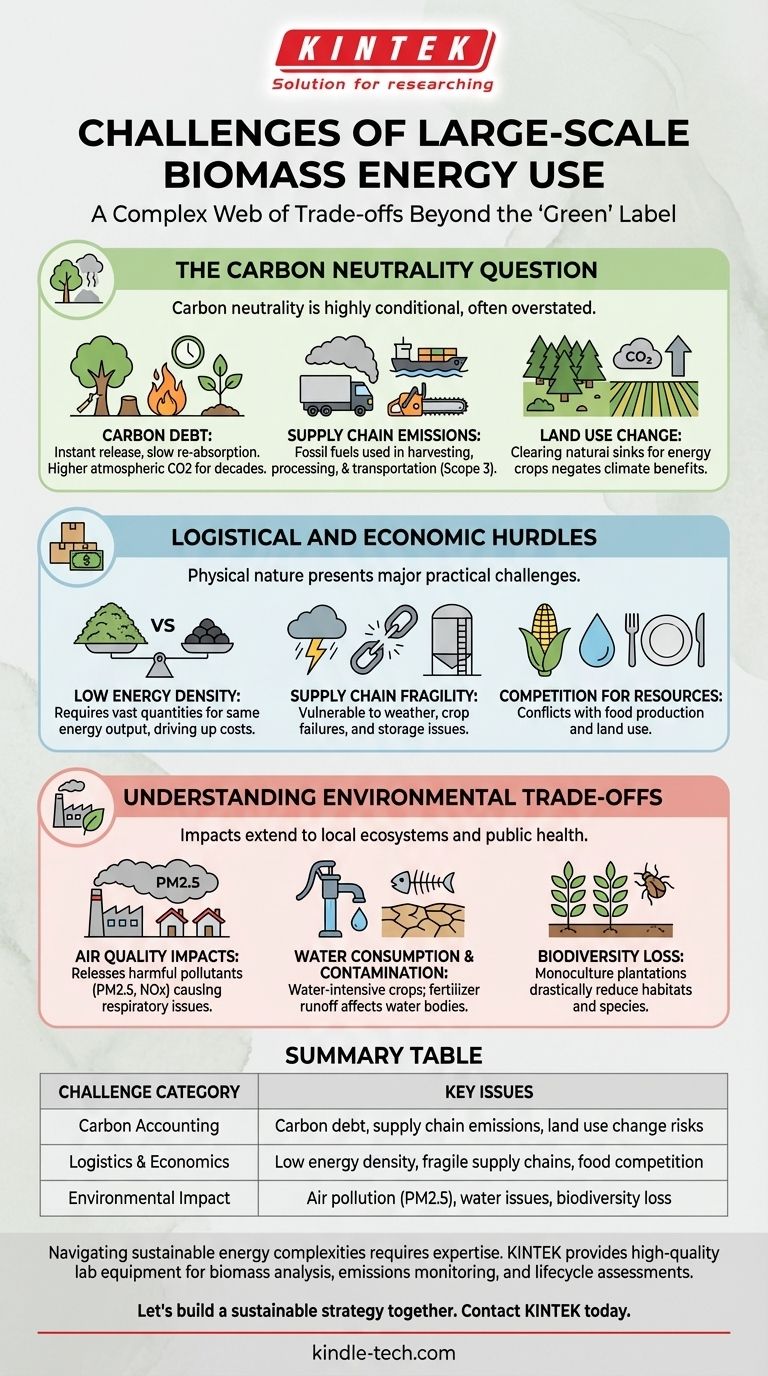

While often presented as a straightforward green alternative, large-scale biomass energy is constrained by significant challenges spanning land use, carbon accounting, supply chain logistics, and direct environmental impacts. These hurdles question its role as a primary solution for decarbonization and reveal a complex web of trade-offs that are often overlooked in high-level discussions.

The central challenge of large-scale biomass energy is that its sustainability is not guaranteed. Its popular claim of "carbon neutrality" is highly conditional, depending entirely on feedstock sourcing, land management practices, and supply chain efficiency, making it a far more nuanced and potentially problematic solution than wind or solar power.

The Carbon Neutrality Question

The core appeal of biomass is the idea that it is "carbon neutral"—that the carbon dioxide released during combustion is simply the same carbon absorbed by the plant during its growth. This concept, however, is a dangerous oversimplification.

The Problem of "Carbon Debt"

When a tree is cut down and burned for energy, its stored carbon is released into the atmosphere almost instantly. However, it can take decades, or even a century, for a new tree to grow and re-absorb an equivalent amount of CO2.

This time lag creates a carbon debt. For a significant period, using forest biomass for energy can result in higher atmospheric carbon concentrations than burning fossil fuels to produce the same amount of energy.

Emissions from the Supply Chain

The journey of biomass from field or forest to power plant is energy-intensive. Fossil fuels are consumed by chainsaws, harvesters, trucks, and ships used for harvesting, processing, and transportation.

