CNTs Work in the Real World

Simply adding CNTs to a material does not guarantee improved performance. The true challenge lies in making the nanotubes work in concert with their host material.

The Dispersion Problem

Due to powerful intermolecular forces (van der Waals forces), CNTs have an extremely strong tendency to clump together into bundles, a process known as agglomeration.

These clumps act as defects rather than reinforcements, often weakening the final material. Achieving a fine, uniform dispersion of individual nanotubes within a matrix (like a polymer, concrete, or metal) is arguably the single greatest obstacle in CNT composites.

Ensuring Proper Interfacial Bonding

Once dispersed, the CNTs must bond effectively with the surrounding host material, or "matrix." This interface is where properties like mechanical strength or electrical conductivity are transferred.

If the bond is weak, the nanotube essentially acts as a void. Significant research is dedicated to "functionalizing" the surface of CNTs—adding chemical groups that act as a bridge to the matrix—to solve this interfacial challenge.

Tailoring CNTs for the Application

The ideal CNT for a battery electrode is fundamentally different from the one needed for a fiber-reinforced polymer or a transparent conductive film.

This means there is no "one-size-fits-all" solution. Each application requires a specific type of CNT and a unique integration strategy, which dramatically increases the complexity of development and supply chain management.

Understanding the Trade-offs

Successfully implementing CNTs requires a pragmatic understanding of the compromises involved. The ideal is rarely achievable in practice.

Performance vs. Cost

The highest-quality, single-walled CNTs with specific chiralities offer the most spectacular performance gains, but their cost is prohibitive for almost anything but advanced research and niche electronics.

Most commercial applications, such as conductive polymers or concrete, use lower-cost multi-walled CNTs (MWCNTs). These offer more modest improvements but are economically viable for bulk materials.

Lab-Scale Success vs. Industrial Reality

A formulation that works perfectly in a 100-gram laboratory batch often fails when scaled to multi-ton industrial production.

Maintaining uniform dispersion and consistent quality control at a large scale is a significant leap in process engineering that derails many promising CNT-enhanced products.

Environmental and Safety Concerns

While solid CNTs are stable, the handling of raw, aerosolized nanotubes in a manufacturing environment requires strict safety protocols to mitigate potential respiratory health risks. This adds operational overhead and requires specialized facilities.

Making the Right Choice for Your Goal

Navigating these challenges requires aligning your strategy with your primary objective. There is no single correct approach; the right path depends on your specific application and constraints.

- If your primary focus is cutting-edge performance (e.g., advanced sensors, high-frequency electronics): Prioritize securing a source for high-purity, specialized CNTs where the extreme cost is justified by unparalleled capability.

- If your primary focus is enhancing bulk materials (e.g., composites, concrete, asphalt): Concentrate your efforts on dispersion technology and processing, as using lower-cost MWCNTs effectively is the key to a positive ROI.

- If your primary focus is next-generation batteries: Focus on solving the interfacial challenges to ensure CNTs effectively bond with anode and cathode materials to improve conductivity and cycle life.

Ultimately, harnessing the power of carbon nanotubes is less about their inherent properties and more about mastering the science of their production and integration.

Summary Table:

| Challenge Category | Key Issues | Impact on Adoption |

|---|---|---|

| Production | High cost, inconsistent quality, scaling difficulties | Limits use to high-value applications |

| Integration | Dispersion problems, weak interfacial bonding | Hinders performance in composite materials |

| Trade-offs | Performance vs. cost, lab-to-industry scaling | Requires careful strategy alignment |

Ready to overcome the challenges of carbon nanotubes in your lab? KINTEK specializes in providing high-quality lab equipment and consumables tailored to your research and production needs. Whether you're working on cutting-edge electronics or enhancing bulk materials, our expertise can help you navigate CNT integration complexities. Contact us today to discover how our solutions can optimize your workflow and accelerate your innovations!

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- CVD Diamond for Thermal Management Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

People Also Ask

- How does CVD work graphene? A Guide to Large-Scale, High-Quality Production

- What is the use of chemical vapor deposition? Create High-Performance Thin Films & Coatings

- How is diamond coating done? A Guide to CVD Methods for Superior Performance

- What are the characteristics of CVD diamond? Unlocking Superior Performance for Industrial Tools

- What is the difference between physical and chemical vapour deposition? A Guide to PVD vs. CVD Coating

- What is deposition of a thin solid film on a substrate from vapor precursors? A Guide to PVD vs. CVD

- What is a CVD machine? Unlock the Power of High-Performance Thin Film Deposition

- How much does diamond-like carbon cost? A Guide to DLC Coating Service Pricing