The primary types of Chemical Vapor Deposition (CVD) are categorized by their operating pressure and the energy source used to drive the reaction. This includes processes like Atmospheric Pressure CVD (APCVD), which is fast but less uniform; Low-Pressure CVD (LPCVD), which offers excellent uniformity; and Plasma-Enhanced CVD (PECVD), which enables deposition at lower temperatures. The specific choice depends entirely on the required film quality, the substrate material, and manufacturing constraints like speed and cost.

The selection of a CVD process is not about finding the "best" method, but about managing a series of engineering trade-offs. The core decision revolves around balancing deposition speed, film quality, and the processing temperature your substrate can tolerate.

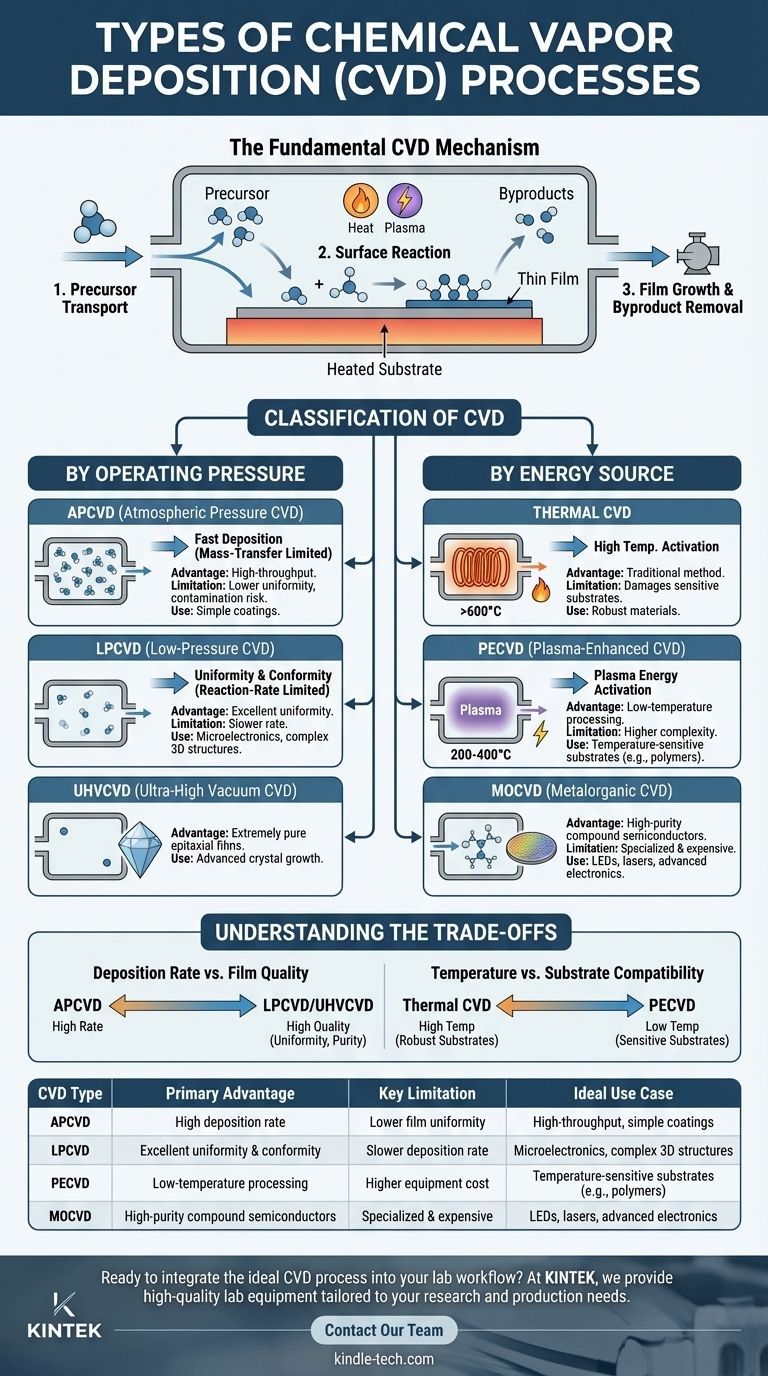

The Fundamental CVD Mechanism

Before comparing types, it's crucial to understand that all CVD processes share a common sequence of events. This foundation helps explain why variations like pressure or energy source have such a significant impact on the final result.

Step 1: Precursor Transport

A volatile chemical, known as a precursor, is introduced into a reaction chamber in gaseous form. This precursor contains the atoms you wish to deposit onto your target surface, or substrate.

Step 2: Surface Reaction

The precursor gas adsorbs onto the heated substrate. The energy present—either from heat or another source—causes the precursor molecules to decompose or react with other gases. This chemical reaction is the heart of the process.

Step 3: Film Growth & Byproduct Removal

The desired atoms from the reaction bond to the substrate, forming a thin, solid film. Gaseous byproducts from the reaction are desorbed from the surface and transported out of the chamber by a continuous gas flow or vacuum pump.