These "Scope 3" emissions are often excluded from simplistic carbon calculations but are a very real part of the total climate impact of biomass energy.

The Risk of Land Use Change

The most severe risk comes from land use change. If natural forests, grasslands, or peatlands—which are massive carbon sinks—are cleared to grow dedicated "energy crops," the initial release of carbon from the soil and displaced vegetation can be immense. This can negate any potential climate benefits for centuries.

Logistical and Economic Hurdles

Beyond carbon accounting, the physical nature of biomass presents major practical challenges for large-scale deployment.

Low Energy Density

Biomass is bulky and has a low energy density compared to fossil fuels. This means vast quantities of wood pellets, corn stover, or other feedstocks must be transported and stored to generate the same amount of energy as a much smaller volume of coal or natural gas. This drives up transportation costs and logistical complexity.

Supply Chain Fragility

A large biomass power plant requires a massive, consistent, and reliable supply of feedstock. This creates a complex supply chain that is vulnerable to weather events, crop failures, and transportation disruptions. Storing large amounts of biomass is also challenging, as it can rot, decompose, or even spontaneously combust if not managed properly.

Competition for Resources

The land, water, and crops used for biomass energy are often the same resources needed for food production and animal feed. Creating a large new demand for biomass can increase food prices, create land-use conflicts, and raise significant ethical questions about resource allocation.

Understanding the Environmental Trade-offs

The impact of biomass energy extends beyond carbon to local ecosystems and public health. A narrow focus on CO2 can obscure these critical trade-offs.

Air Quality Impacts

Burning biomass releases harmful air pollutants, including particulate matter (PM2.5), nitrogen oxides (NOx), volatile organic compounds (VOCs), and carbon monoxide. In communities near large biomass facilities, this can lead to significant respiratory health issues, undermining the "clean" energy label.

Water Consumption and Contamination

Growing dedicated energy crops, especially species like corn or switchgrass, can be highly water-intensive. This places a strain on local water resources, particularly in arid regions. Furthermore, the use of fertilizers and pesticides can lead to nutrient runoff, contaminating nearby rivers and lakes.

Biodiversity Loss

Converting diverse, natural ecosystems into monoculture plantations of a single energy crop drastically reduces biodiversity. This practice eliminates habitats for countless species of plants, insects, and animals, leading to a sterile and ecologically fragile landscape.

A Pragmatic Approach to Biomass Implementation

To deploy biomass energy responsibly, you must shift your perspective from seeing it as a silver-bullet replacement for fossil fuels to viewing it as a niche solution for specific circumstances.

- If your primary focus is rapid decarbonization: Prioritize truly zero-emission sources like wind, solar, and nuclear, using biomass only in niche applications where sustainably-sourced waste is the feedstock.

- If your goal is to utilize existing waste streams: Focus on small-scale projects that use genuine agricultural residues, forestry trimmings, or sorted municipal solid waste to generate local energy and avoid the pitfalls of dedicated energy crops.

- If you are a policymaker evaluating large-scale projects: Mandate rigorous, full-lifecycle carbon accounting that includes land use change and supply chain emissions, and enforce strict sustainability criteria for all sourcing.

Ultimately, the viability of biomass energy hinges on a disciplined and localized approach that treats it as one component of a broader energy strategy, not as a standalone solution.

Summary Table:

| Challenge Category | Key Issues |

|---|---|

| Carbon Accounting | Carbon debt, supply chain emissions, land use change risks |

| Logistics & Economics | Low energy density, fragile supply chains, competition with food production |

| Environmental Impact | Air pollution (PM2.5), water consumption/contamination, biodiversity loss |

Navigating the complexities of sustainable energy requires the right tools and expertise. KINTEK specializes in providing high-quality lab equipment and consumables for analyzing biomass feedstocks, monitoring emissions, and conducting life-cycle assessments. Whether you're a researcher, policymaker, or energy producer, our solutions help you make data-driven decisions for a responsible energy future.

Let's build a sustainable strategy together. Contact KINTEK today to discuss your laboratory needs.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Large Vertical Graphite Vacuum Graphitization Furnace

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

People Also Ask

- What is the yield of pyrolysis gas? A Guide to Controlling Your Output (20-35%)

- What is the most common method used for synthesis of nanomaterials? A Guide to Dominant Techniques

- How do you evaporate a high boiling point solvent? Master Low-Pressure Techniques to Protect Your Samples

- Why you should avoid water contamination when performing FTIR measurements using NaCl or KBr plates? Protect Your Equipment & Data Integrity

- What heating treatment can be used to strengthen the structure of a metal? Master Hardening, Tempering & More

- When using a rotavap Why should you avoid bumping? Prevent Catastrophic Sample Loss and Contamination

- What are the functions of laboratory shakers and centrifuges in phosphorus extraction? Optimize Sample Purification

- What are the applications of compressed air systems? Powering Industry from Manufacturing to Pharma