Classification by Operating Pressure

The pressure inside the reaction chamber is one of the most fundamental variables. It directly controls how reactant gases move and interact, defining the limits of the deposition rate and the quality of the resulting film.

Atmospheric Pressure CVD (APCVD)

This process operates at normal atmospheric pressure. Because of the high concentration of gas molecules, the reaction rate is primarily limited by how fast the precursors can diffuse through the gas to the substrate surface. This is known as being mass-transfer limited.

The result is a very high deposition rate, making APCVD suitable for high-throughput manufacturing. However, this can lead to lower film uniformity and a higher risk of gas-phase particle formation, which can contaminate the film.

Low-Pressure CVD (LPCVD)

LPCVD operates in a vacuum, at pressures significantly below one atmosphere. With fewer gas molecules present, precursors can easily reach the substrate. The deposition rate is now limited by the speed of the actual chemical reaction on the surface. This is known as being reaction-rate limited.

This process is slower than APCVD, but it produces films with outstanding uniformity and conformity, even over complex, three-dimensional structures. This makes it a cornerstone of microelectronics manufacturing.

Ultra-High Vacuum CVD (UHVCVD)

This is an extreme version of LPCVD, operating under ultra-high vacuum conditions. The exceptionally low pressure minimizes contaminants, allowing for the growth of extremely pure, high-quality epitaxial films where the crystal structure of the film perfectly matches the substrate.

Classification by Energy Source

While pressure controls the transport of gases, the energy source dictates how the chemical reaction is initiated. The choice of energy source is often determined by the temperature limitations of the substrate.

Thermal CVD

This is the most traditional form, where high temperature (typically >600°C) is the sole energy source used to break down the precursor molecules. Both APCVD and LPCVD are often forms of Thermal CVD. Its main limitation is that the high temperatures can damage or destroy sensitive substrates, such as plastics or certain electronic components.

Plasma-Enhanced CVD (PECVD)

PECVD uses an electric field to generate a plasma (an ionized gas) within the chamber. This energetic plasma provides the energy to drive the chemical reaction, allowing high-quality films to be deposited at much lower temperatures (typically 200-400°C). This is the key advantage of PECVD, making it indispensable for depositing films on temperature-sensitive materials.

Metalorganic CVD (MOCVD)

MOCVD is not defined by its pressure or energy source but by its use of metalorganic precursors. This technique is exceptionally versatile and is a critical process in manufacturing compound semiconductors used in LEDs, lasers, and high-frequency electronics. It can be performed under various pressure and energy conditions.

Understanding the Trade-offs

Choosing a CVD method involves a clear understanding of its inherent compromises. There is no single solution that is fast, high-quality, low-temperature, and low-cost.

Deposition Rate vs. Film Quality

APCVD offers the highest deposition rates, ideal for thick coatings where minor imperfections are acceptable. In contrast, LPCVD and UHVCVD sacrifice speed to achieve superior uniformity, purity, and the ability to coat complex surfaces evenly.

Temperature vs. Substrate Compatibility

Thermal CVD is often simpler but is restricted to substrates that can withstand high temperatures. PECVD's primary advantage is its low-temperature operation, opening up a vast range of materials (like polymers or fully fabricated integrated circuits) that would be damaged by thermal processes.

Simplicity vs. Complexity

Systems for APCVD are generally simpler and less expensive. Introducing vacuum systems for LPCVD or RF power sources for PECVD adds significant cost and complexity to the equipment and process control.

Selecting the Right CVD Process

Your final choice must be aligned with the primary objective for your thin film.

- If your primary focus is high-throughput production of simple coatings: APCVD is often the most cost-effective choice due to its high deposition rate.

- If your primary focus is excellent film uniformity and conformity over complex shapes: LPCVD is the industry standard for applications demanding precision.

- If your primary focus is depositing a high-quality film on a temperature-sensitive substrate: PECVD is the ideal solution because it replaces high heat with plasma energy.

- If your primary focus is creating highly-pure, crystalline compound semiconductor films: MOCVD is the essential, specialized technique for advanced electronics and optoelectronics.

By understanding these core principles and trade-offs, you can confidently select the chemical vapor deposition process that best meets your specific technical and economic goals.

Summary Table:

| CVD Type | Primary Advantage | Key Limitation | Ideal Use Case |

|---|---|---|---|

| APCVD | High deposition rate | Lower film uniformity | High-throughput, simple coatings |

| LPCVD | Excellent uniformity & conformity | Slower deposition rate | Microelectronics, complex 3D structures |

| PECVD | Low-temperature processing | Higher equipment cost | Temperature-sensitive substrates (e.g., polymers) |

| MOCVD | High-purity compound semiconductors | Specialized & expensive | LEDs, lasers, advanced electronics |

Ready to integrate the ideal CVD process into your lab workflow?

At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to your specific research and production needs. Whether you require the high throughput of APCVD, the precision of LPCVD, the low-temperature capabilities of PECVD, or the specialized performance of MOCVD, our experts can help you select and implement the perfect solution to enhance your results and efficiency.

Contact our team today to discuss your project requirements and discover how KINTEK can support your laboratory's success.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings